To mix the raw materials evenly, fast speed, no leakage.

Type: Vertical and horizontal type

Motor: 3kw, 4kw, 7.5kw etc.

Material: stainless steel, carbon steel

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

8500 KG

-

Place of Origin:

-

China

-

Voltage:

-

380V/50HZ

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

tasty mouth:

-

delicious

-

Raw materials:

-

Stainless steel

-

product name:

-

Delicious Corn Cheese Puff Snacks Food Processing Extruder Machinery

-

Warranty:

-

One Year

-

Payments terms:

-

L/C ,T/T ,Flexible

-

Shapes:

-

Flower,Stick,Ball,rings,round,curls,and so on

-

Application:

-

cheese puff snack food making equipment

Quick Details

-

Machinery Capacity:

-

150kgh

-

Brand Name:

-

SBN

-

Dimension(L*W*H):

-

24mx2mx4m

-

Weight:

-

8500 KG

-

Place of Origin:

-

China

-

Voltage:

-

380V/50HZ

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

tasty mouth:

-

delicious

-

Raw materials:

-

Stainless steel

-

product name:

-

Delicious Corn Cheese Puff Snacks Food Processing Extruder Machinery

-

Warranty:

-

One Year

-

Payments terms:

-

L/C ,T/T ,Flexible

-

Shapes:

-

Flower,Stick,Ball,rings,round,curls,and so on

-

Application:

-

cheese puff snack food making equipment

Product Description

Fully automatic puffed choco ball manufacturing machine

adopt corn, rice, wheat, oat, barley etc as ingredients to make puffed snack. Through frication of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter. The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

Sample

Parameters

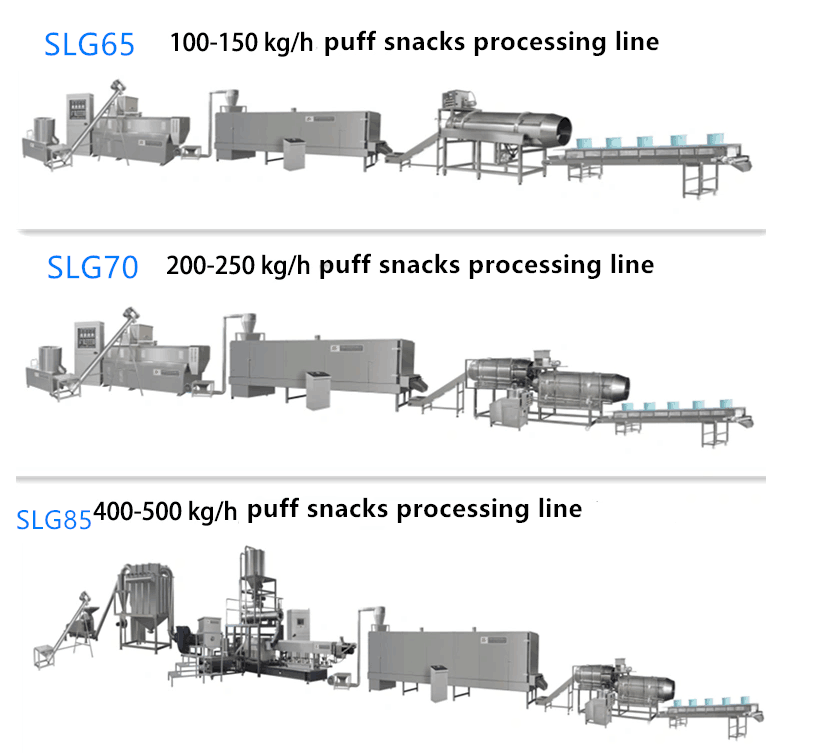

|

Model

|

Installed power

|

Power consumption

|

Output

|

Size

|

|

SLG65 processing line

|

150kw

|

110kw

|

100-150kg/h

|

20000*1200*2200mm

|

|

SLG70 processing line

|

160kw

|

120kw

|

200-250kg/h

|

23000*1500*2200mm

|

|

SLG85 processing line

|

190kw

|

140kw

|

450-500kg/h

|

25000*3500*40000mm

|

Equipment List

Mixer

Extruder

To extrude the raw materials and make them to the required shape and size of the puff snacks food by mould.

Model: SLG65, 70, 85

Model: SLG65, 70, 85

Capacity: 100kg/h to 500kg/h

Material: Screw materials 38CrMoAlstainless steel, carbon steel

Oven

Baking puff snacks food.

Type: electrical, steam, gas fired, diesel fired heating type

Model: KX-3-5, KX-5-5, KX-5-8, KX-5-10, KX-7-10

Capacity: 100kg/h to 10 ton/h

Material: stainless steel, carbon steel

Model: KX-3-5, KX-5-5, KX-5-8, KX-5-10, KX-7-10

Capacity: 100kg/h to 10 ton/h

Material: stainless steel, carbon steel

Flavoring roller

To mix the oil and flavors on the surface of the snacks food.

Type: single and double flavoring drum

Motor: 0.75kw

Capacity: 100kg/h to 500 kg/h

Material: stainless steel

Type: single and double flavoring drum

Motor: 0.75kw

Capacity: 100kg/h to 500 kg/h

Material: stainless steel

Cooling conveyor

To cool and transport the finished food.

Material: stainless steel

Complete processing line in our factory

Company Introduction

Quality Inspection

After Sales Service

1) Provide factory layout according to your factory size in advance;

2) Provide the basic formula;

3) Inspect the machine before leaving the factory; Oversea installation and commissioning equipment;

4) Technician will work with your workers together and teach your workers how to install machines, how to operate machines, how to maintain machines during daily working;

5) Our engineers will teach your workers how to clean the extruder, how to change the screw, how to change barrel etc, and provide technology support with you forever.

FAQ

Q1: Could we visit your factory to check the machine carefully and closely?

A: You’re more than welcome to visit Saibainuo, will provide machine test running, face to face discussion and turnkey project design solution.

Q2. Could you afford technician team to guide our installation and commissioning?

A: Oversea commissioning service provided, our technician will help to install the machine, and teach local workers about operation and maintenance. Buyer should pay for the technician's round flight ticket, accommodation and salary.

Q3. How long is your machine's guarantee time?

A: One year since the machine arrive your factory.

Q4. If some parts break after warranty, what should we do?

A: Saibainuo supply full-life after sales service, whenever new parts needed, we will help to supply new ones at reasonable price & in shortest time.

Q5. If we show our workshop size, can you design layout for the whole line?

A: Auto CAD layout will be provided as client’s workshop size.

Q6. What is the material of the machine?

A: Stainless steel, especially parts contacting with materials, conforming to food grade.

Hot Searches