- Product Details

- {{item.text}}

Quick Details

-

Power:

-

0.74

-

Weight (KG):

-

100 kg

-

Product name:

-

Dissolved air flotation

-

Color:

-

Customized

-

Processing custom:

-

Support

-

Material:

-

SS304

-

Delievery time:

-

After get the deposit within 15 days

-

Brand:

-

hengye

-

Application:

-

Manufacturing Plant

-

Keywords:

-

DAF

-

Function:

-

waste water treatment

-

MOQ:

-

1

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

hengye

-

Size:

-

Customized

-

Power:

-

0.74

-

Weight (KG):

-

100 kg

-

Product name:

-

Dissolved air flotation

-

Color:

-

Customized

-

Processing custom:

-

Support

-

Material:

-

SS304

-

Delievery time:

-

After get the deposit within 15 days

-

Brand:

-

hengye

-

Application:

-

Manufacturing Plant

-

Keywords:

-

DAF

-

Function:

-

waste water treatment

-

MOQ:

-

1

Product Introduction

Dissolved Air Flotation

The working principle and application range of the dissolved air flotation device are basically the same as other air flotation devices, but there are significant structural reforms. It has the following advantages:

Equipment integration:

Generally, air flotation systems are composed of separate air flotation tanks, dosing equipment, gas tanks, gas pumps, air compressors, and sewage pumps. This results in long installation time, inconvenient management, and a large footprint. YF air flotation combines these separate equipment organically, and generally adjusts the pH value of sewage. As long as the inlet and outlet pipes are connected, they can be immediately put into use.

Operation automation:

Once YF air flotation is debugged, it can reach an automated and unmanned management state during normal operation.

