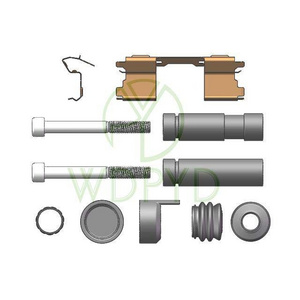

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China, Guangdong, China (Mainland)

-

Brand Name:

-

OEM

-

Model Number:

-

SX-05

-

Name:

-

Bleed Screw

-

Material Used:

-

C1018 Cold Rolled Steel,Stainless Steel,brass,copper,etc.

-

Material Finish:

-

Zinc Trivalent Chromate or customized

-

Standards Met:

-

Customer supplied print

-

Certificate:

-

ISO9001,IATF16949,ROHS

-

Head type:

-

Customized

-

Grade:

-

8.8,12.5,etc

Quick Details

-

Finish:

-

Black, ZINC, Plain, Black Oxide, ZINC PLATED, BLUE DYED, Cadmium Plated, Zinc-aluminum Coated, Chrome Plated, Zinc-Flake Coated, Silver Plated, Blue Anodized, nickel plating,customized

-

Material:

-

Brass, Steel, Aluminium, Plastic, Titanium, NICKEL, Bronze, Nylon

-

Measurement system:

-

INCH, Metric

-

Place of Origin:

-

Guangdong, China, Guangdong, China (Mainland)

-

Brand Name:

-

OEM

-

Model Number:

-

SX-05

-

Name:

-

Bleed Screw

-

Material Used:

-

C1018 Cold Rolled Steel,Stainless Steel,brass,copper,etc.

-

Material Finish:

-

Zinc Trivalent Chromate or customized

-

Standards Met:

-

Customer supplied print

-

Certificate:

-

ISO9001,IATF16949,ROHS

-

Head type:

-

Customized

-

Grade:

-

8.8,12.5,etc

Product Description

|

Product Name

|

Custom Brass Coolant Expansion brake bleed screw For Car

|

|

Material

|

Stainless steel : 303, 304, 316, 412,201,202 etc

Steel: Carbon steel/ die steel, C.R.S etc Aluminum alloy: 6061, 6063, 5052, 2017, 7075,etc Brass alloy:3602, 2604, H59, H62, copper,phosphor bronze,etc Plastic:Nylon,PP,POM,etc Other materials are available |

|

SURFACE TREATMENT

|

Anodizing

, Polishing, Powder coating, Passivation, Sandblasting, Nickal plating,Zinc plating, Chrome plating, Heat treatment, Oxidation

,laser engraved logo

.

|

|

Produce Progresses

|

CNCTurning ,CNC Milling ,CNC Lathe etc.

|

|

EQUIPMETS

|

CNC punching machines, CNC milling machines, CNC turning machines,CNC machining center, Automatic lathes, Linear cutting, Grinding machine etc.

|

|

APPLOCATION

|

Electronic, auto, electric appliance, electrical machine, toy, medical treatment spare metal parts,loudspeaker box, furniture and fitness equipment and other industries.

|

|

MAIN MARKETS

|

U.S.A, UK, Spain, Germany, Italy, Switzerland, etc

|

|

FACTORY OR TRADE COMPANY

|

We are a manufacturing factory.

|

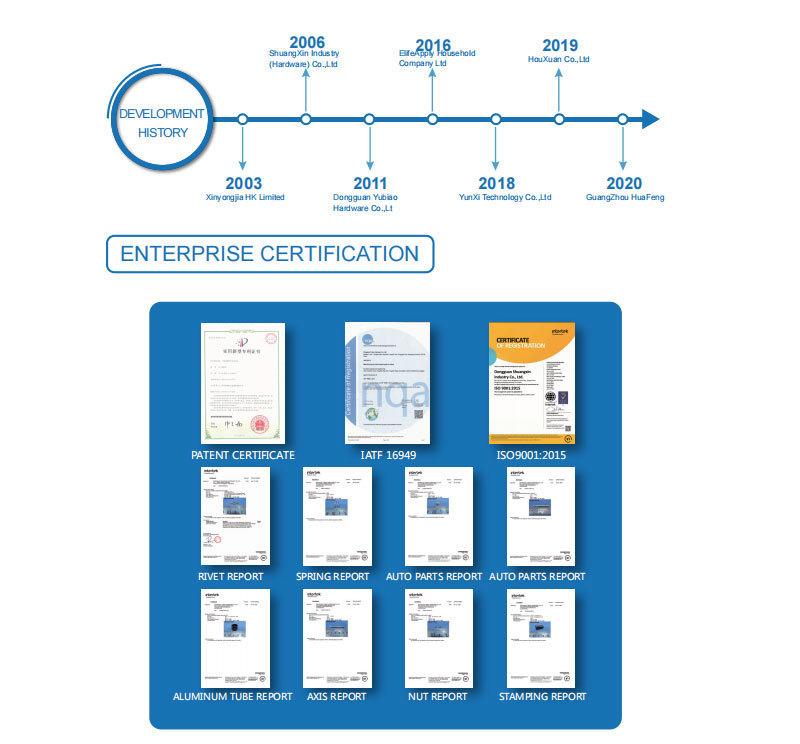

Our Company

Our company founded in October 2000 who is professional to do all kinds of hardware accessorie manufacturers,industry involving toys,electronics,furniture,auto parts and other industries.

Our company has maintained a quality first,reputation

fiirst,inexpensive,andmutually beneficial business purposes.In recent years ,new and old customers trust and support of the company is performance is growing,we know that our achievements and development from each customer is understanding and support of friends.We believe that in the coming years,the company is customers and all frends will continue to grow,our technology will continue to improve.We hope that through our servise,create more and better value for our customers and friends in the newer and higher level.

The employees in our factory,150 to 200 workers.

fiirst,inexpensive,andmutually beneficial business purposes.In recent years ,new and old customers trust and support of the company is performance is growing,we know that our achievements and development from each customer is understanding and support of friends.We believe that in the coming years,the company is customers and all frends will continue to grow,our technology will continue to improve.We hope that through our servise,create more and better value for our customers and friends in the newer and higher level.

The employees in our factory,150 to 200 workers.

Workshop

Other Products

Quality inspection

Packaging & Shipping

Customer praise

FAQ

1.Are you a manufacturer or a trading company?

We are a 3000-square-meter factory located in Shenzhen, China.

2.How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

3. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

4.Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

5. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

6. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

7. How do you control the quality?

(1)Material inspection--Check the material surface and roughly dimension.

(2)Production first inspection--To ensure the critical dimension in mass production.

(3)Sampling inspection--Check the quality before sending to the warehouse.

(4)Pre-shipment inspection--100% inspected by QC assistants before shipment.

8. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

We are a 3000-square-meter factory located in Shenzhen, China.

2.How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

3. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

4.Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

5. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

6. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

7. How do you control the quality?

(1)Material inspection--Check the material surface and roughly dimension.

(2)Production first inspection--To ensure the critical dimension in mass production.

(3)Sampling inspection--Check the quality before sending to the warehouse.

(4)Pre-shipment inspection--100% inspected by QC assistants before shipment.

8. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

Hot Searches