*

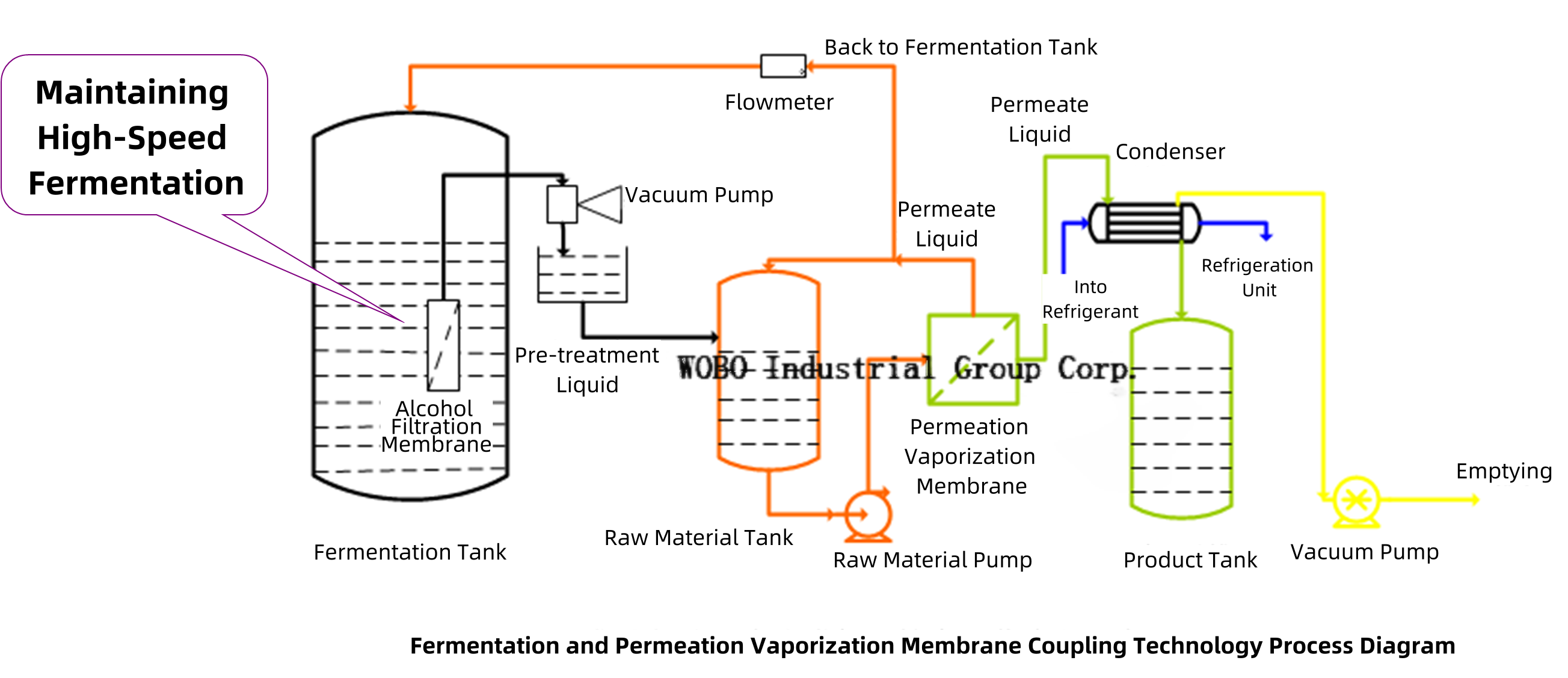

Fermentation efficiency increased by 2.3 times, and separation costs reduced by over 50%.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

0.9 kg

-

Size:

-

686*54 mm ( dimension for reference)

-

Weight (KG):

-

0.9 kg

-

Length/mm:

-

800±2

-

Inner diameter/mm:

-

7.6±0.2

-

Outer diameter/mm:

-

12.3±0.3

-

Operating method:

-

Cross-flow filtration

-

Installation:

-

Horizontal/Vertical

-

Permeation mode:

-

External pressure

-

Feed status:

-

Liquid/Gas

-

Feed temperature/°C:

-

0~70

-

Operating pressure/MPa:

-

≤1.0

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

WOBO

-

Material:

-

Wooden box, High-purity aluminum oxide, zirconium oxide

-

Weight:

