- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Depend on you demand

-

Weight:

-

2.4 kg

-

Air volume:

-

6912-322560m3/h

-

Filter bag wind speed:

-

1.0-102m/min

-

Gas consumption:

-

0.27-16.7m3/min

-

Filter area:

-

96-4480 Square meters

-

Heat preservation area:

-

26.5-352 Square meters

-

installation:

-

under our engineer's guide

-

GB/T 24001-2004 idt ISO 14001:2440:

-

passed

-

GB/T 28001-2011, OHSMS 18001:

-

passed

-

overhaul period:

-

10years

-

Lifetime:

-

10-20years

Quick Details

-

Minimum Particle Size:

-

0.5 micron

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

sunsungs

-

Dimension(L*W*H):

-

Depend on you demand

-

Weight:

-

2.4 kg

-

Air volume:

-

6912-322560m3/h

-

Filter bag wind speed:

-

1.0-102m/min

-

Gas consumption:

-

0.27-16.7m3/min

-

Filter area:

-

96-4480 Square meters

-

Heat preservation area:

-

26.5-352 Square meters

-

installation:

-

under our engineer's guide

-

GB/T 24001-2004 idt ISO 14001:2440:

-

passed

-

GB/T 28001-2011, OHSMS 18001:

-

passed

-

overhaul period:

-

10years

-

Lifetime:

