- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V or as your request

-

Dimension(L*W*H):

-

6000*1870*900mm

-

Weight:

-

600 KG

-

Product name:

-

6S shaking table

-

Application:

-

F77-2

-

Capacity:

-

1 t/h

-

Feeding size:

-

1 t/h

-

Testing:

-

Before delivery

-

Material:

-

Fiberglass

-

Keywords:

-

shaking table

-

Local Service Location:

-

None

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

jinchuan

-

Voltage:

-

380V or as your request

-

Dimension(L*W*H):

-

6000*1870*900mm

-

Weight:

-

600 KG

-

Product name:

-

6S shaking table

-

Application:

-

F77-2

-

Capacity:

-

1 t/h

-

Feeding size:

-

1 t/h

-

Testing:

-

Before delivery

-

Material:

-

Fiberglass

-

Keywords:

-

shaking table

-

Local Service Location:

-

None

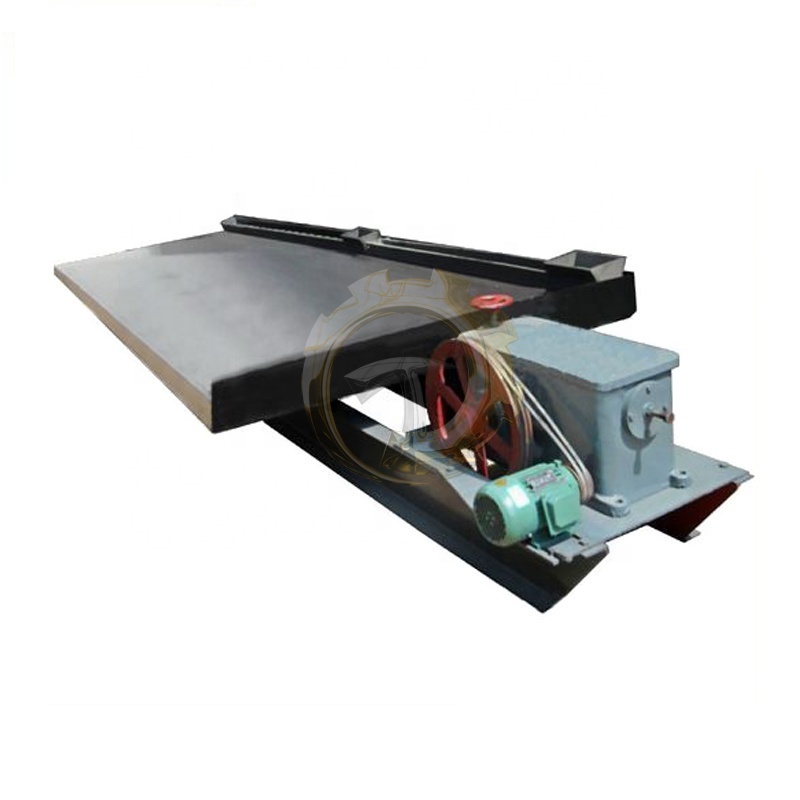

Apply for 6S Shaking Table Gold Shaker table

6S Shaking table which is also called table concentrator, is a mine separation device for fine minerals working by gravity. They are effective in processing precious and base metal, rare metal and non-metallic minerals, widely used in separation for Gold, Silver,Tin, Columbium, Tantalum, Titanium, Barium, Tungsten, Iron, Chrome,Manganese, Zircon, Lead, Zinc, Mercury, Copper, Aluminum, etc. Separating precisely is the prominent advantage of shaking table. We can get some final concentrate, final tailings and 1 or 2 kinds of middling product after the first separating from raw mineral. The enrichment ratio of concentrate is very good, when dealing with low grade tungsten ore and tin ore, the enrichment ratio could reach about 300 times. Besides, the range of separating particle size effectively in dealing with metallic ore is 3 to 0.02 mm.

