Qingdao crowns machinery co.,ltd

was located in Huangdao District, the west coast of Qingdao city, Shandong province, China. We

are specialized in rubber and plastic machinery designing,manufacturing and maintenance work.we have been specializing in rubber and plastic machinery and production line for more than 30 years.

- Product Details

- {{item.text}}

Quick Details

-

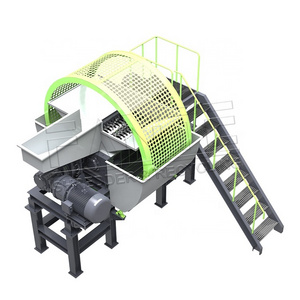

Year:

-

2023

-

Weight (KG):

-

6000 kg

-

Power (kW):

-

2*30

-

Product name:

-

Tire Shredder Machine

-

Raw Material:

-

Waste trye

-

Application:

-

Cut 3-8cm Tyre Rubber Block

-

Tire Processing Range:

-

≤1200 mm Diameter

-

Output:

-

500-800kg/hour

-

Feeding size::

-

1300*500mm

-

Blade material:

-

SKD-II, Cr12mov or D2

-

PKGS:

-

Sea Worthy

Quick Details

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V,50HZ, Customizable

-

Dimension(L*W*H):

-

2800x900x2000mm

-

Year:

-

2023

-

Weight (KG):

-

6000 kg

-

Power (kW):

-

2*30

-

Product name:

-

Tire Shredder Machine

-

Raw Material:

-

Waste trye

-

Application:

-

Cut 3-8cm Tyre Rubber Block

-

Tire Processing Range:

-

≤1200 mm Diameter

-

Output:

-

500-800kg/hour

-

Feeding size::

-

1300*500mm

-

Blade material:

-

SKD-II, Cr12mov or D2

-

PKGS:

-

Sea Worthy

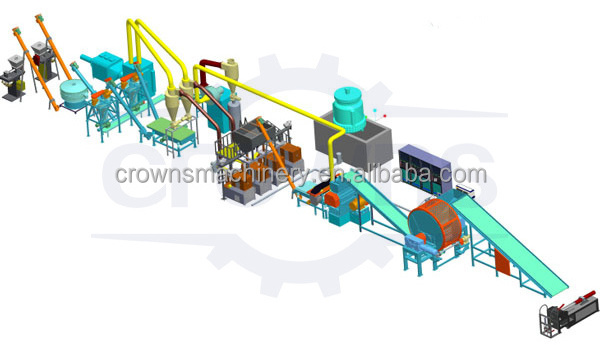

Tire

Shredder Machine/Waste Tire Recycling Line

Introduction

T

ire shredder machine is designed to crush used or waste tires into smaller pieces or shreds

of various sizes

. This machines are used in kinds of industries and applications for recycling purposes, waste management, and sometimes for reducing the size of tires for disposal or transportation.

how does a tire shredder works:

Feeding

: Used tires are loaded into the shredder's hopper or conveyor system, which transports them to the cutting chamber

Cutting and Shredding

: Inside the cutting chamber, the tires are subjected to a combination of sharp blades, rotating drums, or other cutting mechanisms. These mechanisms shred the tires into smaller pieces or strips.

Sizing

: Depending on the specific machine and application, the resulting tire shreds can vary in size. Some tire shredders produce larger chunks, while others produce finer shreds. The size of the shreds can be adjusted by changing the settings on the machine.

|

Model

|

CRDM600

|

CRDM1000

|

CRDM1200

|

CRDM1500

|

CRDM1900

|

CRDM2600

|

|

Motor Power

|

11*2 Kw

|

30*2 Kw

|

45*2 Kw

|

55*2 Kw

|

90*2 Kw

|

160*2 Kw

|

|

Capacity

|

2-6 T/H

|

3-8 T/H

|

5-10 T/H

|

8-18 T/H

|

10-25 T/H

|

25-60 T/H

|

|

Blade Number

|

34 Pieces

|

34 Pieces

|

30 Pieces

|

38 Pieces

|

34 Pieces

|

25 Pieces

|

|

Input Opening Size(mm)

|

950*700

|

1200*1000

|

1500*1200

|

2000*1500

|

2500*2000

|

3000*2500

|

|

Dimension L/W/H(m)

|

2.6*0.9*1.8

|

3.6*1.5*2.2

|

4.6*1.8*2.6

|

5.2*2.0*2.6

|

6.2*2.5*2.8

|

8.2*4.0*4.3

|

|

Weight

|

3T

|

5 T

|

8 T

|

13 T

|

18 T

|

36 T

|

We can also design and produce according to your requirement. If you are interested in our products or have any questions, please don`t hesitate to contact us .

