- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

4KW/8.5KW

-

Dimension(L*W*H):

-

2.5x1.1x1.72m

-

Weight:

-

2900 kg

-

Product name:

-

Paper Cup Making Machine Automatic

-

Finished Products:

-

Colorful Paper Cup

-

Automation:

-

Fully Atuomatic

-

Raw material:

-

PE Coated Paper

-

Keyword:

-

China Paper Cup Making Machine

-

Type:

-

Paper Cup Producton Line

-

Advantage:

-

High Effiency

-

Speed:

-

50-120 Pcs/min

-

Color:

-

Customized Color

-

Paper Cup Size:

-

2 ~16 OZ (50ml~330ml Mould Exchangeable)

Quick Details

-

Production Capacity:

-

80 pcs/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Young Bamboo

-

Voltage:

-

380V

-

Power:

-

4KW/8.5KW

-

Dimension(L*W*H):

-

2.5x1.1x1.72m

-

Weight:

-

2900 kg

-

Product name:

-

Paper Cup Making Machine Automatic

-

Finished Products:

-

Colorful Paper Cup

-

Automation:

-

Fully Atuomatic

-

Raw material:

-

PE Coated Paper

-

Keyword:

-

China Paper Cup Making Machine

-

Type:

-

Paper Cup Producton Line

-

Advantage:

-

High Effiency

-

Speed:

-

50-120 Pcs/min

-

Color:

-

Customized Color

-

Paper Cup Size:

-

2 ~16 OZ (50ml~330ml Mould Exchangeable)

Products Description

Small manufacturing automatic disposable paper coffee cup forming making machine price with cup printing machine

YB-ZG16 paper cup forming machine use open cam system and single aluminium plate ,which make machine more faster and stably .The machine have plenty of 14 sensors to follow each process .Machine with Automatic double paper feeding system ,ultrasonic ,heating sealing ,oiling,bottom punching,bottom fold,bottom folding,pre-heating ,knurling cup.

Product Paramenters

|

Type

|

YB-ZG2-16

|

|

Cup size

|

2-16oz(different size mold exchanged)

|

|

Suitable paper material

|

Gray bottom white paper

|

|

Capacity

|

50-120pcs/min

|

|

Finished products

|

Hollow/Ripple wall cups

|

|

Paper weight

|

170-400g/m2

|

|

Power source

|

220V 380v 50HZ(please inform us your power in advanced)

|

|

Total power

|

4KW/8.5kw

|

|

Weight

|

1000KG/2500KG

|

|

Package size

|

2100*1250*1750 mm

|

Manufacturing Technique

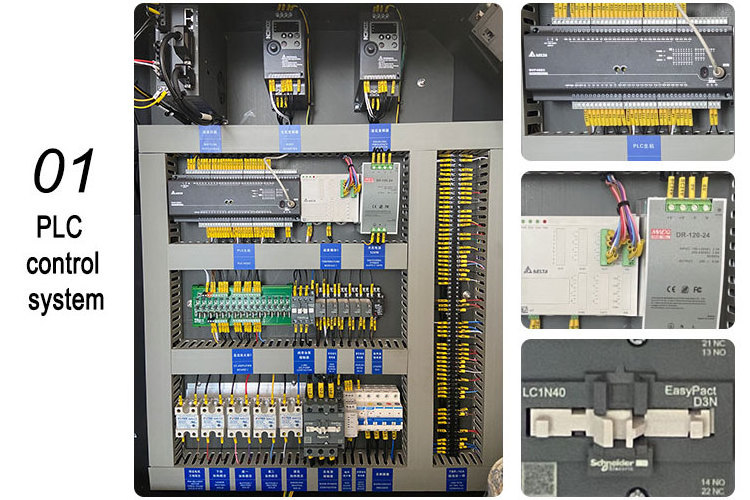

1.PLC control system Brand accessories

2.

Using Delta, Schneider and other high-quality brands, the electrical system control system adopts Delta brand, and the quality is reliable.

The touch screen interacts with the PLC, and all working parameters can be set on the control panel to facilitate parameter setting and adjustment.

The bottom paper feeding is controlled by a servo motor and a stepper motor, which greatly improves the accuracy and efficiency of paper feeding.More stable, less failures, and save base paper

The sensor fault is automatically detected, and the work will be automatically stopped when a fault occurs, which greatly improves safety, and the error message will be displayed on the PLC touch screen.

Advantage

1.Multiple feeding for flat fan paper,multiple mediation ,to avoid unevenness on both sides of fan paper,to avoid the fan paper jam problem.

2.Machine with 14 sensors, to be sure each fan paper run stably in each position ,if any position mistake or failure , machine will start alarm system and stop automatically.

3.Machine use direct feeding system for paper bottom,use servo motor for feeding bottom paper,use automatic sensor to help the pre-feeding ,avoid waste for paper,reduce the bottom down problem during feeding process.

4.Machine with full automatic oil lubrication system ,the oil pump is working continuously during the machine running ,machine is open cam & reducer motor . The above advantages make our LXP-100 machine less failure rate, machine more perfect ,provide better service for all customers.

5.Machine with bottom paper cutting system ,which will make the wasted bottom paper more easy to be recycled.

2.Machine with 14 sensors, to be sure each fan paper run stably in each position ,if any position mistake or failure , machine will start alarm system and stop automatically.

3.Machine use direct feeding system for paper bottom,use servo motor for feeding bottom paper,use automatic sensor to help the pre-feeding ,avoid waste for paper,reduce the bottom down problem during feeding process.

4.Machine with full automatic oil lubrication system ,the oil pump is working continuously during the machine running ,machine is open cam & reducer motor . The above advantages make our LXP-100 machine less failure rate, machine more perfect ,provide better service for all customers.

5.Machine with bottom paper cutting system ,which will make the wasted bottom paper more easy to be recycled.

Details Images

Hot Searches