- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

CHINA, MADE IN CHINA

-

Brand Name:

-

XUSHENG & COMPASS

-

Process Combination Form:

-

Single Process, Multi Process, Mixed Process

-

Material Contact Parts:

-

SS316L (1.4404)

-

Material Non-contact Parts:

-

SS304(1.4301)

-

Sealing Material:

-

NBR,EPDM,Silicone,FKM,All material comply with FDA21CFR117.2600

-

Flow:

-

0.1-1000m³/h

-

Exchanger Type:

-

Heating,Cooling,Evaporation,Sterilization and Disinfection

-

One Plate Exchanger Area:

-

0.02m²,0.04m²,0.06m²,0.08m²,0.12m²

-

Plate Thickness:

-

0.7-1.0mm

-

Connection:

-

Union,Tri-clamp, Flange

-

Max. Pressure:

-

10bar (145psi)

Quick Details

-

Type:

-

Heat Exchanger Tube

-

Application:

-

Heater Parts

-

Weight (KG):

-

180

-

Place of Origin:

-

CHINA, MADE IN CHINA

-

Brand Name:

-

XUSHENG & COMPASS

-

Process Combination Form:

-

Single Process, Multi Process, Mixed Process

-

Material Contact Parts:

-

SS316L (1.4404)

-

Material Non-contact Parts:

-

SS304(1.4301)

-

Sealing Material:

-

NBR,EPDM,Silicone,FKM,All material comply with FDA21CFR117.2600

-

Flow:

-

0.1-1000m³/h

-

Exchanger Type:

-

Heating,Cooling,Evaporation,Sterilization and Disinfection

-

One Plate Exchanger Area:

-

0.02m²,0.04m²,0.06m²,0.08m²,0.12m²

-

Plate Thickness:

-

0.7-1.0mm

-

Connection:

-

Union,Tri-clamp, Flange

-

Max. Pressure:

-

10bar (145psi)

Product Description

Compass Plate type heat exchanger is an efficient heat exchanger composed of a series of metal sheets with a certain corrugated shape stacked together. Thin rectangular channels are formed between various plates for heat exchange. Plate heat exchangers are ideal equipment for heat exchange between liquid liquid and liquid vapor. It has the characteristics of high heat exchange efficiency, small heat loss, compact and lightweight structure, small footprint, wide application, and long service life. Under the same pressure loss, its heat transfer coefficient is 3-5 times higher than that of the tubular heat exchanger, its floor area is one-third of that of the tubular heat exchanger, and its heat recovery rate can be up to 90% or more.

Applications:

Our plate type heat exchanger is widely used in food and beverage processing.

1.All kinds of dairy products: Fresh milk, milk powder, milk drinks, Yogurt and so on.

2.Vegetable protein drinks: Peanut milk, milk tea, soy milk, soy milk drinks, etc.

3.Juice drinks: Fresh fruit juice, fruit tea and so on.

4.Cool tea drinks: Tea drinks, reed drinks, fruit and vegetable drinks, etc.

5.Seasoning: Soy sauce, rice vinegar, tomato juice, sweet chili sauce, ect.

6.Breweries: Beer, rice wine, wine and so on.

The plate type heat exchanger is applied to other industrial liquid treatment.

Pharmaceutical, printing and dyeing, heating and heat exchange, chemical, power plant, swimming bath heating, petroleum, metallurgy, hot water, ship, machinery, paper, textile, geothermal utilization, environment protection, refrigeration.

Specification

|

Commodity

|

Plate Type Heat Exchanger

|

|

|

|

|

Detachable Plate Heat Exchanger

(also known as plate heat exchanger with sealing gasket) |

|

|

|

|

Welded Plate Heat Exchanger

|

|

|

|

|

Spiral Plate Heat Exchanger

|

|

|

|

|

Plate Coil Heat Exchanger

(also known as honeycomb heat exchanger) |

|

|

|

Process Combination Form

|

Single Process, Multi Process, Mixed Process

|

|

|

|

Material Contact Parts

|

SS304(1.4301)/SS316L (1.4404)

|

|

|

|

Material Non-contact Parts

|

SS304(1.4301)