Application

CROWNS MACHINERY

CROWNS MAIN PRODUCTS

* Rubber mixing equipment: kneader mixing machine, bucket,mixing mill, bale cutter

* Rubber vulcanizing machine: Four-column press, Frame press, E-type press,vacuum molding press,injection press, tire and tube press, Belt vulcanizing press.

Rubber calendaring machine: 2 roll, 3 roll, 4 roll calender, calendaring line

Rubber extruding equipment: Hot feed extruder,cold feed extruder, belt extrudingand calendering line

* Rubber ,silicone,plastic products prdocuction line

* Automatic and semi-automatic waste tire recycling equipment

* Used tyre retreading machine line

* Rubber vulcanizing machine: Four-column press, Frame press, E-type press,vacuum molding press,injection press, tire and tube press, Belt vulcanizing press.

Rubber calendaring machine: 2 roll, 3 roll, 4 roll calender, calendaring line

Rubber extruding equipment: Hot feed extruder,cold feed extruder, belt extrudingand calendering line

* Rubber ,silicone,plastic products prdocuction line

* Automatic and semi-automatic waste tire recycling equipment

* Used tyre retreading machine line

Q1: Where is your factory located?

A1: Qingdao crowns machinery co.,ltd is located at Huangdao district ,Qingdao city, China

Q2: Are you an integrated supplier for rubber&plastic machine ?

A2: Yes, we can provide the complete solution line to customer according to customer’s requirement.

Q3: How about the quality control in your factory?

A3: Qingdao crowns has the SOP (Standard Operation Procedure) and all the production step must follow up this SOP. Every machine needs at least automatic running over 72 hours and must be inspected carefully before shipment.

Q4: Will you offer the pre-sales service?

A4: Yes, we have an experienced pre-sales team to support customers not only including machine, technology also water

.electrical,machine layout in factory, etc.

Q5: What about the after-service? Will you send your engineer to my country to help commission and install the machine?

A5: Surely, we have many experience technical engineers for oversea service, they would help you install machine and support training to workers also.

Q6: What is the delivery time of the machine?

A6: Actually, the delivery time of the machines is depended on the machine options. Normally, the delivery time of standard machine could be within 10-30 days

Q7 : What is the warranty of the machine ?

A7: The whole machine’s warranty period is 12 months and key parts will be depended.

Q8 : Do you provide any spare parts with machine?

A8: Yes, CROWNS will provide one set standard spare parts to customer according to different machines

A1: Qingdao crowns machinery co.,ltd is located at Huangdao district ,Qingdao city, China

Q2: Are you an integrated supplier for rubber&plastic machine ?

A2: Yes, we can provide the complete solution line to customer according to customer’s requirement.

Q3: How about the quality control in your factory?

A3: Qingdao crowns has the SOP (Standard Operation Procedure) and all the production step must follow up this SOP. Every machine needs at least automatic running over 72 hours and must be inspected carefully before shipment.

Q4: Will you offer the pre-sales service?

A4: Yes, we have an experienced pre-sales team to support customers not only including machine, technology also water

.electrical,machine layout in factory, etc.

Q5: What about the after-service? Will you send your engineer to my country to help commission and install the machine?

A5: Surely, we have many experience technical engineers for oversea service, they would help you install machine and support training to workers also.

Q6: What is the delivery time of the machine?

A6: Actually, the delivery time of the machines is depended on the machine options. Normally, the delivery time of standard machine could be within 10-30 days

Q7 : What is the warranty of the machine ?

A7: The whole machine’s warranty period is 12 months and key parts will be depended.

Q8 : Do you provide any spare parts with machine?

A8: Yes, CROWNS will provide one set standard spare parts to customer according to different machines

Hot Searches