Gold Shaker table working principle of Shaking Table is to use the combined action of the specific gravity difference of sorted minerals, alternating movement of bed surface, and transverse oblique water flow and riffle (or notch groove),

to allow loose layering of ores on the bed surface and fan-shaped zoning. Then different products can be produced.

Shaking table features:

1.High recovery rate;

2.High concentration rate;

3.Easy installation;

4.Simple operation;

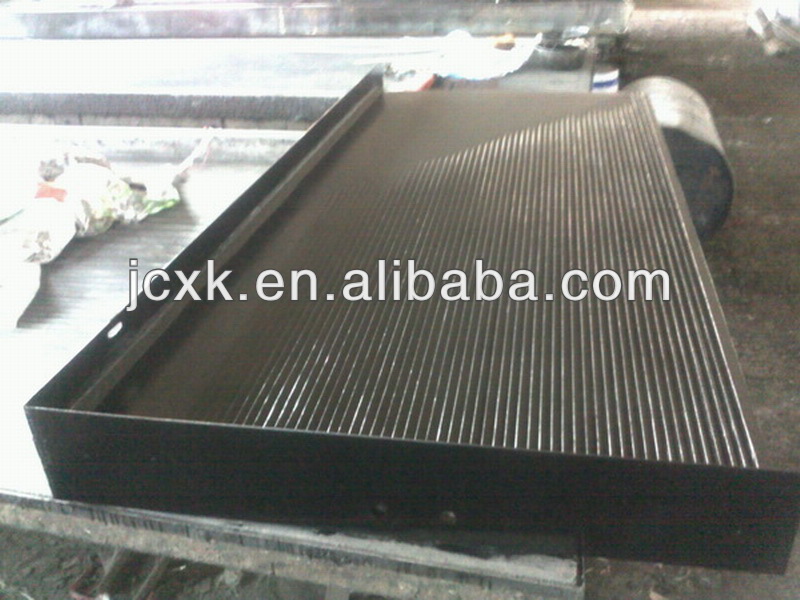

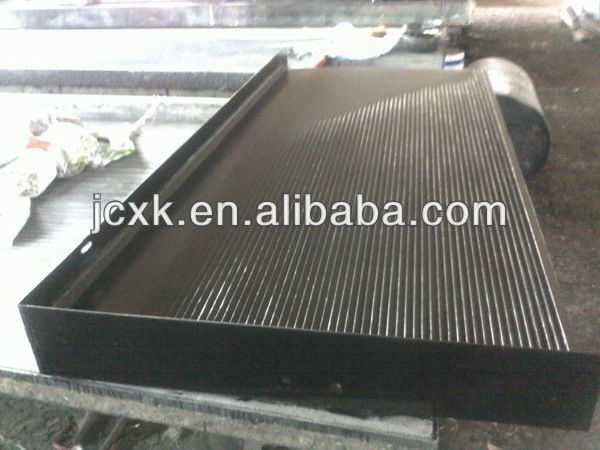

5.Deck constructed of fiberglass;

6.Seven different decks to choose;

7.Long working life;

8.Adjustable stroke length and speed.