|

|

|

|

Sealing Material

|

NBR,EPDM,Silicone,FKM

|

All material comply with FDA21CFR117.2600

|

|

|

Flow

|

0.1-1000m³/h

|

|

|

|

Exchanger Type

|

Heating,Cooling,Evaporation,Sterilization and Disinfection

|

|

|

|

One Plate Exchanger Area

|

0.02m²,0.04m²,0.06m²,0.08m²,0.12m²,0.13Bm²,0.15m²,0.22m²,

0.24m²,0.32m²,0.4m²,0.65m²,0.75m²,0.85m²,1.54m²,1.8m² |

|

|

|

Plate Thickness

|

0.7-1.0mm

|

|

|

|

Connection

|

Union,Tri-clamp, Flange

|

|

|

|

Max. Pressure

|

10bar (145psi)

|

|

|

|

Workingl Pressure

|

0-6bar (0-87psi)

|

|

|

|

Working Temperature

|

14 ~ 302°F (-10ºC~+150 ºC)

|

|

|

|

Sterilization Temperature

|

302°F (150°C)≤30min

|

|

|

|

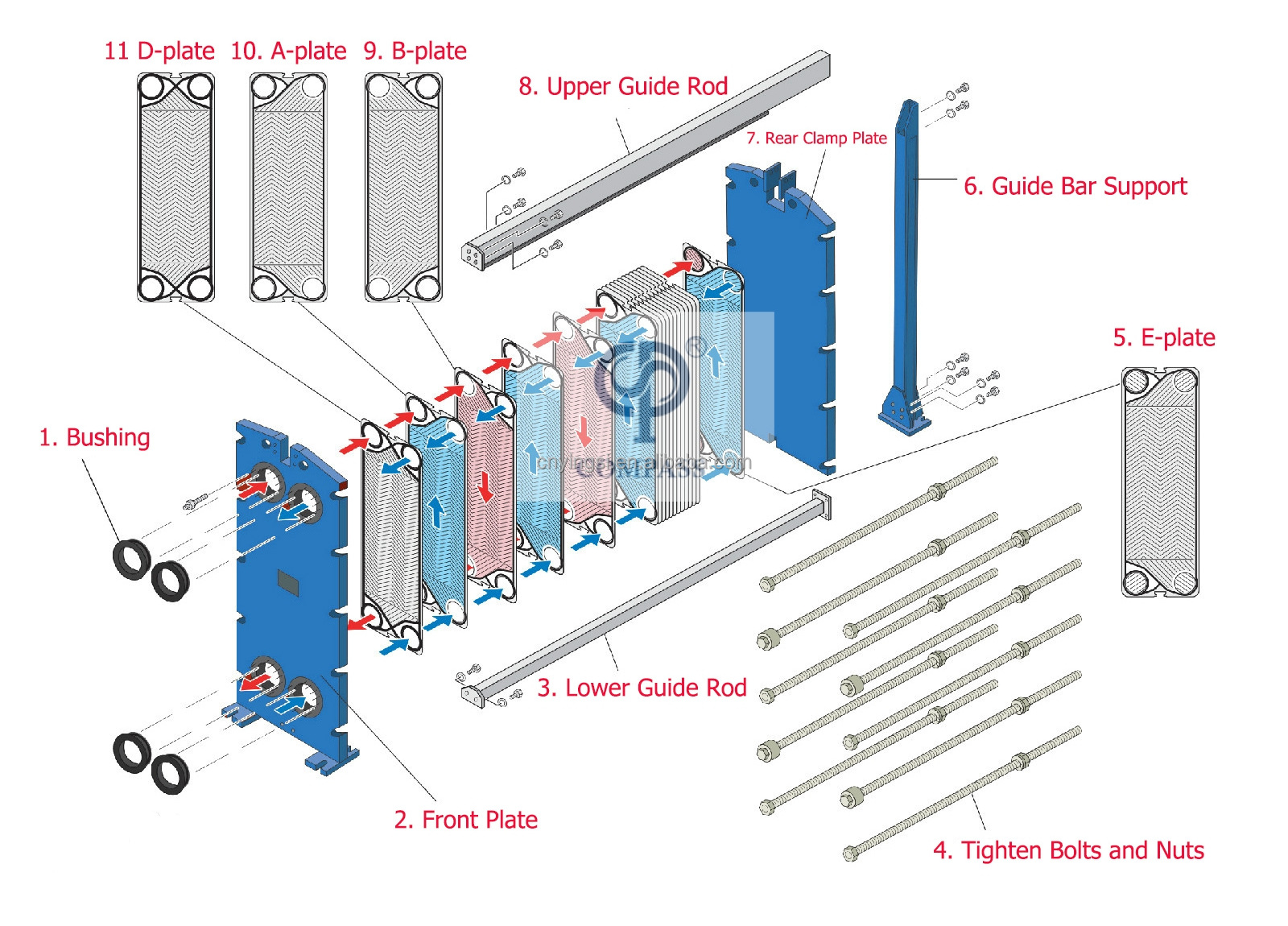

Item

|

Name

|

Item

|

Name

|

|

1

|

Bushing

|

7

|

Rear clamp plate

|

|

2

|

Front Plate

|

8

|

Upper Guide Rod

|

|

3

|

Lower Guide Rod

|

9

|

B Plate

|

|

4

|

Tighten Bolts and Nuts

|

10

|

A Plate

|

|

5

|

E Plate

|

11

|

D Plate

|

|

6

|

Guide Bar Support

|

|

|

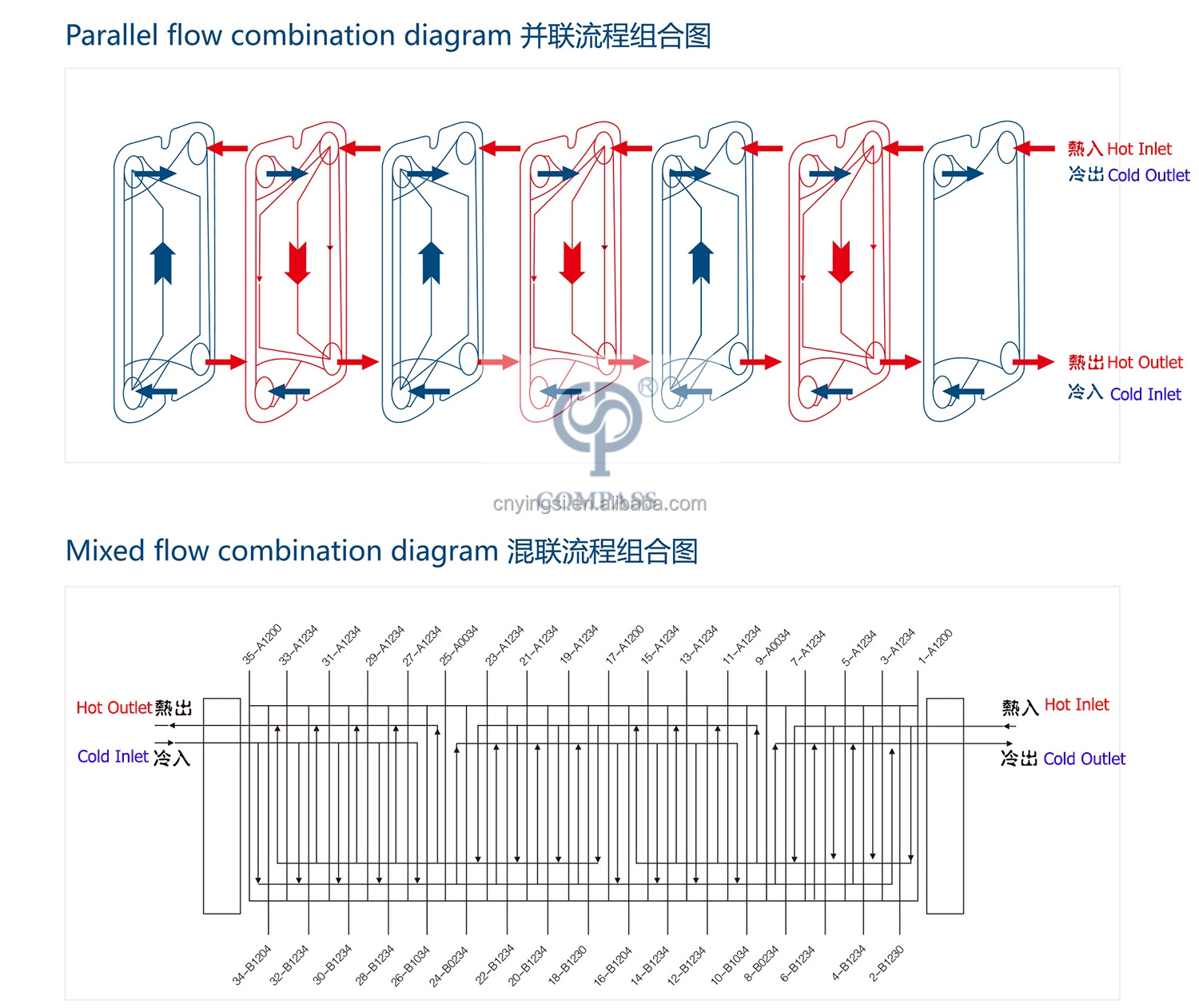

Process Flow of Plate Type Heat Exchanger

1.Because of the special effect of the plate corrugated surface, the fluid flows along the corrugated channel. The velocity direction of the plate heat exchanger changes constantly, which results in the strong end-movement of the fluid at a small flow rate, thus strengthening the heat transfer process. It effectively improve the heat transfer capability and has the outstanding advantages of compact structure, low metal consumption, flexible operation and long service life.