-

10-20years

Product introduction

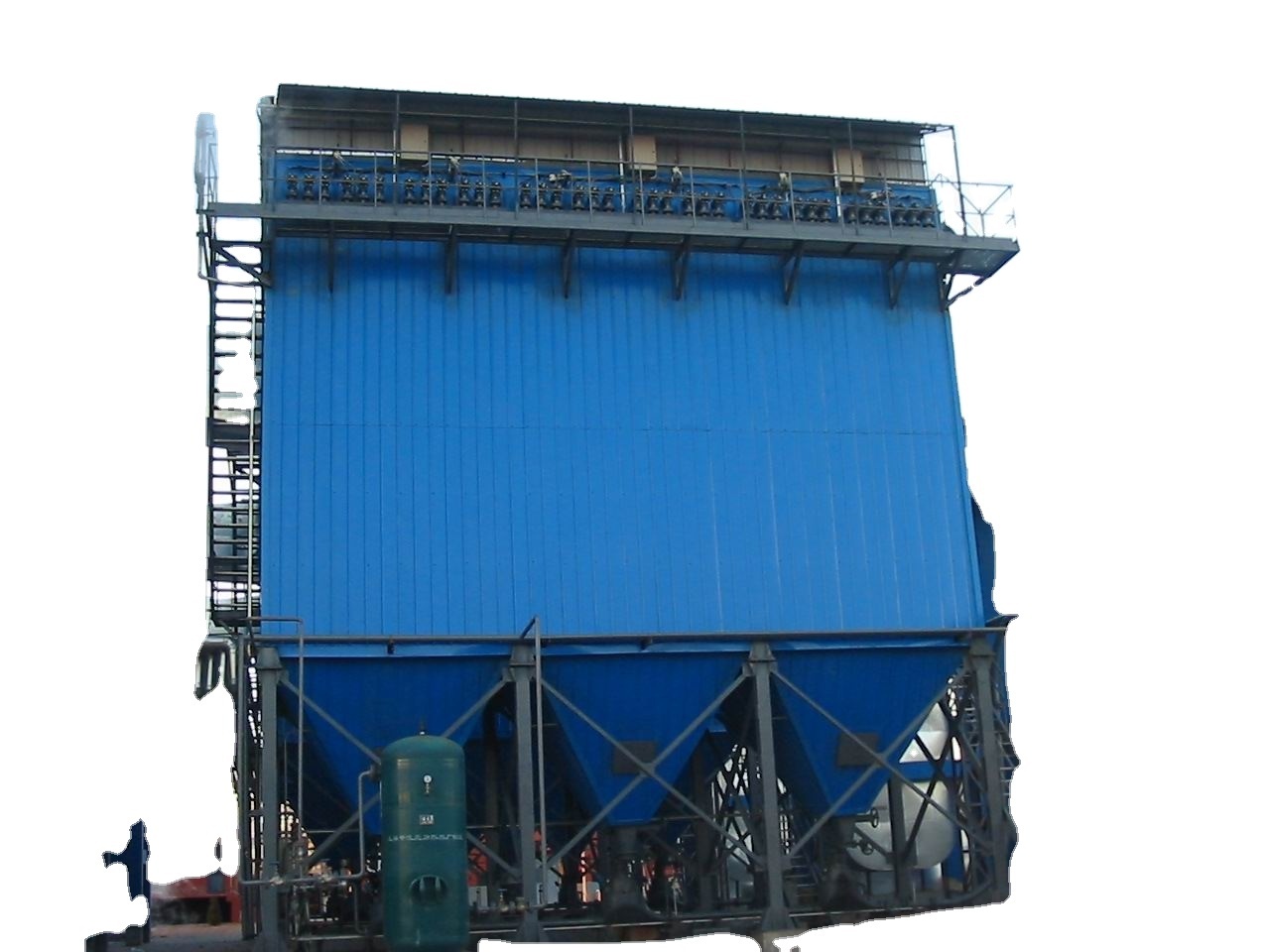

Pulse bag filter dust collector

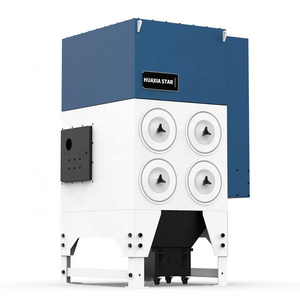

1. Single pulse bag filter:

The stand-alone pulse bag filter can be divided into two types: standard ash bucket type A and open flange type (no ash bucket) B type. Its structure from top to bottom includes: clean air chamber, pulse valve, electronic control system, Drainage device, compressed air bag, dust removal chamber, ash bucket, ash discharge valve, etc.

We design and produce single bag dust collectors. The box body is fully welded and the maintenance door is sealed with rubber strips to ensure the airtightness and waterproof effect of the dust collector. In the long-term practice process, we have continuously improved the design, the equipment structure is more reasonable, and the applicability is stronger. It can complete the filtration and purification of dust gas under various complicated working conditions, with stable operation and high dust removal efficiency. long lasting.

2. Chamber pulse bag filter :

The chamber pulse bag filter is a new type of high-efficiency dust collector improved on the basis of the international MC-II and PPC air box pulse dust collector . The dust collector is designed from the perspective of practical use, which overcomes the insufficient dust removal strength and uneven gas distribution of the chamber air box pulse dust collector, and flexibly adopts the chamber spray and row spray modes, expanding the application range.

The compartment pulse bag filter designed and produced by us is a large-scale offline low-pressure pulse bag dust collector. It can flexibly design the structure and configuration according to the site working conditions, dust characteristics and emission requirements. Manage demand and achieve environmental protection standards.

Performance characteristics

1. Single pulse bag filter:

1.All-in-one model, compact structure, small footprint;

2. Wide range of applications, widely used in power, metallurgy, building materials, chemical, food, tobacco and other industries;

3. The equipment automatically controls the spraying and cleaning of ash, and can also add automatic conveying and unloading devices according to needs, saving manual operation costs;

2. Chamber pulse bag filter :

1. Flexible structure design, tailor-made, strong practicability and wide range of use;

2. Equal-flow flue system, large amount of dust treatment, good dust removal effect; 3. The off-line pulse spraying of ash removal in separate chambers has good dust collection effect and long service life of filter bags;

4. The equipment adopts PLC control, high degree of automation, stable operation and convenient maintenance;

5. Diverse configuration, more suitable for the treatment of dust gas under large air volume and complicated working conditions.

Want to know more, contact me!

