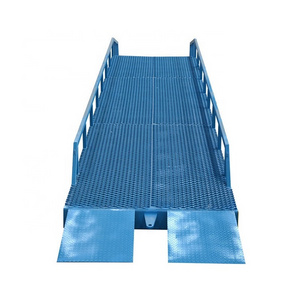

The mobile boarding bridge is a bridge equipment used between forklifts and trucks to facilitate loading and unloading of goods. It is suitable for places where there is no loading and unloading platform on site or where mobile loading and unloading of goods is required. It only requires one person to operate and does not require a power source to achieve rapid loading and unloading of goods.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

custom to your needs

-

Min. Lifting Height:

-

1100mm

-

Table Size:

-

custom to your needs

-

Overall Dimensions:

-

custom to your needs

-

Weight:

-

8000 kg, 6-20T

-

Marketing Type:

-

New Product 2024

-

Operation way:

-

Manual

-

Product name:

-

mobile boarding bridge

-

Keywords:

-

loading and unloading platform

-

Type:

-

Hydraulic Cylinder Drive

-

Application:

-

Logistics Warehouse

-

Usage:

-

Goods Lift Cargo Lift

-

Name:

-

Warehouse Mobile Dock Ramp

-

Material:

-

High Strength Manganese Steel

-

Lift Drive:

-

Manual or other drive method

Quick Details

-

Warranty:

-

1 Year

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

shunyuan

-

Power:

-

custom to your needs

-

Min. Lifting Height:

-

1100mm

-

Table Size:

-

custom to your needs

-

Overall Dimensions:

-

custom to your needs

-

Weight:

-

8000 kg, 6-20T

-

Marketing Type:

-

New Product 2024

-

Operation way:

-

Manual

-

Product name:

-

mobile boarding bridge

-

Keywords:

-

loading and unloading platform

-

Type:

-

Hydraulic Cylinder Drive

-

Application:

-

Logistics Warehouse

-

Usage:

-

Goods Lift Cargo Lift

-

Name:

-

Warehouse Mobile Dock Ramp

-

Material:

-

High Strength Manganese Steel

-

Lift Drive:

-

Manual or other drive method

|

|

Overall dimensions (M) Height 1.5m including guardrails

|

Platform length (M) including tongue plate

|

Slope length (M)

|

Length of tongue plate (M)

|

Tail plate length (M)

|

Overall machine weight (T)

|

|

DCQ-Y-6

|

11.3*2*1.5

|

3

|

7.5

|

0.35

|

0.8

|

≈2.2

|

|

DCQ-Y-8

|

11.3*2*1.5

|

3

|

7.5

|

0.35

|

0.8

|

≈2.3

|

|

DCQ-Y-10

|

11.3*2*1.5

|

3

|

7.5

|

0.35

|

0.8

|

≈2.5

|

|

DCQ-Y-12

|

11.2*2.2*1.5

|

3

|

7.5

|

0.35

|

0.8

|

≈3

|

|

DCQ-Y-15

|

11.2*2.2*1.5

|

3

|

7.5

|

0.35

|

0.8

|

≈3.4

|

Product Description

-

Product performance description

-

It can not only reduce your labor intensity, but also double the efficiency of loading and unloading operations, speed up the flow of materials, and obtain greater economic benefits. Product specifications: 6, 8, 10, 12, 15 tons, used with forklifts, the equipment adopts manual hydraulic mode, no power supply is required, saving time and effort.

Details Images

1. When using the boarding bridge, keep the table surface stable and firm, and the fixed chain must be firmly fixed to the vehicle. The speed limit during hauling is 3 km/h.

2. During the descent of the boarding bridge, all personnel are strictly prohibited from climbing, and overloading operations are strictly prohibited during use of the boarding bridge.

3. The hydraulic oil used should be kept clean and should not be mixed with water and other impurities. It should be replaced every six months. Hydraulic oil is generally N32 in winter and N46 in summer. When the boarding bridge fails, the operation should be stopped immediately to eliminate the fault.

The countertop adopts a special diamond-shaped network board with reliable strength and can ensure long-term use without deformation. Its diamond-shaped mesh structure fully ensures excellent anti-skid performance and enables the forklift to have better gradeability and maneuverability. Even in rainy and snowy weather, normal use is still guaranteed. The main beam adopts national standard high-strength 25# steel, with stable and reliable quality.

The extended length of the upper platform allows enough space to adjust the loading and unloading angle during forklift operation to prevent slipping and make the operation safer;

It adopts large-tonnage outriggers and two auxiliary outriggers, which has strong supporting capacity and the axle is stable and durable;

The front axle adopts an integrated design;

The adjustable-length rope chain can easily hook the vehicle and make the boarding axle and the truck closely fit.