Working Principle

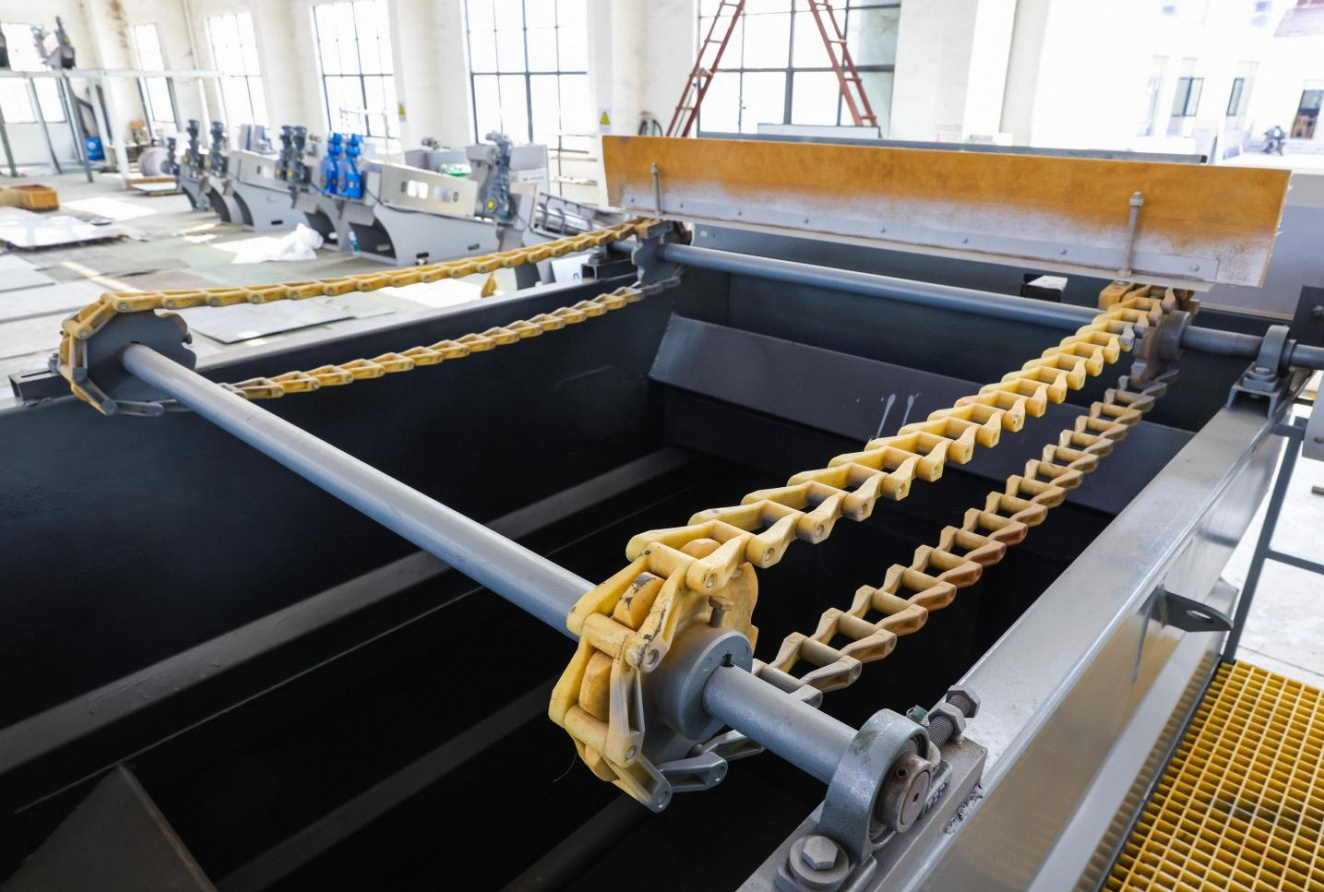

The working method of the equipment belongs to pressurized dissolved gas floatation, its working principle: under certain conditions, a large amount of air is dissolved in water to form dissolved gas water, as the working medium, through the release of sudden decompression, rapid release, produce a large number of fine bubbles. It is adhered to the "alum flower" in the wastewater after coagulation reaction, so that the floc floats upward, and the scum and oil are scraped by the special scraping device to achieve the purpose of solid-liquid separation.

Application Scope

1.Heavy metal ions in electroplating wastewater.

2.The COD removal rate of food slaughtering and tannery wastewater is about 70%,and the removal rate of suspended solids is about 90%.

3.Oil in refining wastewater can be reduced to less than 10 mg/l. Wastewater can reach the degree of clarification for chemical wastewater and pigment paints,COD removal rate of 74%, chroma removal rate About 93 percent.

4.The fiber recovery rate of papermaking white water can reach about 95%, the COD removal rate is about 86.7%,

and the water is completely reused.

and the water is completely reused.

5.The turbidity of the bath water in the large pool can be stabilized below 10 degrees, and the bacteria in the water have a significant decrease. The turbidity of drinking water and industrial water can be purified to less than 5 degrees, and it has a good effect on the reduction of chroma oxygen consumption.

6.The above data are empirical values, for reference only, based on the actual effect.

