- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SEVENSTARS

-

Voltage:

-

Country Voltage

-

Dimension(L*W*H):

-

8900*1550*1150

-

Power (kW):

-

85

-

Weight:

-

4500 KG

-

Usage:

-

Water pipe, conduit pope and so on

-

Raw material:

-

PVC Powder+additatives

-

pvc pipe plastic machine factory:

-

pvc pipe plastic machine factory

-

PVC pipe workshop:

-

PVC pipe workshop

-

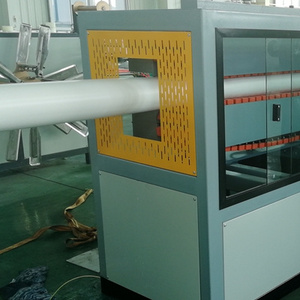

small size diameter pipe making machine:

-

small size diameter pipe making machine

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

132:65

-

Screw Speed (rpm):

-

200 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SEVENSTARS

-

Voltage:

-

Country Voltage

-

Dimension(L*W*H):

-

8900*1550*1150

-

Power (kW):

-

85

-

Weight:

-

4500 KG

-

Usage:

-

Water pipe, conduit pope and so on

-

Raw material:

-

PVC Powder+additatives

-

pvc pipe plastic machine factory:

-

pvc pipe plastic machine factory

-

PVC pipe workshop:

-

PVC pipe workshop

-

small size diameter pipe making machine:

-

small size diameter pipe making machine

Product Description

Specification

|

item

|

value

|

|

Application

|

PIPE

|

|

Plastic Processed

|

PVC

|

|

Condition

|

New

|

|

Output (kg/h)

|

100kg/h - 800kg/h

|

|

Screw Design

|

Double-screw

|

|

Screw Material

|

38CrMoALA

|

|

Screw diameter (mm)

|

65

|

|

Screw L/D Ratio

|

132:65

|

|

Screw Speed (rpm)

|

200rpm

|

|

Showroom Location

|

United States, France, Brazil

|

|

Place of Origin

|

China

|

|

|

Jiangsu

|

|

Brand Name

|

SEVENSTARS

|

|

Voltage

|

Country Voltage

|

|

Dimension(L*W*H)

|

8900*1550*1150

|

|

Power (kW)

|

85

|

|

Weight

|

4500KG-20500KG

|

|

Certification

|

ISO9001:2008/CE/SGS

|

|

Warranty

|

1 Year

|

|

After-sales Service Provided

|

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

|

|

Key Selling Points

|

Energy saving

|

|

After Warranty Service

|

Video technical support, Online support, Spare parts, Field maintenance and repair service

|

|

Local Service Location

|

United States, France, Morocco, Kenya, Argentina, Chile

|

|

Applicable Industries

|

Manufacturing Plant, Construction works , Energy & Mining

|

|

Marketing Type

|

New Product 2020

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Bearing, Motor, Pump, Gear, PLC, Pressure vessel, Engine, Gearbox, Screw

|

General description

PVC single cavity production line :

Φ20-Φ630 series PVC pipe extrusion machine line is mainly used in the manufacture of plastic PVC pipes with various diameters and wall thickness used in the industries such as agricultural and constructional plumbing,cable laying etc. This line is composed of conical twin screw extruder,Vacuum calibration tank,haul off,motors,cutter and stacker etc. The extruder and haul off methods are two-claw,three-claw four-claw,six-claw,eight-claw,ten-claw,twelve claw etc. You may choose saw blade cutting type or planetary cutting type. It is aditionaly attached with length counter and intensifying device. This line with reliable performance and high production eficiency. Our company can also manufacture special pipe production lines,e.g. spiral silencing pipe and core foaming pipe according to your requirements.

PVC double-pipe production line:

The production line is developed with the advanced technology of west Europe by our company. The main machine is SJSZ55/110 or SJSZ65/132 conical twin screw extruder is equipped with double-tubesingle control stainless steel spraying calibration,it avoids waste condition when one tube is adjusted and the other one is affected. The auto single-control double drawing machine and cuting machine arecombined with the front double calibration technology to make operation more flexible let you enjoy economic benefit which is brought by separate-control double tube extruding.

PVC four cavities production line:

Four cavities PVC electrical tube,water supply pipeextrusion line can extruder four pipes at same time onone machine.This line can save investment cost in factory buiding and production,which increase the capacity a lot and reduce production time.SJSZ65 conical twin-screw extruder can easily reach 5.5-6.5 ton/per day,the production speed take 16mm as example can get more than 8-10m/min.The whole line is composed of conical twin-screw extruder 65mm, 4 cavity mould,4 cavity coling calibration tank,4 station haul off,4 station cutter and 4 station tipping table.

Φ20-Φ630 series PVC pipe extrusion machine line is mainly used in the manufacture of plastic PVC pipes with various diameters and wall thickness used in the industries such as agricultural and constructional plumbing,cable laying etc. This line is composed of conical twin screw extruder,Vacuum calibration tank,haul off,motors,cutter and stacker etc. The extruder and haul off methods are two-claw,three-claw four-claw,six-claw,eight-claw,ten-claw,twelve claw etc. You may choose saw blade cutting type or planetary cutting type. It is aditionaly attached with length counter and intensifying device. This line with reliable performance and high production eficiency. Our company can also manufacture special pipe production lines,e.g. spiral silencing pipe and core foaming pipe according to your requirements.

PVC double-pipe production line:

The production line is developed with the advanced technology of west Europe by our company. The main machine is SJSZ55/110 or SJSZ65/132 conical twin screw extruder is equipped with double-tubesingle control stainless steel spraying calibration,it avoids waste condition when one tube is adjusted and the other one is affected. The auto single-control double drawing machine and cuting machine arecombined with the front double calibration technology to make operation more flexible let you enjoy economic benefit which is brought by separate-control double tube extruding.

PVC four cavities production line:

Four cavities PVC electrical tube,water supply pipeextrusion line can extruder four pipes at same time onone machine.This line can save investment cost in factory buiding and production,which increase the capacity a lot and reduce production time.SJSZ65 conical twin-screw extruder can easily reach 5.5-6.5 ton/per day,the production speed take 16mm as example can get more than 8-10m/min.The whole line is composed of conical twin-screw extruder 65mm, 4 cavity mould,4 cavity coling calibration tank,4 station haul off,4 station cutter and 4 station tipping table.

Product Description

Specification

|

Model/Item

|

Pipe range

|

Extruder

|

Max output

|

Max speed

|

Total power

|

|

PVC-50*2

|

16-50mm

|

SJSZ65/132

|

250kg/h

|

10 m/min

|

85 kw

|

|

PVC-63

|

16-63mm

|

SJSZ51/105

|

150 kg/h

|

10 m/min

|

60 kw

|

|

PVC-110

|

50-110mm

|

SJSZ55/110

|

180 kg/h

|

10 m/min

|

70 kw

|

|

PVC-160

|

63-160mm

|

SJSZ65/132

|

300 kg/h

|

5 m/min

|

90 kw

|

|

PVC-250

|

110-250mm

|

SJSZ80/156

|

400 kg/h

|

3.5 m/min

|

120 kw

|

|

PVC-315

|

160-315mm

|

SJSZ80/156

|

400 kg/h

|

3 m/min

|

160 kw

|

|

PVC-450

|

250-450mm

|

SJSZ92/188

|

700 kg/h

|

1.5 m/min

|

200 kw

|

|

PVC-630

|

315-630mm

|

SJSZ92/188

|

700 kg/h

|

0.9 m/min

|

230 kw

|

Detailed photo

Product packaging

Hot Searches