The axle design has a compact and solid structure to prevent axle deformation due to dynamic loads;

The equipped brake pads can effectively prevent the boarding bridge from shifting when loading and unloading trucks.

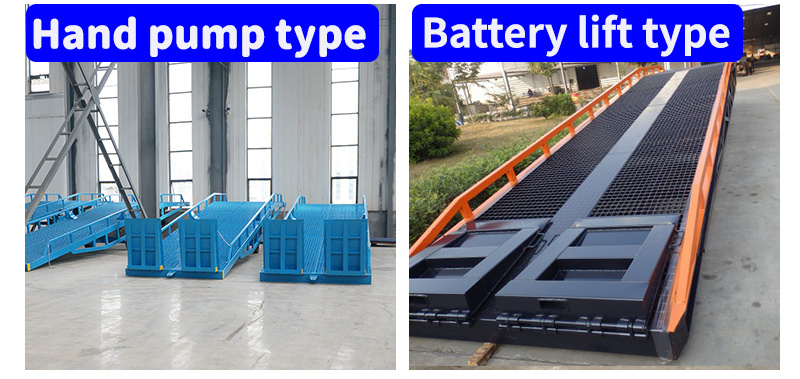

Using a hand-operated hydraulic pump as power, the height of the boarding bridge can be easily adjusted without the need for an external power supply.

Product Usage

-

-

Product usage introduction

-

Press the lifting handle to raise the boarding bridge above the floor of the carriage. When the vehicle is in place, loosen the oil return valve, lower the boarding bridge and smoothly connect the lip plate to the rear of the vehicle. Use a chain to secure the boarding bridge and the vehicle. At this time, the hydraulic system is not stressed and operations can begin. After the operation is completed, loosen the fixed chain, press the handle to raise the boarding bridge, drive away the vehicle, and reset the boarding bridge. Lift the tail of the boarding bridge and hang it on the vehicle to move it.

-

Application scenarios

Products can be specially designed according to the different needs of users in terms of appearance, size, load bearing, etc. It is suitable for large enterprises, warehouses, stations, terminals, warehousing and logistics bases, postal transportation, logistics distribution, etc. with frequent loading and unloading of trucks and different models.

Related Products

Packing&Shipping

Product and list packaging in wooden boxes

Company Introduction

It is a company specializing in hydraulic lifting machinery, aerial work platforms, logistics loading and unloading platforms, lifting stages, and aerial operations. An innovative enterprise integrating R&D, design, production and sales of cars, car lifts and other products. The company's products are now widely used in stations, docks, exhibition halls, museums, warehouses, airports, ports, banks, maintenance, decoration and other places, and can be customized and produced according to customer needs. The products are now sold to Shandong, Jiangxi, Hebei, Inner Mongolia, Guangzhou, Zhejiang, Beijing, Tianjin, Shanghai and other provincial and municipal areas. The company has a group of engineers and technical installation teams with rich experience, providing one-stop services from technical consultation to design, installation, commissioning, etc., with advanced R&D design, meticulous processing and production, good on-site installation, and sincere after-sales service For many years, the company has used advanced production technology and multiple controls to manage products and quality; the company has always adhered to the corporate philosophy and cooperative spirit of "integrity and trustworthiness, keeping pace with the times, performance first, unity and cooperation, and people-oriented" , and strive to build the integrity image of the company and the brand image of the product.

Our Services & Strength

Wholeheartedly create value for customers and realize their own value.

(1) A professional design, sales, production, quality inspection and installation team of 150 people, providing one-stop worry-free service;

(2) Workers are strictly trained, and each process is checked at all levels to prevent cutting corners;

(3) Provide product solutions for many domestic Fortune 500 companies and have rich experience in non-standard design and construction;

(4) Professional design engineers are stationed on-site to formulate customized design plans for the enterprise;

(5) Installation and after-sales personnel are stationed in various countries to provide comprehensive tracking services to solve your worries.

FAQ

1. Once the hydraulic oil becomes dark, sticky or contains foreign matter such as grit, it should be replaced in time.

2. Check the rollers, central shaft and bearings, cylinder pins and bearings, boom hinge shafts and bearings, etc. for wear. If there is any wear, repair or replace it immediately.

3. Some lubricating oil should be added to each part to extend the service life of the bearing.

4. Check all hydraulic pipes and joints. The pipes must not be damaged and the joints must not be loose. All joints must be tightened.

5. Remove and disassemble the lowering valve, blow out the plunger with compressed air, and then reinstall it.

Hot Searches