2.The process of heat exchanger is composed of many plates assembled according to a certain process and requirement of the buyer. When assembling, A and B plates are arranged alternately and a network is formed between the plates. The sealing gasket seals the cold and hot media in the heat exchanger. Meanwhile, the cold and hot media are separated reasonably without mixing. Exchanger so as to achieve the desired effect.

3.There are many kinds of flow combinations of plate heat exchanger, which are realized by different reversing plates and different assembly. The process combination can be divided into single process, multi process and mixer process.

|

Model

|

Plate Size(MM)

|

Channel

|

Heat Exchanger Area(M²)

|

Flow

(T/H)

|

Plate Quantity

(PCS)

|

Connection Size

(MM)

|

|

CPS-0.06

|

160*500*0.5

|

Single Channel

|

1

|

0.5

|

17

|

32mm

|

|

CPS-0.06

|

160*500*0.5

|

Double Channel

|

3

|

1.5

|

20+31

|

32mm

|

|

CPS-0.13

|

200*800*0.4

|

Double Channel

|

5

|

2.5

|

15+24

|

38mm

|

|

CPS-0.13

|

200*800*0.4

|

Double Channel

|

7

|

3

|

22+33

|

38mm

|

|

CPS-0.13

|

200*800*0.4

|

Double Channel

|

10

|

5

|

31+46

|

38mm

|

Basic information

each plate contains two parts:

Metal plate:It is an important heat transfer element for pressing metal sheet with corrugation, sealing groove and corner hole. Corrugated not only can strengthen heat transfer, and can increase the sheet and rigid, so as to improve the bearing capacity of the plate heat exchanger, and because turbulence prompted the liquid state, so it can reduce the formation of sediment or dirt, play a role in "self-cleaning".

Sealing gasket: installed in the slots along the perimeter of the plate of the gasket and seal plate between the peripheral, prevent fluid leak outward, and according to the requirements of design, the sealing part of the Angle of hole, the cold and hot liquids according to their respective port flow.

Sealing principle:

The corrugated plate is pasted with sealing gasket, which is designed to double seal structure and has signal hole.When the medium leaks from the first seal, it can leak out from the signal hole, and the problem can be detected and solved as soon as possible, without causing the mixing of the two media.Sealing gasket according to different media and operating temperature to choose different types of rubber.

Packing & Delivery

If small order and choose by express , the items are packed by shrink wrap and secondly carton cases.

If heavy weight of cargos ,which be packed by strongly seaworthy plywooden cases .

In order to protective items , which will be packed by safety and resistance to shock in plywooden cases .

Hot Searches