- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

60 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS mach

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

9000*3000*2800mm

-

Power (kW):

-

132

-

Weight:

-

6500kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Area:

-

13*2.4*2.3

-

Total Power:

-

132kw

-

Auxiliary machine:

-

Water-ring

-

Product:

-

Granules

-

Feature:

-

plastic recycling granulating machine

-

Name:

-

PET bottle flakes recycling machine

-

Description:

-

recycling machine

-

AC contactor brand:

-

Siemens brand

-

Main Motor Power:

-

110kw

-

Certification:

-

CE,ISO

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

48:1

-

Screw diameter (mm):

-

71

-

Screw Speed (rpm):

-

60 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS mach

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

9000*3000*2800mm

-

Power (kW):

-

132

-

Weight:

-

6500kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Area:

-

13*2.4*2.3

-

Total Power:

-

132kw

-

Auxiliary machine:

-

Water-ring

-

Product:

-

Granules

-

Feature:

-

plastic recycling granulating machine

-

Name:

-

PET bottle flakes recycling machine

-

Description:

-

recycling machine

-

AC contactor brand:

-

Siemens brand

-

Main Motor Power:

-

110kw

-

Certification:

-

CE,ISO

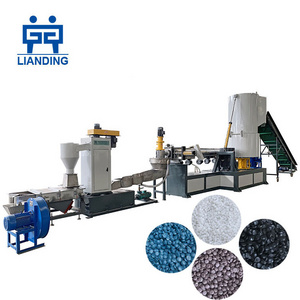

Nanjing GS-mach Full Set PP PE Pet Bottle Flakes Plastic Recycling Granulating Machine

FEATURES AT A GLANCE

Product Overview

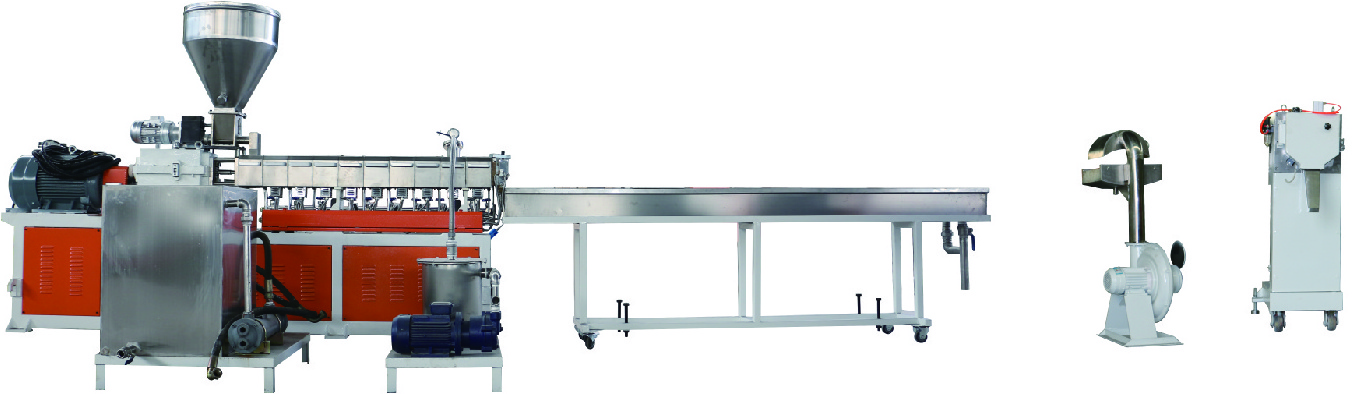

Co-Rotating Twin Screw Extruders

Parallel co-rotating twin screw extruders have excellent mixing performance, good self cleaning performance and flexible modular configuration characteristics which make them suitable for processing different types of material systems, and are extensively used in fields of polymer processing, foodstuff processing and chemical products, especially for various high molecular materials.

