- Product Details

- {{item.text}}

Quick Details

-

Mold Height(mm):

-

280 - 750 mm

-

Ejector Stroke(mm):

-

200 mm

-

Ejector Force(kN):

-

125 kN

-

Theoretical Shot Volume(cm³):

-

1759 cm³

-

Injection Rate (g/s):

-

750 g/s

-

Injection Weight (g):

-

1601 g

-

Screw Speed (rpm):

-

166 - 200 rpm

-

Screw diameter (mm):

-

19 mm

-

Screw L/D Ratio:

-

19.7

-

Weight (KG):

-

14700 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

750 mm

-

Model Number:

-

380

-

Brand Name:

-

YUGONG

-

Power (kW):

-

80 kW

-

Product name:

-

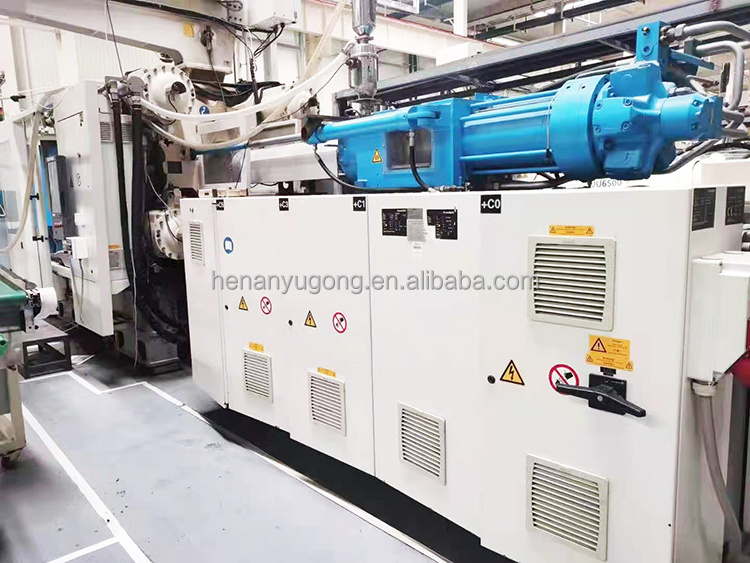

Plastic Injection Moulding Machine

-

Function:

-

Plastic Parts Production

-

Keyword:

-

Used Injection Molding Machine

-

Injection pressure:

-

150Mpa--250Mpa

-

Motor type:

-

HAITIAN Servo Motor

-

Voltage:

-

380V/220/415V

-

Advantage:

-

High Working Efficiency

-

Max.Mold Height:

-

340mm

-

Marketing Type:

-

New Product 2020

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

350mm

-

Distance between Tie Bars(Height)(mm):

-

80mm

-

Plasticizing Capacity(g/s):

-

512

-

Mold Height(mm):

-

280 - 750 mm

-

Ejector Stroke(mm):

-

200 mm

-

Ejector Force(kN):

-

125 kN

-

Theoretical Shot Volume(cm³):

-

1759 cm³

-

Injection Rate (g/s):

-

750 g/s

-

Injection Weight (g):

-

1601 g

-

Screw Speed (rpm):

-

166 - 200 rpm

-

Screw diameter (mm):

-

19 mm

-

Screw L/D Ratio:

-

19.7

-

Weight (KG):

-

14700 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

750 mm

-

Model Number:

-

380

-

Brand Name:

-

YUGONG

-

Power (kW):

-

80 kW

-

Product name:

-

Plastic Injection Moulding Machine

-

Function:

-

Plastic Parts Production

-

Keyword:

-

Used Injection Molding Machine

-

Injection pressure:

-

150Mpa--250Mpa

-

Motor type:

-

HAITIAN Servo Motor

-

Voltage:

-

380V/220/415V

-

Advantage:

-

High Working Efficiency

-

Max.Mold Height:

-

340mm

-

Marketing Type:

-

New Product 2020

Supply all kinds of injection molding machines for the production of plastic products

Our machine is produce all kinds of plastic daily necessities, washbasins, plastic buckets, plastic pallets, garbage cans, plastic tables, plastic chairs, etc. different molds are required for different shapes. We can design them for you

Product Description

Basin Pot Injection Molding -

Injection Unit:

1.) High Quality Linear Motion Guide ensure the smooth & accuracy of injection process

2.) High Speed & Pressure injection structure can improve the injection speed

3.) Twin nozzle cylinder ensures more even & stable structure

4.)

Specialized

screw barrel design for various appliances

Injection Molding Machine -

Clamping Unit:

1.) Optimized Platen Design with high rigidity and enlarged space between tie bars

2.)

Europe-based

Platen Layout with both T-slot & tap holes, locating design in moving platen to better suit various molds

3.) New ejection system design with longer ejection stroke, bigger space and better rigidity

4.) Hydraulic driven gear-type mold height

adjustment

mechanism

5.) Relocation of mechanical safety interlock for easier operation

6.) linkage structure for front connecting rod increases

connecting rods

strength greatly, as well as the whole clamping unit's rigidity & accuracy.

Product Display

Our Company

Hot Searches