- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

69

-

Product Name:

-

Spiral Broach

-

Package:

-

Plastic Tube+Carton

-

Shipment:

-

By Express/Air/Sea

-

Material:

-

High Speed Steel

-

Application:

-

Groove Processing

-

Usage:

-

Broaching Keyways

-

Coating:

-

Requirement

-

Hardness:

-

Suitable

-

Heat Treatment Hardness:

-

63 - 67HRC

-

Machining Process:

-

Drilling Etc

Quick Details

-

Type:

-

Keyway Broach

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Bbestfor

-

Model Number:

-

69

-

Product Name:

-

Spiral Broach

-

Package:

-

Plastic Tube+Carton

-

Shipment:

-

By Express/Air/Sea

-

Material:

-

High Speed Steel

-

Application:

-

Groove Processing

-

Usage:

-

Broaching Keyways

-

Coating:

-

Requirement

-

Hardness:

-

Suitable

-

Heat Treatment Hardness:

-

63 - 67HRC

-

Machining Process:

-

Drilling Etc

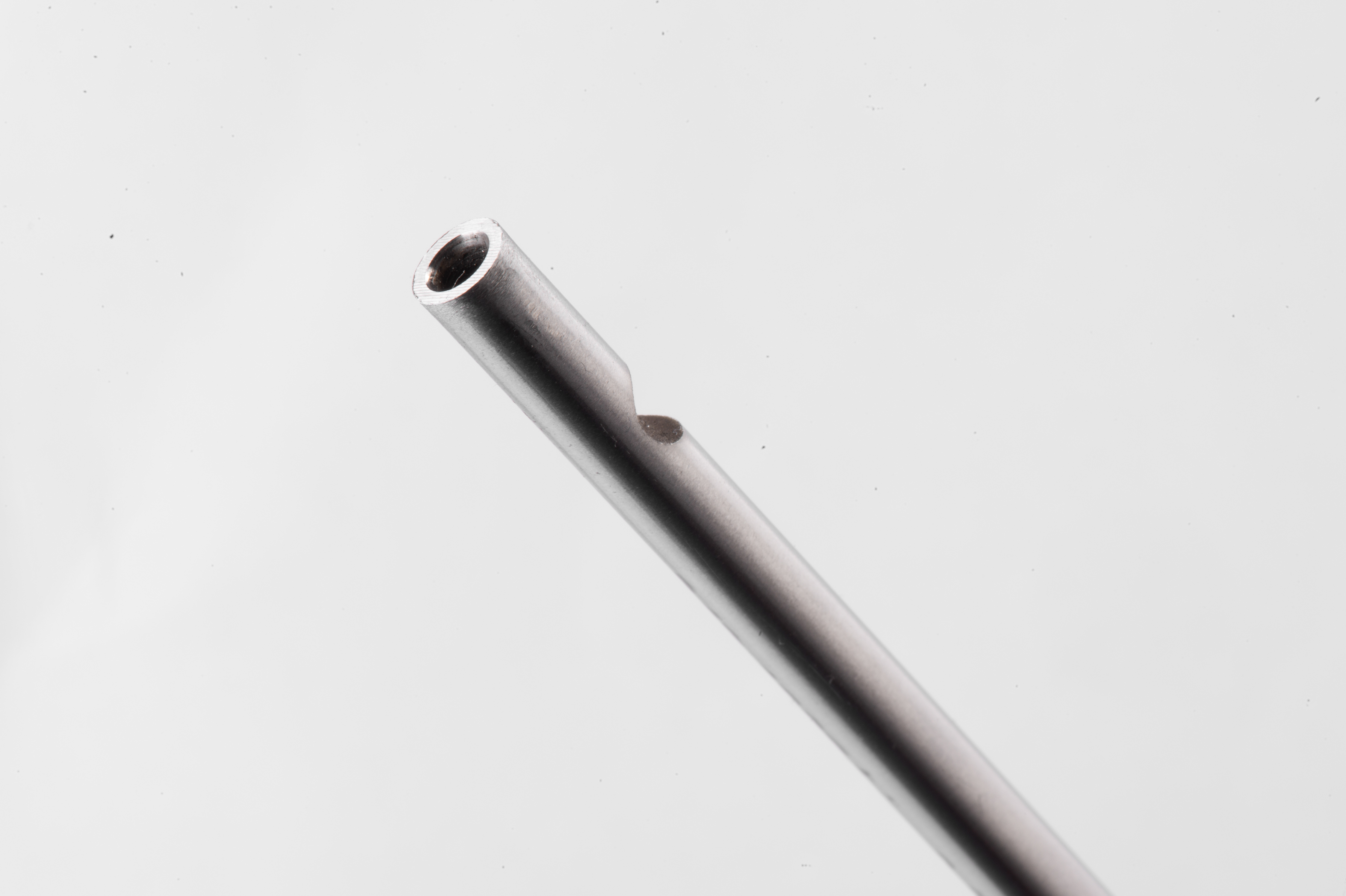

The broach is a forming tool used for broaching.

There are multiple rows of teeth on the surface of the cutting tool, and the size and shape of each row of teeth increase and change sequentially from the cutting end to the cutting end.

When the broach performs a cutting motion, each tooth cuts a certain thickness of metal from the workpiece, ultimately obtaining the required size and shape.

Broaches are commonly used in batch and mass production to process circular holes, keyways, flat surfaces, and formed surfaces, with high productivity.

Broaches are divided into inner and outer pullers according to the different parts of the processed surface; According to the different ways of working, it can be divided into broaches and push knives.

Pushing knives are commonly used to calibrate holes after heat treatment.

Material: Tungsten steel

| Model Number | Size(mm) | |||

| Square shank | Shank diameter | Total length | Slot length | |

| Customization | ||||