In most cases, parallel co-rotating twin screw extruders are used as mixing euqipments. In processing high molecular materials, the modification process and master batch preparation of polyolefin materials and engineering plastics requires sufficient and intensive mixing, which differs depending on material systems, excellent equipment performance, reasonable mixing process, advanced combination technique and rich processing experience are the key factors determining the success and efficiency of mixing.

|

Model Parameter

|

GS-20

|

GS-35

|

GS-50

|

GS-65

|

GS-75

|

GS-95

|

|

Main Motor

|

4

|

45-22

|

37-65

|

45-75

|

75-160

|

132-250

|

|

Screw Diameter

|

21

|

35.6

|

50.5

|

62.4

|

71

|

93

|

|

L/D

|

28-40

|

28-48

|

28-64

|

28-64

|

28-64

|

28-64

|

|

Rotate Speed(rpm)

|

0-600

|

0-600

|

0-600

|

0-600

|

0-600

|

0-600

|

|

Screw Material

|

bi-metal

|

bi-metal

|

bi-metal

|

bi-metal

|

bi-metal

|

bi-metal

|

|

Screw Hardness

|

HRC65

|

HRC65

|

HRC65

|

HRC65

|

HRC65

|

HRC65

|

|

Shaft Core Material

|

40CrNiMoA

|

40CrNiMoA

|

40CrNiMoA

|

40CrNiMoA

|

40CrNiMoA

|

40CrNiMoA

|

Five Regular Types of Pelletizing System.

Water Strand System

.

The material come out from die head and then through water tank for cooling, then there is a pelletizer to cut the material to be granules.

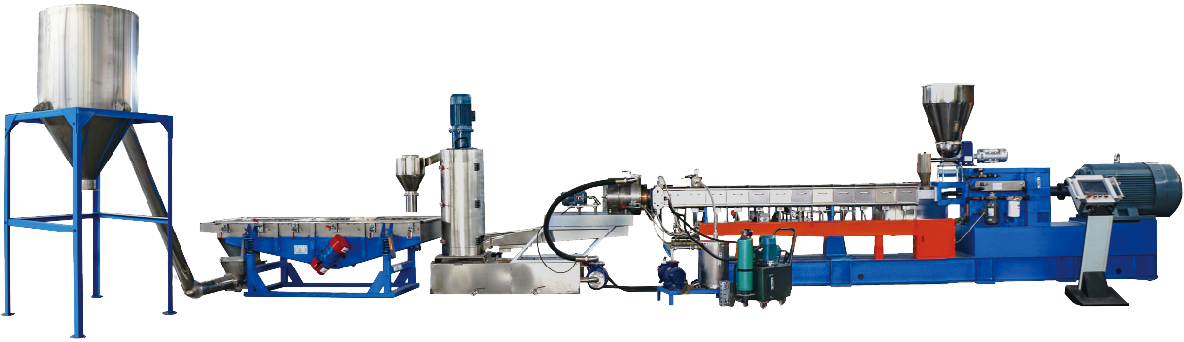

Water Ring System.

The material will be cut in the die head, then drop into the water, through water cooling, then come into the Centrifugal dehydrator, remove the moisture. Then through Vibration sieve and silo.

