- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Maize/corn roasting machine

-

Voltage:

-

220v

-

Heating method:

-

electric or gas or diesel

-

Size:

-

6*1.1*1.6m

-

Capacity:

-

100-200kg/h

-

material quality:

-

stainless steel

-

Type:

-

Commercial

-

Speed Motor:

-

0.75kw

-

After Warranty Service:

-

Field maintenance and repair service

Quick Details

-

Brand Name:

-

hongle

-

Place of Origin:

-

Henan, China

-

Weight:

-

2500 KG, 980kg

-

Product name:

-

Maize/corn roasting machine

-

Voltage:

-

220v

-

Heating method:

-

electric or gas or diesel

-

Size:

-

6*1.1*1.6m

-

Capacity:

-

100-200kg/h

-

material quality:

-

stainless steel

-

Type:

-

Commercial

-

Speed Motor:

-

0.75kw

-

After Warranty Service:

-

Field maintenance and repair service

Product Description

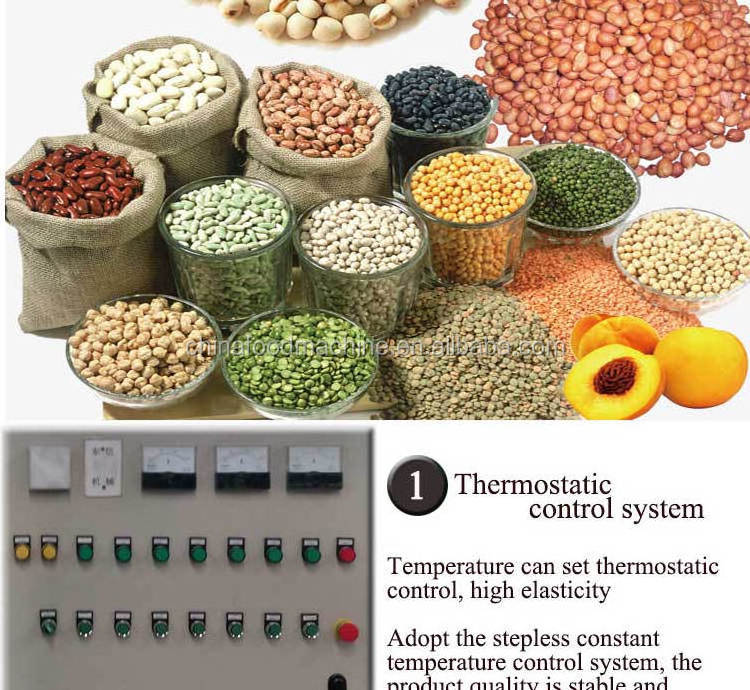

Maize/corn roasting machine

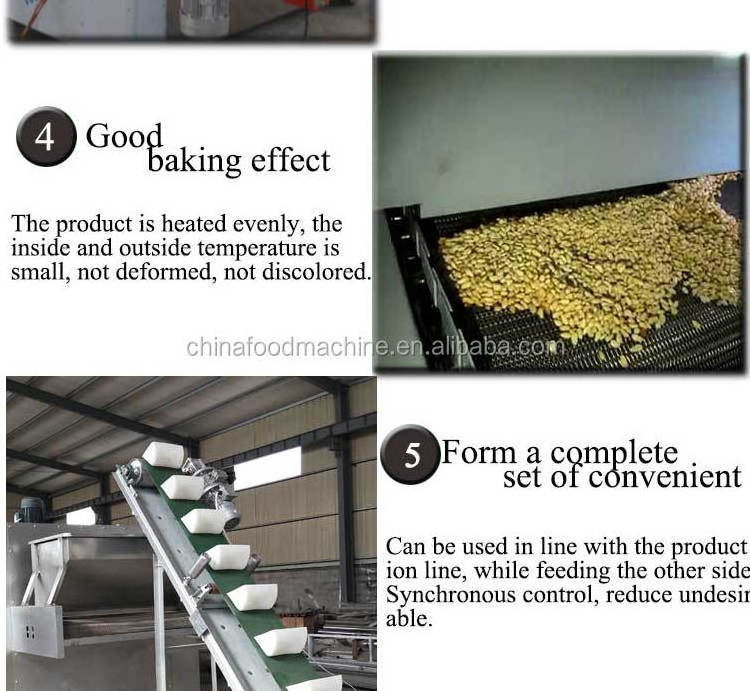

1. Material properties: Product shape: granular Equipment selection: belt dryer Production material: Material contact mesh belt is stainless steel or carbon steel Heat source: natural gas, liquefied gas, kerosene, diesel, electricity 2. Analysis of drying process: Drying box is divided into: high temperature zone, low temperature zone, cooling zone (also not necessary). The materials go through three temperature zones, namely, high temperature, low temperature drying (baking), and cooling. The processed finished product is cool, which is convenient for processing, packaging or storage. The drying process uses the hot and humid gas with the highest moisture content when the material enters the drying chamber. It is convenient for the moisture inside the material to quickly absorb heat, and it can be evenly dried inside and outside during the drying process. After the moisture evaporates, it is discharged from the moisture exhaust pipe to the dry outdoors with the air medium (damp and hot air). Keep the air in the workshop clean. 3: The drying heat source adopts natural gas, liquefied gas, kerosene, diesel, electric heating heat source, adjustable temperature, long operating life, and direct heating above the material. Normal temperature----The high temperature in the box of 200℃ makes the moisture in the material quickly absorb heat and volatilize. The temperature in the drying chamber can be controlled by an instrument, which helps to ensure the output and quality of the dried materials. 4: The transmission mode adopts stepless speed regulation device, and the running speed is adjustable. It is convenient to control the drying quality of materials. The conveying material adopts the mesh belt structure to avoid the material being too fine and missing. The hot air fan circulates in the drying tunnel, and the wind speed is below 0.1 m/s, which will not cause dust to fly. The mesh belt runs smoothly and vibrates, and the feeding part is equipped with a star feeder to keep the material spread evenly. 5. The complete set of drying process is highly automated, stainless steel or carbon steel where the material touches, and the high temperature part of the cabinet is made of high temperature cotton insulation.

|

Model

|

HL-4600

|

|

Temperature

|

normal temperature—260℃

|

|

Drying length of equipment

|

8 meters

|

|

Equipment height

|

2.3 meters

|

|

Mesh belt width

|

1.2---1.6 meters

|

|

Power

|

1.5kw

|

|

Voltage

|

380v

|

|

Equipment dimensions

|

8×2.1×2.3 meters

|

technical parameter

Packaging & Shipping

PACKAGE:

Standard export carton packing.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.

Hot Searches