- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LENO

-

Model Number:

-

LNP-1001

-

Place of Origin:

-

Zhejiang, China

-

Horsepower:

-

1/2HP-22HP

-

Outlet Size:

-

25mm-133mm

-

Power:

-

0.55KW-22KW

-

Product name:

-

sanitary stainless steel rotary lobe pump

-

Material:

-

SS304/316L

-

Certificate:

-

CE

-

Seal:

-

EPDM/PTFE

-

Flow rate:

-

0-200T

-

Frequency:

-

50 /60 Hz

-

Speed:

-

0-1000RPM

-

Type:

-

Rotor pump

-

Certification:

-

ce

Quick Details

-

Application:

-

Biofuel Industry, Drinking water treatment, Industrial Utilities, wastewater treatment

-

Pressure:

-

8Bar

-

Voltage:

-

220V-480V, 220V/380V/440V

-

Brand Name:

-

LENO

-

Model Number:

-

LNP-1001

-

Place of Origin:

-

Zhejiang, China

-

Horsepower:

-

1/2HP-22HP

-

Outlet Size:

-

25mm-133mm

-

Power:

-

0.55KW-22KW

-

Product name:

-

sanitary stainless steel rotary lobe pump

-

Material:

-

SS304/316L

-

Certificate:

-

CE

-

Seal:

-

EPDM/PTFE

-

Flow rate:

-

0-200T

-

Frequency:

-

50 /60 Hz

-

Speed:

-

0-1000RPM

-

Type:

-

Rotor pump

-

Certification:

-

ce

LENO lobe pump, also known as a rotary lobe pump, is a type of positive displacement pump commonly used for pumping viscous fluids and slurries. It operates by using two or more lobes (typically gear-shaped) that rotate in opposite directions within a pump casing. The lobes have a synchronized motion, creating a seal at the pump inlet and pushing the fluid or slurry through the pump.

|

material

|

SS304 or SS316L

|

|

|

||

|

Capacity

|

0-100T (Customized)

|

|

|

||

|

Pressure

|

0-8bar

|

|

|

||

|

Viscosity

|

1-1000000pas

|

|

|

||

|

rotors type

|

butterfly rotors/Trefoil rotor

|

|

|

||

|

temperature

|

0-200 celsius degree

|

|

|

||

|

relief valve

|

NO

|

|

0-3bar

|

||

|

mechnical seal type

|

Sinlge mechanical seal

|

|

Double flushed mechanical seal

|

||

|

connection type

|

Clamp

|

Union

|

Flange

|

||

|

Inlet outlet direction

|

Left and right or Up and down

|

|

|

||

|

Jacket

|

No

|

|

hotwater

|

||

|

motor type

|

Normal

|

Planetary

|

inverter

|

||

|

Speed

|

0-1000RPM

|

|

|

||

Product Parameters

|

Technical Parameters

|

|

|

|

|

||||

|

Model

|

Capacity/Per centum rotate (L)

|

Speed(RPM)

|

Flow(L/H)

|

Power(KW)

|

||||

|

LNP-3R

|

3L

|

100-500

|

300-800

|

0.55

|

||||

|

LNP-6R

|

6L

|

100-500

|

650-1600

|

0.75

|

||||

|

LNP-8R

|

8L

|

100-500

|

850-2160

|

1.5

|

||||

|

LNP-12R

|

12L

|

100-500

|

1300-3200

|

2.2

|

||||

|

LNP-20R

|

20L

|

100-500

|

2100-5400

|

3

|

||||

|

LNP-30R

|

30L

|

100-500

|

3200-6400

|

4

|

||||

|

LNP-36R

|

36L

|

100-500

|

3800-7600

|

4

|

||||

|

LNP-52R

|

52L

|

100-500

|

5600-11000

|

5.5

|

||||

|

LNP-66R

|

66L

|

100-500

|

7100-14000

|

7.5

|

||||

|

LNP-78R

|

78L

|

100-500

|

9000-18000

|

7.5

|

||||

|

LNP-100R

|

100L

|

100-500

|

11000-22000

|

11

|

||||

|

LNP-135R

|

135L

|

100-500

|

15000-30000

|

15

|

||||

|

LNP-160R

|

160L

|

100-500

|

17000-34000

|

18.5

|

||||

|

LNP-200R

|

200L

|

100-500

|

21600-43000

|

22

|

||||

|

We can customize the equipment according to customer requirements.

|

|

|

|

|

||||

Products Description

Operation Principle

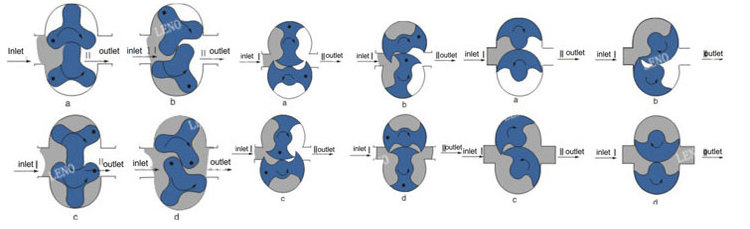

Rotor pump is also named rotary lobe pump, three-lobe pump, etc. When the 2 simultaneous reverse rotating rotors(with 2-4 gears)revolve, it produces suction force at the inlet(vacuum), which intakes the material delivered. The 2 rotors divide the rotor housing into many smaller parts and revo-Ive in the sequence of a→b→c→d. When it revolves to position a, only housing I is filled with medium. when it revolves to position b, housing B encloses part of the medium, when it goes to position c, housing A encloses medium, and finally it goes to position d, then housing A, B and II are interlinked and the medium is transported to the outlet. As this process is repeated, medium (material) is transpor-ted continuously.

Rotor pump is also named rotary lobe pump, three-lobe pump, etc. When the 2 simultaneous reverse rotating rotors(with 2-4 gears)revolve, it produces suction force at the inlet(vacuum), which intakes the material delivered. The 2 rotors divide the rotor housing into many smaller parts and revo-Ive in the sequence of a→b→c→d. When it revolves to position a, only housing I is filled with medium. when it revolves to position b, housing B encloses part of the medium, when it goes to position c, housing A encloses medium, and finally it goes to position d, then housing A, B and II are interlinked and the medium is transported to the outlet. As this process is repeated, medium (material) is transpor-ted continuously.