The main technical parameters

| Model |

Air volume

(m³/h) |

Filter bag

wind speed (m²) |

Filter area

(m²) |

Number of filter bag

(set) |

Gas consumption

(m³/min) |

Equipment

resistance (pa) |

Dust collecting efficiency

(%) |

Heat preservation area

(m²) |

weight

(t) |

| 32—3 | 6912 | 1.0—1.2 | 96 | 96 | 0.27 | 99.8 | 26.5 | 2.40 | |

| 32—4 | 9216 | 128 | 128 | 0.37 | 34 | 3.40 | |||

| 32—5 | 11520 | 160 | 160 | 0.48 | 41 | 4.40 | |||

| 32—6 | 13824 | 192 | 192 | 0.55 | 48.5 | 5.40 | |||

| 64—4 | 18432 | 256 | 256 | 1.20 | 70 | 8.90 | |||

| 64—5 | 23040 | 320 | 320 | 1.50 | 94 | 10.80 | |||

| 64—6 | 27648 | 384 | 384 | 1.80 | 118 | 11.70 | |||

| 64—7 | 32256 | 448 | 448 | 2.10 | 142 | 13.80 | |||

| 64—8 | 36864 | 512 | 512 | 2.40 | 166 | 14.50 | |||

| 96—4 | 27648 | 384 | 384 | 1.20 | 110 | 11.70 | |||

| 96—5 | 34560 | 480 | 480 | 1.50 | 120 | 13.80 | |||

| 96—6 | 41472 | 576 | 576 | 1.80 | 130 | 15.50 | |||

| 96—7 | 48384 | 672 | 672 | 2.40 | 140 | 17.20 | |||

| 96—8 | 55296 | 768 | 786 | 2.40 | 150 | 20.20 | |||

| 96—9 | 62208 | 864 | 864 | 270.00 | 160 | 21.60 | |||

| 92—2*5 | 69120 | 960 | 960 | 3.00 | 175 | 21.00 | |||

| 92—2*6 | 82944 | 1152 | 1152 | 3.40 | 210 | 25.20 | |||

| 92—2*7 | 96768 | 1344 | 1344 | 4.20 | 245 | 29.40 | |||

| 92—2*8 | 110592 | 1536 | 1536 | 4.80 | 280 | 33.60 | |||

| 92—2*9 | 124416 | 1728 | 1728 | 5.40 | 315 | 37.80 | |||

| 92—2*10 | 138240 | 1920 | 1920 | 6.00 | 350 | 42.00 | |||

| 128—6 | 69120 | 960 | 768 | 3.60 | 125 | 20.10 | |||

| 128—9 | 103680 | 1440 | 1152 | 5.40 | 196 | 26.40 | |||

| 128—10 | 115200 | 1600 | 1280 | 6.00 | 205 | 28.90 | |||

| 128—2*6 | 138240 | 1920 | 1536 | 7.00 | 232 | 36.60 | |||

| 128—2*7 | 161280 | 2240 | 1792 | 8.30 | 247 | 43.90 | |||

| 128—2*8 | 184320 | 2560 | 2048 | 9.50 | 262 | 50.00 | |||

| 128—2*9 | 207360 | 2800 | 2304 | 10.70 | 277 | 55.40 | |||

| 128—2*10 | 230400 | 3200 | 2506 | 12.00 | 292 | 60.00 | |||

| 128—2*11 | 253440 | 3520 | 2816 | 13.40 | 307 | 65.40 | |||

| 128—2*12 | 276480 | 3840 | 3072 | 14.30 | 322 | 72.00 | |||

| 128—2*13 | 299520 | 4160 | 3328 | 15.50 | 337 | 78.00 | |||

| 128—2*14 | 322560 | 4480 | 3584 | 16.70 | 352 | 84.00 |

Want to know more details to contact me!

Application field

PPC air box pulse bag filter series can be widely used in metallurgy, mining, power, materials building machinery manufacturing, food processing, chemical industry, boiler, cement crushing, packaging, library, clinker cooling machine and all kinds of grinding machine, etc. When it used in the coal mill dust, flameproof explosion-proof measures should be added.

product drawing

Contact me for the best offer!