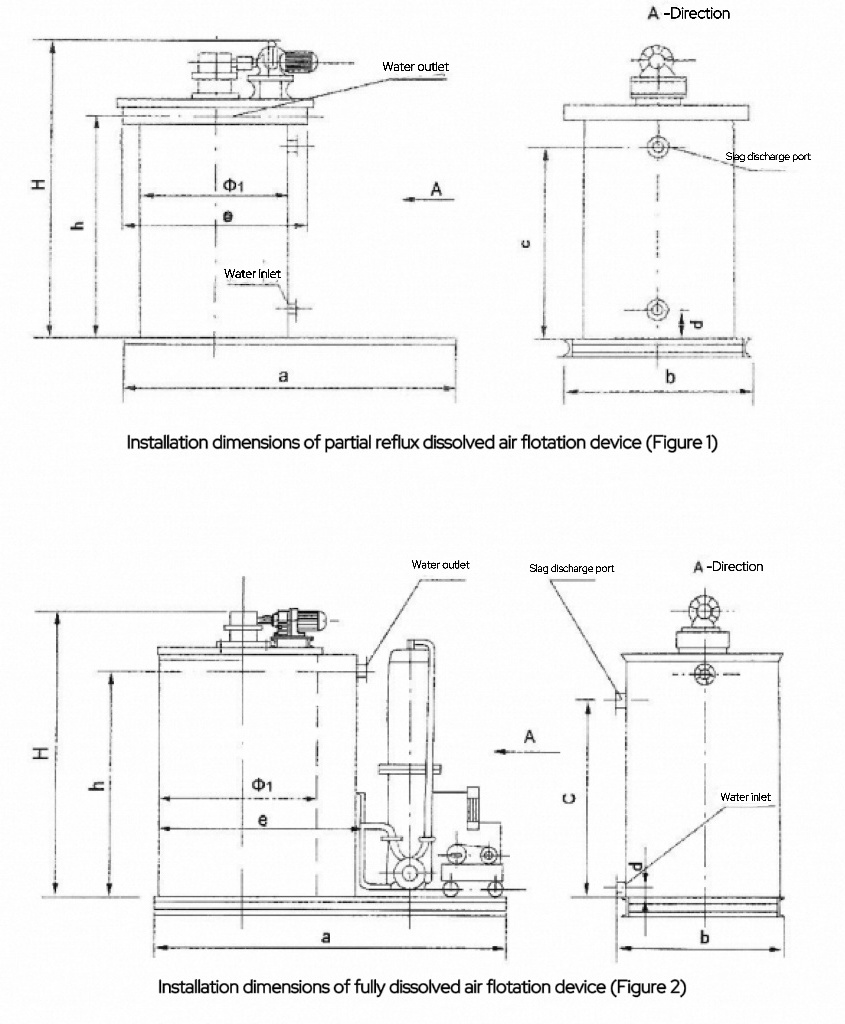

Product Parameters

|

specifications(mm)

|

a

|

b

|

c

|

d

|

H

|

h

|

|

5

|

3000

|

1600

|

1920

|

100

|

2680

|

2280

|

|

10

|

3300

|

1900

|

1920

|

100

|

2680

|

2295

|

|

15

|

3500

|

2500

|

1860

|

100

|

2680

|

2295

|

|

20

|

3800

|

2800

|

1860

|

100

|

2740

|

2310

|

|

25

|

3900

|

3000

|

1830

|

100

|

2740

|

2310

|

|

30

|

4300

|

3000

|

1830

|

100

|

2740

|

2310

|

|

40

|

5200

|

3000

|

1830

|

100

|

3100

|

2310

|

|

50

|

6200

|

3000

|

1830

|

100

|

3100

|

2310

|

|

60

|

7100

|

3000

|

1830

|

100

|

3100

|

2310

|

|

80

|

8600

|

3000

|

1830

|

100

|

3100

|

2310

|

|

100

|

10600

|

3000

|

1830

|

100

|

3100

|

2310

|

|

specifications(mm)

|

Φ1

|

e

|

Diameter

|

|

|

|||||

|

|

|

|

Water Outlet

|

Water Inlet

|

Slag Discharge Port

|

|||||

|

5

|

1500

|

1900

|

150

|

150

|

150

|

|||||

|

10

|

1800

|

2200

|

150

|

200

|

200

|

|||||

|

15

|

2400

|

2800

|

150

|

200

|

200

|

|||||

|

20

|

2700

|

3100

|

200

|

225

|

200

|

|||||

|

25

|

2900

|

3300

|

200

|

225

|

200

|

|||||

|

30

|

3150

|

3550

|

225

|

225

|

200

|

|||||

|

40

|

3200

|

3600

|

250

|

250

|

200

|

|||||

|

50

|

4200

|

4600

|

250

|

250

|

200

|

|||||

|

60

|

5000

|

5400

|

250

|

250

|

200

|

|||||

|

80

|

6600

|

7000

|

300

|

300

|

200

|

|||||

|

100

|

8300

|

8700

|

300

|

300

|

200

|

|||||

|

Remarks:

1. The outlet and slag discharge method is flat method, in accordance with JB/T81-94 standard, p=0.25Pa.

2. The water volume is between 2 specifications The diameter of the air flotation tank can be adjusted Take between two specifications (Φ 1) The values of a and b remain the same for other sizes, e=Φ1+400.

|

|

|

|

|

|

|||||

Other Products

After entering the filter cartridge from the feeding port, the sludge is pushed by the spiral shaft blades and moves towards the

discharge port. The pressure on the sludge also increases continuously, and it is dehydrated under the pressure difference. Water flows out from the filtering gap between the fixed ring and the movable ring. At the same time, relying on the self-cleaning

function between the fixed plate and the movable plate, the sludge cake is fully dehydrated and discharged from the discharge port under the promotion of the spiral shaft.

discharge port. The pressure on the sludge also increases continuously, and it is dehydrated under the pressure difference. Water flows out from the filtering gap between the fixed ring and the movable ring. At the same time, relying on the self-cleaning

function between the fixed plate and the movable plate, the sludge cake is fully dehydrated and discharged from the discharge port under the promotion of the spiral shaft.

Rotary Mechanical Grille

Rotary grid cleaner, also known as rotary solid-liquid separator, is an advanced solid-liquid separation equipment for water treatment. It is mainly used at the inlet of sewage pretreatment devices in urban sewage treatment plants, municipal rainwater and sewage pump stations, water plants, and power plant cooling water

Spiral Conveyor

Spiral conveyor, commonly known as twisted dragon, is a widely used conveying equipment in the mineral, feed, grain and oil, and construction industries. It is made of steel and is used to transport chemical and building materials products such as powders or solid particles with high temperatures.

Customer Testimonial

Hot Searches