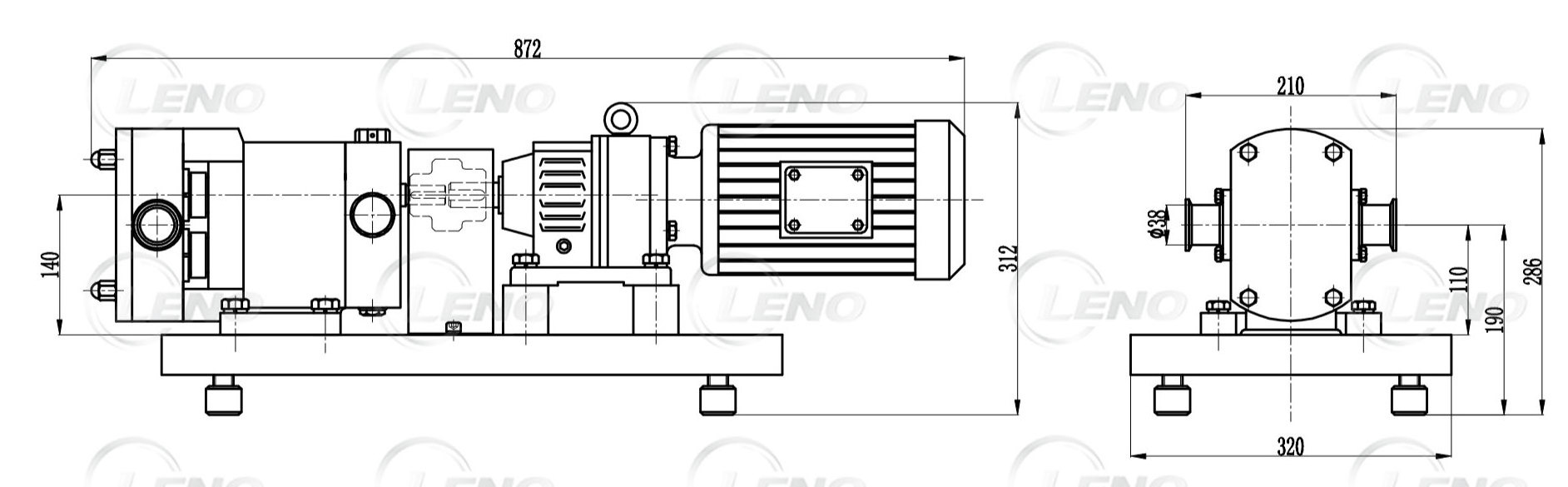

1.Screw cap 2.Pump cover 3.Seal ring 4.Cap 5.Seal ring 6.Rotor 7.Pump cavity 8. Mechanicaseal (stationary ring) 9.Mechanical seal(moving ring) 10.Seal ring 11.Bearing sleeve 12. Bearingcover 13. Seal gasket 14.Rubber oil seal 15.Bearing seat 16.Seal gasket 17.Bearing 18. Uppershaft 19.Lower shaft 20. Helicalgear 21.Stop washer 22.Cap 23.Screw 24.Pump body 25.Bearing 26.Rubber oil seal 27.Seal gasket 28.Bearing cover 29. Pin

More suitable for conveying media which containing large granular materials. The breaking rate of large granular materials is low. But on other hand it is not popular one for used. Because its pulsation is large and pressure is low, also the volume is small for the space of transferred materials.

lt is widely used one rotor. The volume is bigger than other type of rotors for the space of transferred materials. Also each performance is higher than other rotors. Just it has a certain rate of breakage to the particulate materials on the transport way.

The volume is more smaller for the space of transferred materials and breaking rate more higher when the quantity of rotary vane of rotor be increased, . Just the transport way more stable.

More suitable for conveying media which containing small and medium-size granular materials. The breaking rate to these materials is low and getting slightly pulsating. The volume is a little less than three-lobed rotor for the space of transferred materials.

WHY CHOOSE LENO LOBE PUMP

1,LENO Lobe pump set A Certain Gap Between Rotor And Rotor, No Friction Coefficient,So Pump Have A Long Service Life Time.

2.LENO Lobe pump can be Easy To Install And Disassemble,And It Is Convenient To Maintain, Clean .There Is Less Wearing Parts.

3.LENO Lobe pump with High Efficiency And Energy Saving, Stable Transportation, Low Failure Rate, No Leak Sealing And Low Noise.

4,.LENO Sanitary Lobe pump can transfer the Viscosity Of The Transportable Medium Is from 1 to 2000000 Cps, And The Pump Can Transfer Slurry Containing 70% Solids (Better Use the Inlet from the Top)

5.LENO Lobe pump also can Transfer Gas, Liquid And Solid Three-Phase Mixture Materials.

6,.LENO Lobe pump can be equipped With Vfd to adjust the speed of the motor.

7,.LENO Lobe pump can work with different place, Speical place which needs the lobe pump with the jacket to Avoid the Liquid to be Solid ,Like Chocolate.

8.LENO Lobe Pump can transfer different Temperature: -50 °C -250 °C. (It can use the Water Flushed mechanical seal and oil mechanical Seal)

9.LENO Lobe pump can be Reversal as well.

10.LENO Lobe pump can set up with safety valve to avoid the pressure to be higher.

11.LENO Lobe pump can provide the different Types Of Inlet/Outlet Connection: such as Flange Joint,Threaded,tri-Clamp, BSP etc.

11.LENO Lobe pump can provide the different Types Of Inlet/Outlet Connection: such as Flange Joint,Threaded,tri-Clamp, BSP etc.

12.LENO Lobe pump can provide the inlet to be top that can transfer the liquid with soloid and high viscosity easily.

13.LENO Lobe pump also can be used as the filling machine as well.

14.LENO Lobe pump can provide the various Seals of Type: Mechanical seal, Flushed mechanical seal, Oil flushed mechanical seal.

14.LENO Lobe pump can provide the various Seals of Type: Mechanical seal, Flushed mechanical seal, Oil flushed mechanical seal.

If you meet any problem of the Lobe Pump, Feel free to contact me.

Applicable to the fields of food, dairy, beverage, cosmetic etc industry.

a. Chemical Industry: Fat, Dissolvent, Resin, Paint, Pigment, Oil Agent etc.

b. Food Industry: Yogurt, Ice Cream, Cheese, Soft Drink, Fruit Jelly, Ketchup, Oil, Syrup, Chocolate etc.

c. Daily Chemicals: Facial Foam, Hair Gel, Hair Dyes, Toothpaste, Shampoo, Shoe Polish etc.

d. Nutrition Liquid, Biological Products etc.