-

0.9 kg

-

Size:

-

686*54 mm ( dimension for reference)

-

Weight (KG):

-

0.9 kg

-

Length/mm:

-

800±2

-

Inner diameter/mm:

-

7.6±0.2

-

Outer diameter/mm:

-

12.3±0.3

-

Operating method:

-

Cross-flow filtration

-

Installation:

-

Horizontal/Vertical

-

Permeation mode:

-

External pressure

-

Feed status:

-

Liquid/Gas

-

Feed temperature/°C:

-

0~70

-

Operating pressure/MPa:

-

≤1.0

Environmentally Friendly Efficient Recycling Alcoholic Membrane

Superior Quality Solvent-Selective Membrane Alumina-Zirconia Composite Pervaporation Membrane For Alcohol Separation

Technical Principle

The alcoholic membrane is a tubular composite membrane with an asymmetric structure. It is composed of a support layer made from high-purity inorganic materials such as aluminum oxide and zirconium oxide, which are processed at high temperatures. The support layer serves as a base, and on its surface, a dense membrane is prepared through a special process to act as the separation layer.

The membrane surface is smooth and free from defects, with uniform thickness. The bond between the separation membrane and the support layer is strong, providing excellent resistance to fouling and a long lifespan—typically lasting over 5 years. This type of membrane is suitable for concentrating low-concentration alcohol solutions.

The membrane surface is smooth and free from defects, with uniform thickness. The bond between the separation membrane and the support layer is strong, providing excellent resistance to fouling and a long lifespan—typically lasting over 5 years. This type of membrane is suitable for concentrating low-concentration alcohol solutions.

|

Model

|

|

WB-LSCM-80

|

|

|

Product Specifications

|

Length/mm

|

800±2

|

|

|

|

Inner Diameter/mm

|

7.6±0.2

|

|

|

|

Outer Diameter/mm

|

12.3±0.3

|

|

|

|

Material

|

High-purity aluminum oxide, zirconium oxide, polymers, etc.

|

|

|

Operating Parameters

|

Operating Mode

|

Crossflow filtration

|

|

|

|

Installation

|

Horizontal/Vertical

|

|

|

|

Permeation Mode

|

External pressure

|

|

|

|

Feed State

|

Liquid/Gaseous

|

|

|

|

Feed Temperature/℃

|

0~70

|

|

|

|

Operating Pressure/MPa

|

≤1.0

|

|

|

|

pH Range

|

1~14

|

|

Membrane Separation Process

The application of alcoholic membranes in fuel ethanol/n-butanol.

Technical Features:

Technical Features

1).

Efficient separation of alcohol and water

2). Reduced energy consumption

3). Purely physical separation process, no addition of foreign components

4). Mild operating conditions, easy for coupling

5).

Compact footprint

6).

High level of automation, easy to operate and maintain

Main Application Systems

* Enrichment of alcohol substances in fuel ethanol fermentation broth.

* Enrichment of alcohol substances in fuel n-butanol fermentation broth.

* Enrichment of alcohol substances in low-concentration alcohol solution.

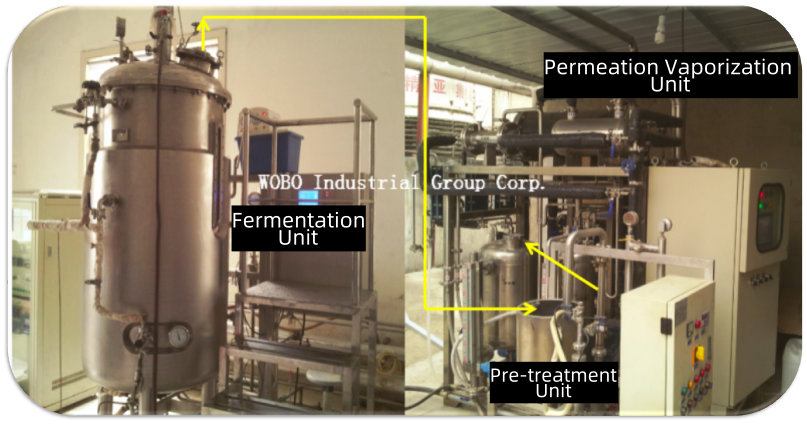

Detailed Photos

Project Case

Hot Searches