- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OCEAN/OEM

-

Voltage:

-

380V

-

Power:

-

5500

-

Dimension(L*W*H):

-

2100*650*650mm

-

Weight:

-

1300 kg, 1300kg

-

Features:

-

extruded and vibrated once to form

-

Name:

-

Lintel making machine

-

Color:

-

Red lintel making machine

-

Type:

-

Semi-automation

-

Capacity:

-

1.2-1.5m/min

-

Products:

-

Floor panels, wall panels,curbstone etc.

-

Function:

-

lintel making machine

-

Advantage:

-

save both time and labour

-

Size:

-

2100*650*650mm

-

Machine Type:

-

building machinery

Quick Details

-

Application:

-

constructional engineering

-

Production Capacity:

-

90m/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

OCEAN/OEM

-

Voltage:

-

380V

-

Power:

-

5500

-

Dimension(L*W*H):

-

2100*650*650mm

-

Weight:

-

1300 kg, 1300kg

-

Features:

-

extruded and vibrated once to form

-

Name:

-

Lintel making machine

-

Color:

-

Red lintel making machine

-

Type:

-

Semi-automation

-

Capacity:

-

1.2-1.5m/min

-

Products:

-

Floor panels, wall panels,curbstone etc.

-

Function:

-

lintel making machine

-

Advantage:

-

save both time and labour

-

Size:

-

2100*650*650mm

-

Machine Type:

-

building machinery

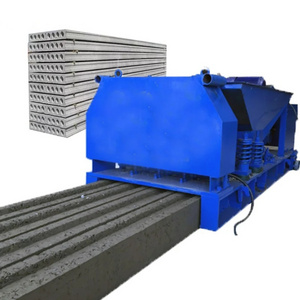

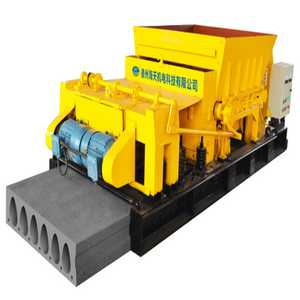

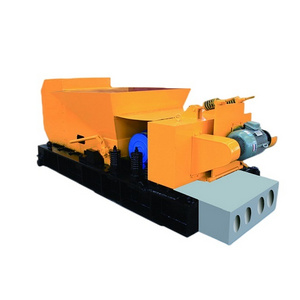

Prestressed precast concrete lintel post pillar beams making machine

It is a special equipment for producing lintel laths and wall piles. It adopts cement, sand and stones to be extruded and vibrated at one time to produce hollow, solid, reinforced and unreinforced concrete pile bodies. Compared with the traditional manual production, the invention has the advantages of good quality, high efficiency, time and manpower can be savde.

1. The improved new type of pushing machine in our factory is 400mm shorter than the old one, saving a lot of steel bars when used.

2. The machine uses the pushing method to make boards, without reamers and floor covering.

3. The edge plate is welded with hard alloy and has a service life of more than two years.

4. High-frequency vibrator and unique rotary material shifting are applied to the areas where fine sand and stone powder are used.

5. The machine-made slab has fast speed, and the produced floor slab is compact and smooth and beautiful.

6.Whether to add holes in the middle and the size of steel plates can be adjusted to support customization.

P arameter

|

Model |

AHQGL500 |

|

Speed |

1.2m-1.5m/min |

|

Power |

5.5kw |

|

Voltage |

380v |

|

Weight |

1300kg |

|

Size(L*W*H) |

2100*650*650mm |

|

Service |

Custom-made |

We need to confirm following information before sent formal offer:

What kind of slab you want to make, wall panel, roof panel, lintel or?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

World Market:

World Market: