- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

22

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

rice hull briquette shaping machine

-

Capacity:

-

220-250 kg/h

-

Raw material:

-

sawdust, rice husk, wood powder etc with small size

-

Moisture content before making briquette:

-

8-12%

-

Final product shape:

-

square, pentagon and hexagon

-

The final product diameter:

-

60mm

-

Length of the briquette:

-

as you customized

-

OEM:

-

acceptable

-

Visit:

-

factory visit welcome

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mingyang

-

Weight (KG):

-

750 KG

-

Power (kW):

-

22

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

rice hull briquette shaping machine

-

Capacity:

-

220-250 kg/h

-

Raw material:

-

sawdust, rice husk, wood powder etc with small size

-

Moisture content before making briquette:

-

8-12%

-

Final product shape:

-

square, pentagon and hexagon

-

The final product diameter:

-

60mm

-

Length of the briquette:

-

as you customized

-

OEM:

-

acceptable

-

Visit:

-

factory visit welcome

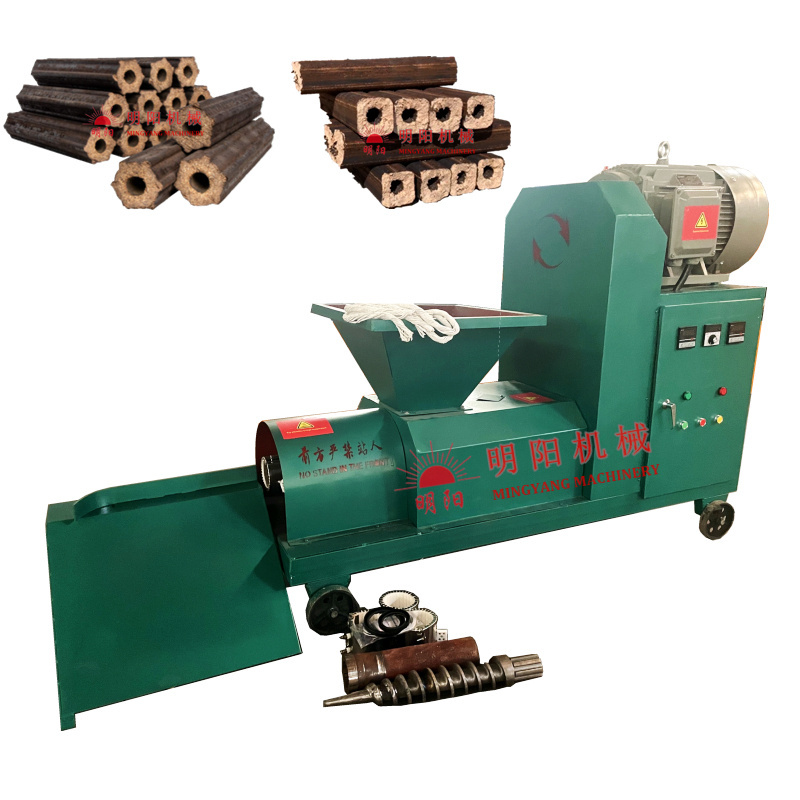

Rice hull briquette shaping machine/wood charcoal briquette machine/rice husk biomass sawdust briquette extruder

Packing detailed information of therice hull briquette shaping machine:

1) wooden case for packing one set rice hull briquette shaping machine;

2) for more sets rice hull briquette shaping machine or the product line, we use the standard container.

Main data of the rice hull briquette shaping machine:

| Type | ZBJ60-9 |

| Power | 15-18.5kw |

| Capacity | 220-250kg/h |

| Material content before making briquette | 8-12% |

| Material size before making briquette | 3-5mm |

| Weight | 650kg |

| Material packing size | 2.4*0.7*1.35m |

| Final product diameter | 60mm |

If you want to choose the suitable machine, you should pay attention of these factor:

A/ Introduction:

The briquettes are a kinds of biofuel substitube to coal and charcoal. They are used to heat industrial boilers in order to produce electricity from steam. The most common use of the briquettes are in the developing world, where energy sources are not widely available. There has been a move to the use of briquettes in the developed world through the use of cofiring, when the briquettes are combined with coal in order to creat the heat supplied to the boiler. This reduces carbon dioxide emissions by partially replacing coal used in power plants with materials that are already contained in the carbon cycle.

B/ Raw material(because different material will need different machines):

Any types of Agro-forestry waste and forest waste can be used for make briquettes Such as maize stalks, soybean stalks, broomcorn stalks, cotton stalks, rape stalks, peanut plants, sunflower stalks, bamboo sawdust, bagasse , wood chips, rice husk, coffee husk, coir pith, jute sticks, groundnut shells, Bamboo, wood, straw dust, Mustard stalk and cotton stalks ,nutshell, coconut shell. the moisture and diameter of the raw material ( before the raw material into the briquette machine, we should confirm that:

1. diameter (size): 3-5mm ( if can not meet the requirement, it will need a crusher ;

2. moisture: 8-12%, (if can not meet the requirement, it will need a dryer).

C/ Working Principle:

The main part of briquette machine is: screw, mold, heating ring. After heating at first, when the sawdust of other materials at diameter of 2-5mm be send into the briquette machine, the materials will be heating in the mold, then it be mold into briquette: sawdust stick with a hole in the middle.

D/ Final product:

the finished product you need (you need the sawdust briquette or the charcoal)

1)/ the sawdust briquette very popular in Europe market, and it can be used as one kind of fuel

a. The available shape: square, hexagonal, pentagon, pentagon with edge, hexagon with edge;

b. The available diameter could be: 50mm, 60mm, 70mm, 80mm and so on;

c. The available length could be :20cm, 30cm, 40cm, 50cm;

d. The feature of the final product : Specific gravity: 1300—1900kg/m Calorific value: 4500—5000kcal/kg

G/ Production line:

All the steps have been finished, this is the flow chart to make charcoal. You will be intersted in this chart. And then call me to talk about the detailed information.