1.

Automatic Static Pressure Moulding Line with KW technology

2. Automatic Shell Molding casting Line

3. Furan Resin Sand proudction casting Line

4.

Pouring system

5.Sand Preparation

6. Founry Sand Mixer

7.Pneumatic sand moulding machine

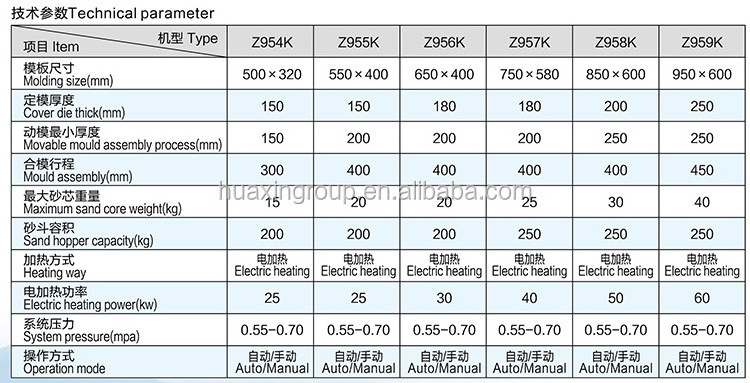

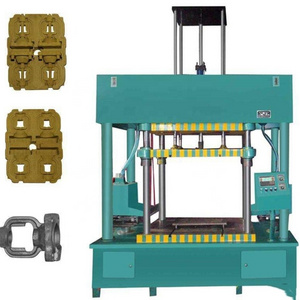

8.Core making machine

9.Shell core machine

10.

Shot blasting machine

11.V process casting line

12.Foam foam casting line