- Product Details

- {{item.text}}

Quick Details

-

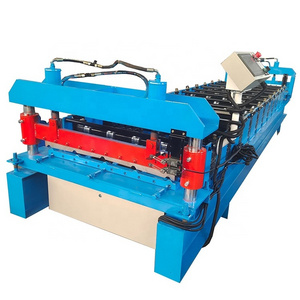

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

HE BEI CHINA

-

Brand Name:

-

HUA NUO

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

4700mm*1300mm*1200mm

-

Weight:

-

4 tons

-

After-sales Service Provided:

-

field installation, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Product name:

-

corrugated roof Forming Machine

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Control system:

-

PLC(imported Brand)

-

Thickness:

-

0.3--0.8mm

-

Material of rollers:

-

45# Cr Plated

-

Dia. Of Cutting Blade:

-

180-200)*20mm

-

Application:

-

Building Construction

-

After Warranty Service:

-

Video technical support, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE/ISO

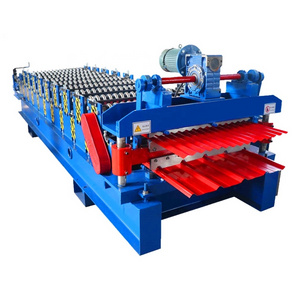

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

10 m -18 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

HE BEI CHINA

-

Brand Name:

-

HUA NUO

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

4700mm*1300mm*1200mm

-

Weight:

-

4 tons

-

After-sales Service Provided:

-

field installation, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Product name:

-

corrugated roof Forming Machine

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Control system:

-

PLC(imported Brand)

-

Thickness:

-

0.3--0.8mm

-

Material of rollers:

-

45# Cr Plated

-

Dia. Of Cutting Blade:

-

180-200)*20mm

-

Application:

-

Building Construction

-

After Warranty Service:

-

Video technical support, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE/ISO

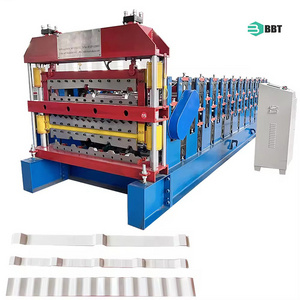

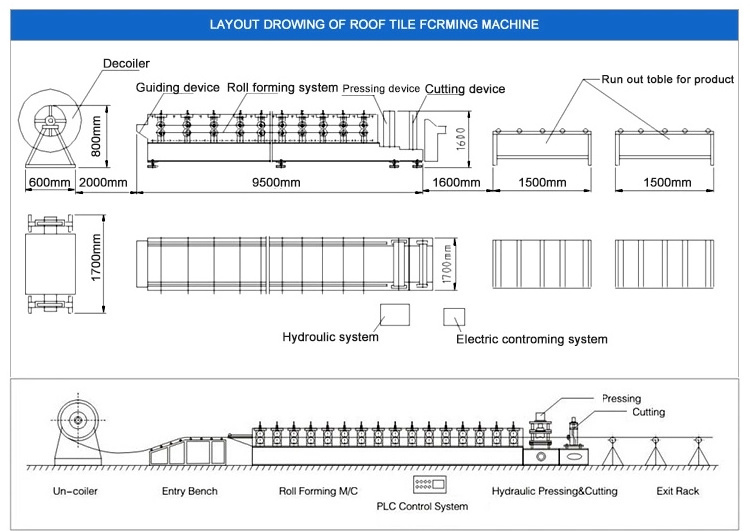

Automatic corrugated tile roofing sheets roll forming making machine

|

The total length of the equipment |

Length 4.77m width 1.3m height 1.2m |

|

The motor power |

Motor 5.5 Kw pump station 4Kw working voltage 380V or customized |

|

Production speed |

10 - 18 m/min |

|

The transmission way |

1 inch chain drive |

|

rack |

Large frame: 350H section steel |

|

shaft |

9 row of axis, diameter 70 axis |

|

The thickness of the plate |

14 mm |

|

Set of |

Galvanized pipe finishing, electrostatic spraying |

|

Wheel material |

45# steel hard chrome plating |

|

The molding part |

Divided into precision wheel rotation forming, forming effect is good, reduce the friction between wheels and raw materials, debugging convenient, fast. |

|

Numerical control system |

Easy control, letter press the button screen, counter |

|

shear |

Welded iron frame, hydraulic cylinder automatic shear |

|

The thickness of the plate |

0.3 - 0.8 mm |

|

Into the plate width |

1000 mm |

|

accessories |

Instruction book feeding rack a set |

|

Warranty period |

12 months |

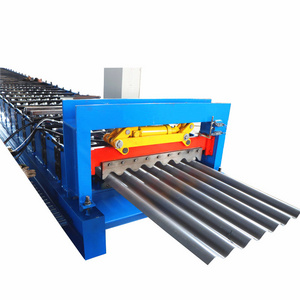

The process for work: decoiler→feeding→roll forming→measuring length→cutting to length→product to stand