2.Wide range of products, fast sampling and prompt delivery.

3.Precision forging and CNC Machining as per customer;s drawings.

|

Product Name

|

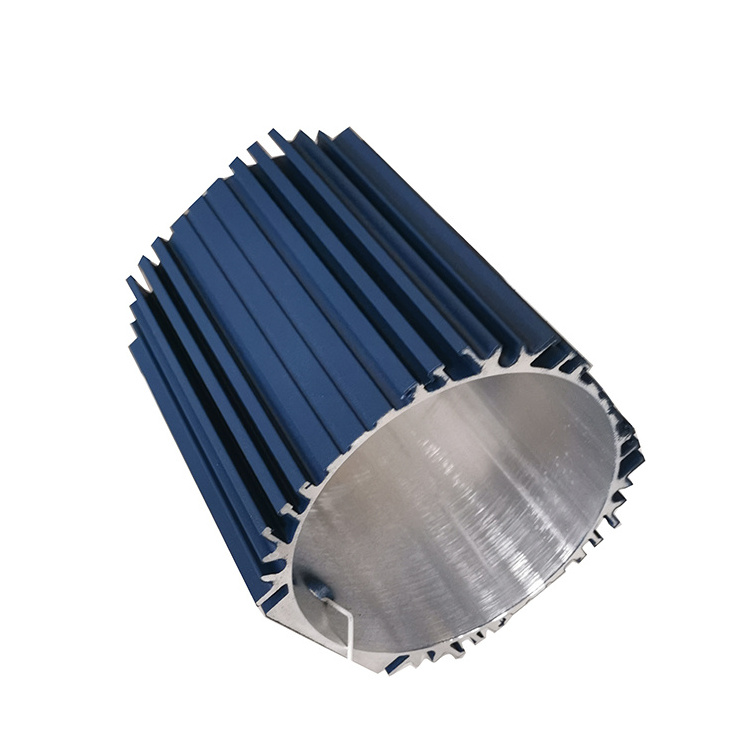

Custom Made CNC Machining Clear Anodized Aluminum Extrusion profiles,Precision 5 Axis Machining CNC Extrusion Aluminum Profiles

|

|

Deep processing ability

|

Drill hole, stretch bending, milling, welding, fabrication etc.

|

|

Material

|

6463,6061,6063,6005,7075,6082 etc.

|

|

Surface Finish

|

Pickling, Passivation, Sand-blasting, Shot-blasting, Electro-polishing, Buffing, Mirror-polishing, Zinc/Chrome Plating, Anodizing,Powder Coating,Electrophoretic painting etc.

|

|

Length

|

According to your requirement and also the max length which could be fit for 20" and 40" container

|

|

Tolerance

|

+/- 0.1mm

|

|

Application

|

windows and doors, aluminum profiles for LED light, aluminum profile for solar panel frame, aluminum handrail profile, aluminum

windows and doors, heat sink industry , etc |

|

Lead time

|

35 days for mold and samples, after confirmation of samples, mass production time is 25 days

|

|

Small Quantity

|

Is acceptable

|

|

Quality Control

|

Full Inspection

|

|

Surface Finish

|

Material Avaiable

|

|

Machined

|

All metals

|

|

Smooth

|

All metals+Plastic (e.g aluminum, steel,nylon, ABS)

|

|

Powder Coating

|

All metals ( e.g aluminum, steel)

|

|

Brushing

|

All metals ( e.g aluminum, steel)

|

|

Anodized Hardcoating

|

Aluminum and Titanium alloys

|

|

Electropolishing

|

Metal+plastic (e.g aluminum, ABS)

|

|

Bead Blasting

|

Aluminum and Titanium alloys

|

|

Anodized Clear or Color

|

Aluminum and Titanium alloys

|

|

Chrome /Zinc/Nickel Plating

|

Steel and Brass

|