| Model(Size) | 450×183×156 | 300×162×110 | 210×105×85 | 110×50×43 | |

| Stroke(mm) | 10-34 | 6—30 | 12—28 | 9—17 | |

| Transverse slope of deck | 0-15 | 0—10 | 0—8 | 0—10 | |

| Feeding size(mm) | Ore | <5 | <2 | <2 | <2 |

| Mud | <1 | <0.074 | < 0.074 | < 0.074 | |

| Feeding density(%) | 10-40 | 10-30 | 10-30 | 10-30 | |

| Capacity(t/h) | Ore | 0.8-1 | 0.7-1.5 | 0.4-0.8 | 0.1-0.2 |

| Mud | 0.5-0.8 | 0.4-1 | 0.3-0.5 | 0.05-0.1 | |

| Water added(t/h) | 1-2 | 0.3-1.5 | 0.2-1 | 0.1-0.5 | |

| motor | power(kw) | 1.1 | 1.1 | 1.1 | 1.1 |

| speed | 1400 | 1400 | 1400 | 1400 | |

| Dimensions(cm) | 600×182×156 | 407×165×80 | 304×105×78 | 153×60×67 | |

| Weight(T) | 0.75 | 0.49 | 0.4 | 0.2 | |

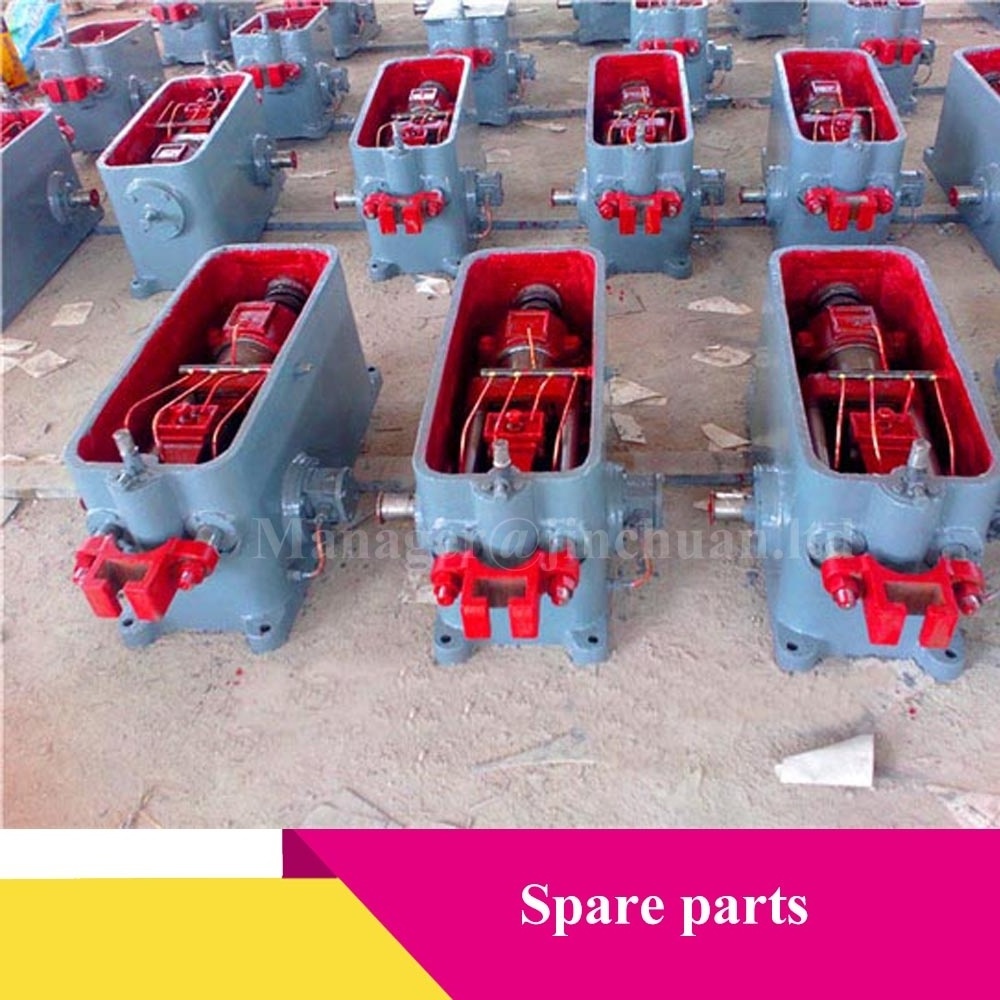

6S shaking table application pictures:

Our distinctive prodcts include shaking table, Jig, Spriral separator, Gold concentrator, Ball mill, Jaw crusher, flotation, magnetic separator, electrostatic separator, vibrating screen, gold pan, feeder, classifier, ore washing machine and lab equipment ect. Our machines are popular in separating GOLD, copper, manganes, chrome, tungsten, tin, nickel, iron, titanium, lead, zinc, tantalum and some non-ferrous metals like quart, zircon, barite,ect.

....