- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

10 KG

-

Certification:

-

ISO CE

-

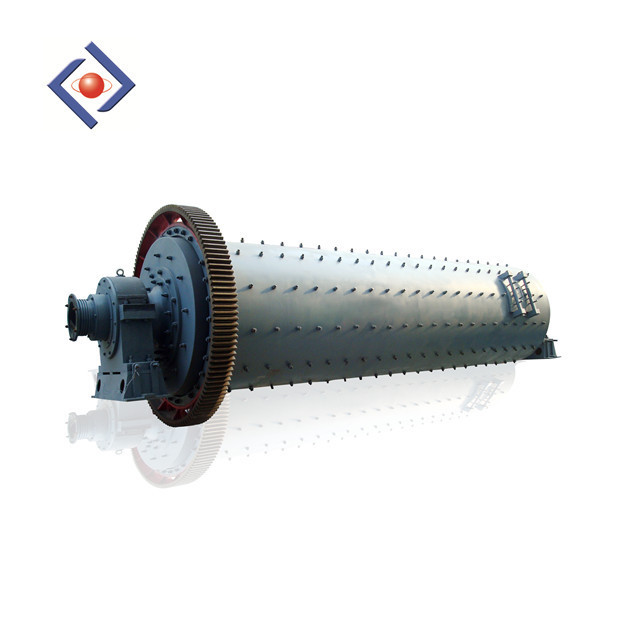

Name:

-

continuous ball mill

-

Application:

-

Minerals

-

Output size:

-

74um-5um

-

Usage:

-

Powder processing

-

Grinding media:

-

grinding balls

-

Feeding Size:

-

Less than 3mm

Quick Details

-

Marketing Type:

-

Hot Product

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

zhengyuan

-

Weight:

-

10 KG

-

Certification:

-

ISO CE

-

Name:

-

continuous ball mill

-

Application:

-

Minerals

-

Output size:

-

74um-5um

-

Usage:

-

Powder processing

-

Grinding media:

-

grinding balls

-

Feeding Size:

-

Less than 3mm

Applications of continuous ball mill:

(1) Soft materials: calcite, marble, limestone, kaoline, gesso, barite, coal ash and slag, etc.

(2) Hard materials: carborundum, brown corundum, superfine cement, zirconium sand, and fire-proof materials, etc.

(3) High purity materials: quartz, feldspar, α-alumina, glass fine bead, etc.

(4) Metal powders: zinc powder, aluminum powder, iron powder, and molybdenum powder, etc.

Features of c

ontinuous ball mill:

1. Low energy consumption: LHM superfine ball mill production line adopted high advanced energy-saving technology and classification technique; as a result, our production line can save over 40% energy for producing same quantity materials.

2. Several times of classification could be obtained:

Finished product fineness after first time classification: 300-2500mesh; if our ball mill production line is equipped with a second classification system, the finished product fineness after second time classification would be 6,250mesh (d97≤2um).

3. Adopted highly advanced self-diffluent classification system:

4. Scientific grinding medium enable us to produce large quantity superfine particles.

5. Different lining boards and grinding mediums are available for milling different materials, so as to guarantee the purity and whiteness of finished products.

6. Scientific machine structure enables a lower investment cost;

7. Low failure rate and stale operation: because our ball mills and classifiers in the production lines are VFC controlled and have high automation;

8. Negative pressure production condition gives a good production environment;

9. High annual production capacity: 5-500 thousand tons.

Note:

We have prepared two sets of ball mill production lines in our factory to do any industrial testing!

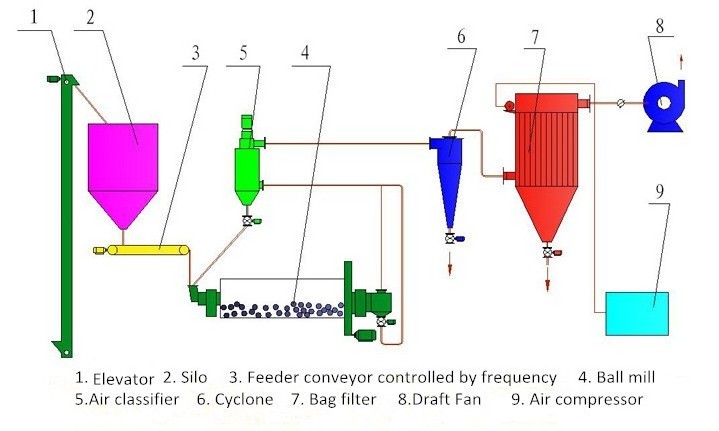

Working Principle of c

ontinuous ball mill:

1. Material feeding.

2. Impact grinding

3. Classification