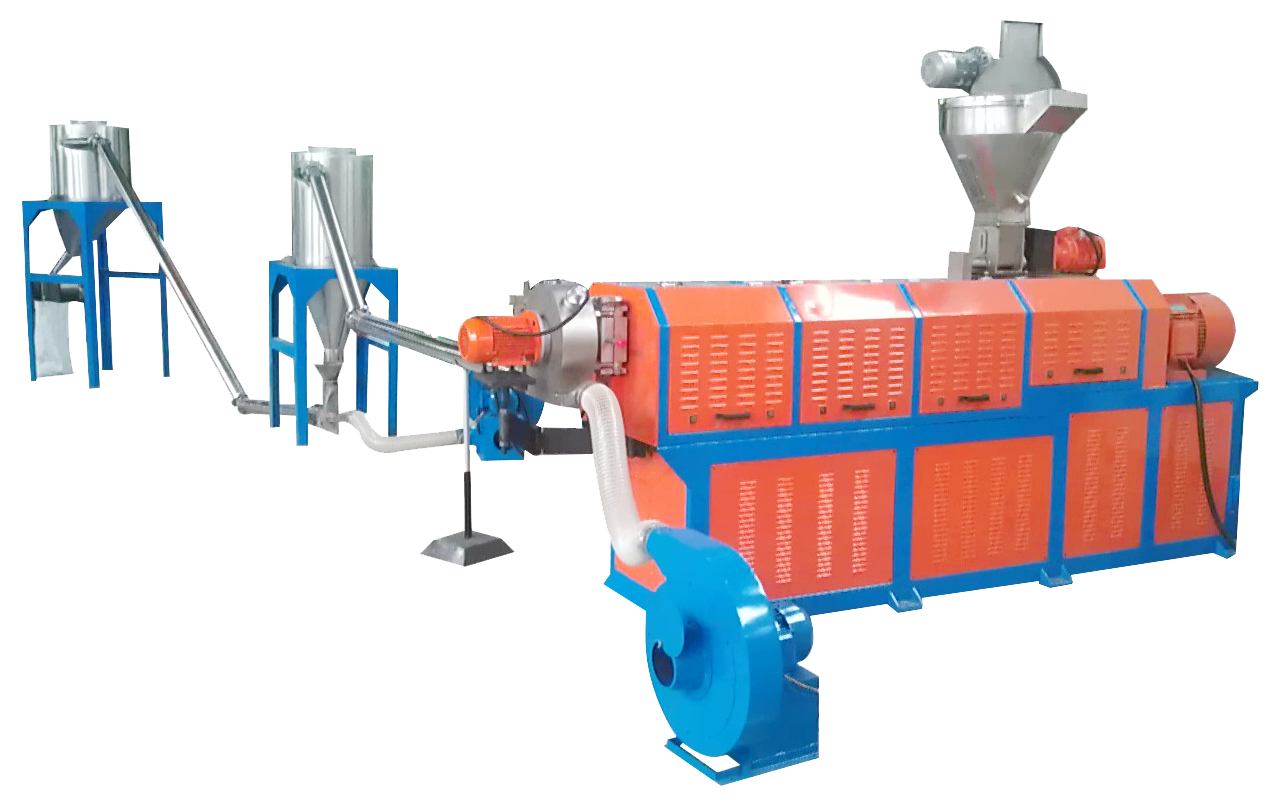

Air Cooling Die Face Hot Cutting System.

The material will be also cut in the die head. Then through cyclone, cooling the material.

Air Cooling Strand System.

The die head is same as water strand die. Then use conveyor belt and cooling fan to cooling the material, then there is a pelletizer to cut the material to be granules.

Underwater pelletizing system.

The die head is under the water, material will be cut in the water and then through Bypass pipe, and drying by the dehydrator.

Related products

Application area

PRODUCT CONFIGURATION

Introduction of Twin Screw

GS-mach is a professional plastic,rubber and chemicals machinery researcher, designer and manufacturer with CE & lSO9001 certificates.

Twin screw extruder is widely used, suit for modification processing and masterbatch production of most plastic materials. Glass-filled reinforcement: PP, PA, PC, ABS, PPS, PET, PBT+glass fibre Compounding and blending: PC+ABS, PA+ABS, PP+EPDM, PP+ SBS Color master batch: PP, PE, PS, PBT, PET, ABS, EVA+color pigment Incorporation of fillers: PP, PA, PC, ABS, PPS, PET, PBT+CaCo3, TALC Compounds for cable and other pelletizing Degassing.

Main production of plastic extruders, plastic particles, degradable plastic production lines, including other plastic machinery production.Chemical raw material formula also has research to sell, so contact us, you will learn more!

Main production of plastic extruders, plastic particles, degradable plastic production lines, including other plastic machinery production.Chemical raw material formula also has research to sell, so contact us, you will learn more!

Hot Searches