Product Image

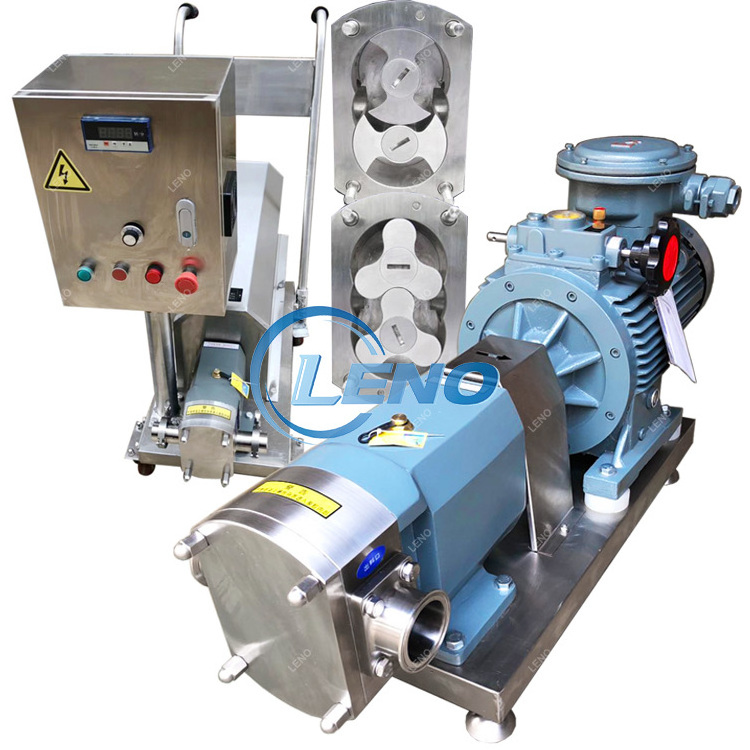

Lobe pump with emulsifier pump combination

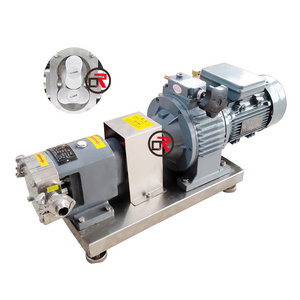

Standard Lobe pump with manual adjust speed

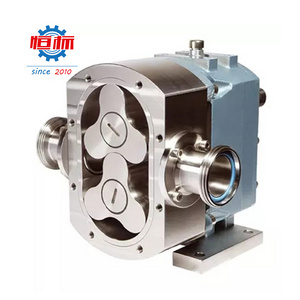

Hot water jacket Head of the Lobe pump

Hot water jacket lid of the Lobe pump

Lobe pump with Safety valve

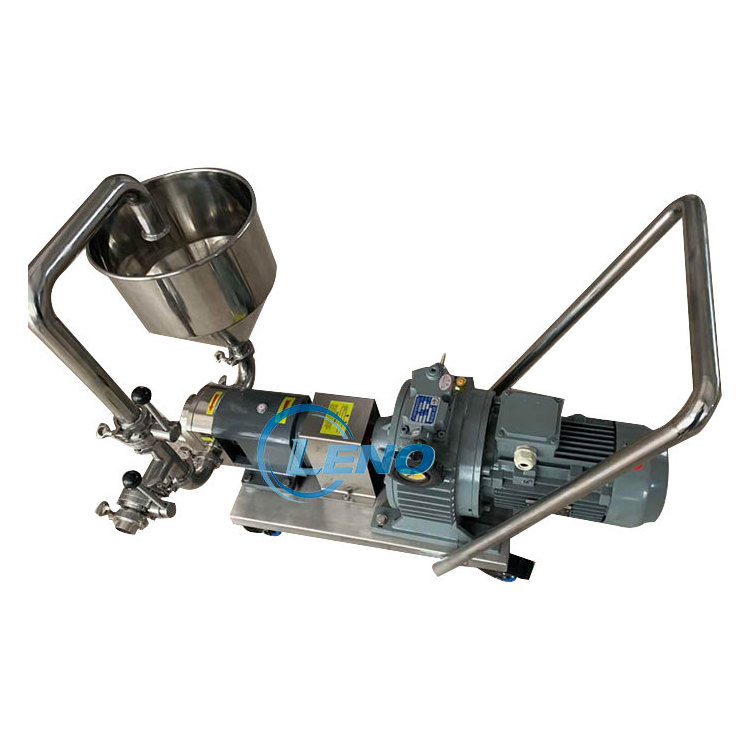

Top inlet lobe pump for high Viscosity

Recommend Related Products

Hot Searches