- Product Details

- {{item.text}}

Quick Details

-

Machine Type:

-

bar soap making machine production line

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

hengyong

-

Weight (KG):

-

1600

-

Machine Type:

-

bar soap making machine production line

Product Description

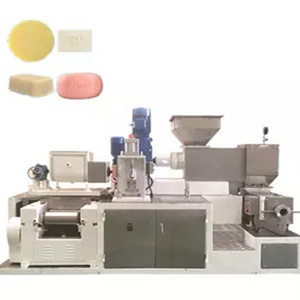

Solid bath soap, laundry soap, round hotel soap, hair soap production line design scheme

For small soap production lines, my company has successfully developed a soap, clear soap process and equipment suitable for home and small and medium-sized investors.

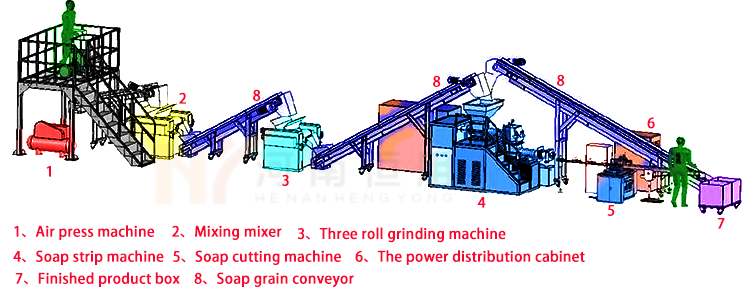

Main equipment: mixing machine, three-roll grinder, vacuum stripping machine, soap printer, conveyor belt, control cabinet.

Equipment features:

1, the machine adopts a single single screw out bar, driven by frequency conversion speed control motor, wide speed control range, can be very good with printing. The outlet is equipped with a temperature-controlled electric heating device to ensure that the soap body has internal strength and good appearance quality.

2, automatic production, high work efficiency;

3, a multi-purpose machine, can produce a variety of soap, laundry soap, transparent soap

Mixing machine

This equipment is 150 type mixer, which is mainly used for mixing saponin in daily chemical production of soap and soap, and can also be used for mixing and mixing semi-powdery and non-dense materials in other chemical industry. The equipment has simple structure and long service life. (Customizable stainless steel)

Functions:

The various raw materials for the production of soap and transparent soap are fully and evenly stirred and mixed to make the soap grains fine, and various auxiliary materials and additives and flavors are completely mixed into the granulation to meet the formula requirements.

The three-roll grinding machine is mainly used for mixing and grinding normal temperature granular blue bubbles, soap and other raw materials. The machine through the horizontal direction is three rollers side by side each other extrusion, and different speed friction to achieve grinding effect, general materials if you need to achieve a more delicate effect, you need to grind 2 to 3 times, grinding fineness of 3~18μm.

The plodder machine is to make those mix and grind the soap pieces, thin strips, soap powder and other soap raw materials into a continuous soap bar for printer printing.

This machine adopts single worm strip shaft, driven by frequency conversion speed regulating motor, wide range of speed regulation, can be well matched with printing. The outlet is provided with electric temperature control Heating device to ensure that the soap has a certain internal strength and good appearance quality.

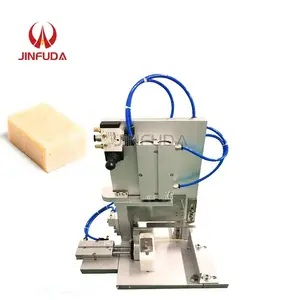

This equipment is suitable for the production of soap, hotel soap, etc., round, oval or shaped soap. According to the drawing or sample custom soap out of a mold to use.

The linear sliding guide rail greatly reduces the friction coefficient between parts and improves the motion accuracy and flexibility.

Features:

low vibration, low noise, high production efficiency, long service life.

Production capacity:The output is the same as that of soap strip machine

Can customize a pair of abrasive tools for customers,Customer's soap logo can be rolled out

The standard model HY-J42 has a production capacity of 0-180 pieces/minute, which can be adjusted by the user according to the production speed of the soap forming machine.

Parts contacting to soap noodle : food grade conveyor belt

Customize the conveyor length according to the machine matching of the production line

Specification

|

Model

|

SDCT-150C

|

|

Capacity(kg/h)

|

150-170kg/h

|

|

Power(kw)

|

20-30kw

|

|

Production line size(m)

|

12.8m

|

|

Soap weight(g)

|

25-750g

|

|

Soap size(mm)

|

Maximum diameter 60mm

|

|

Worm Dia(mm)

|

150mm

|

|

Shaft speed(RPM)

|

2-20

|

|

Power(kw)

|

5.5kw

|

Hot Searches