- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Raw material:

-

Fish Meal

-

Function:

-

Dog Food Extruder Production

-

Name:

-

Fish Pellet Machine

-

Material:

-

Stainless Steel Food Grade

-

Keywords:

-

Pet Snack Cat Dog Food Making Machine

-

Final product:

-

Dog Pet Feed Pellet

-

Processing Types:

-

Advance Extursion System

-

Feature:

-

Automatic Feed Pellet Machine

-

Advantage:

-

Easy Operation High Efficiency

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Darin

-

Weight:

-

1600 KG

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Raw material:

-

Fish Meal

-

Function:

-

Dog Food Extruder Production

-

Name:

-

Fish Pellet Machine

-

Material:

-

Stainless Steel Food Grade

-

Keywords:

-

Pet Snack Cat Dog Food Making Machine

-

Final product:

-

Dog Pet Feed Pellet

-

Processing Types:

-

Advance Extursion System

-

Feature:

-

Automatic Feed Pellet Machine

-

Advantage:

-

Easy Operation High Efficiency

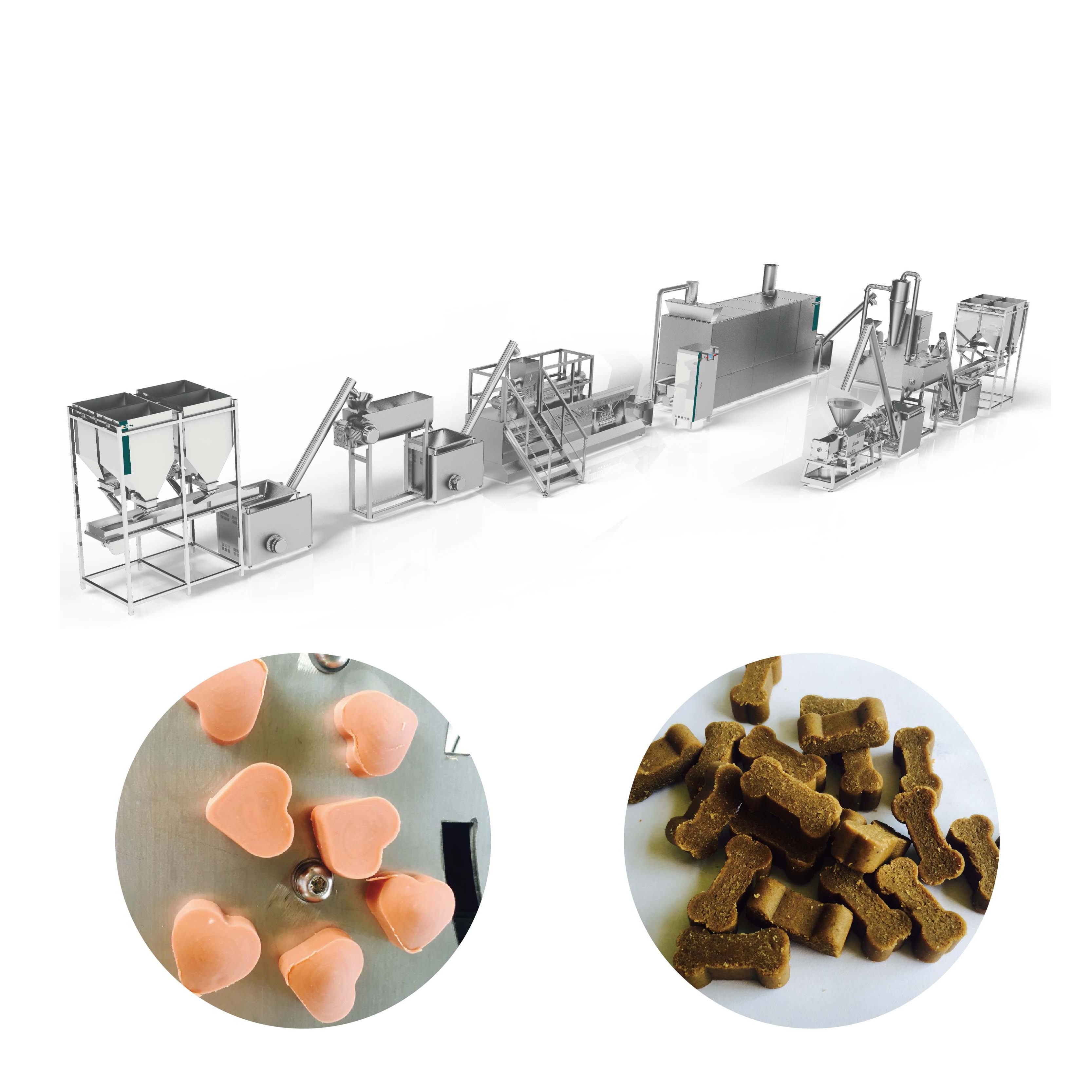

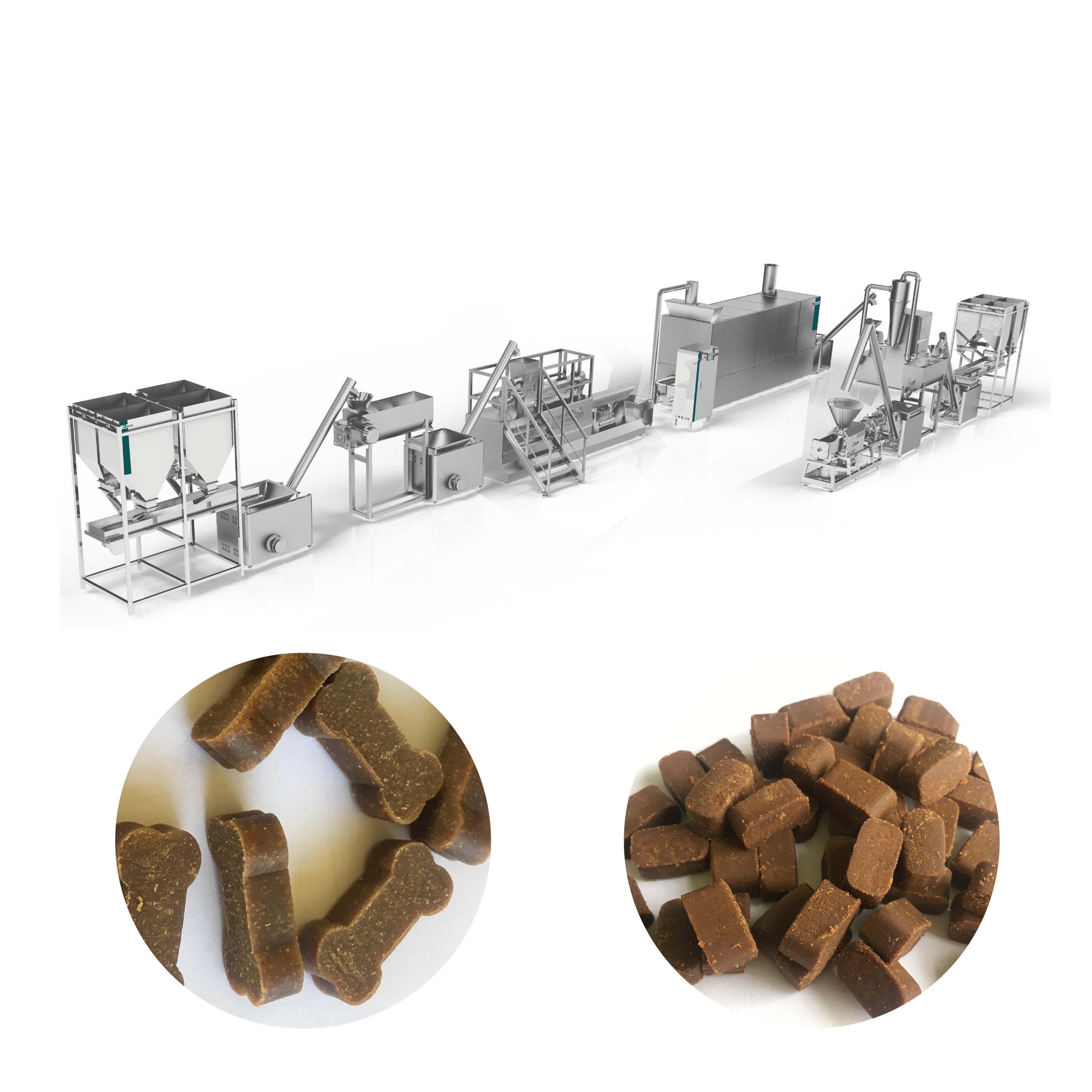

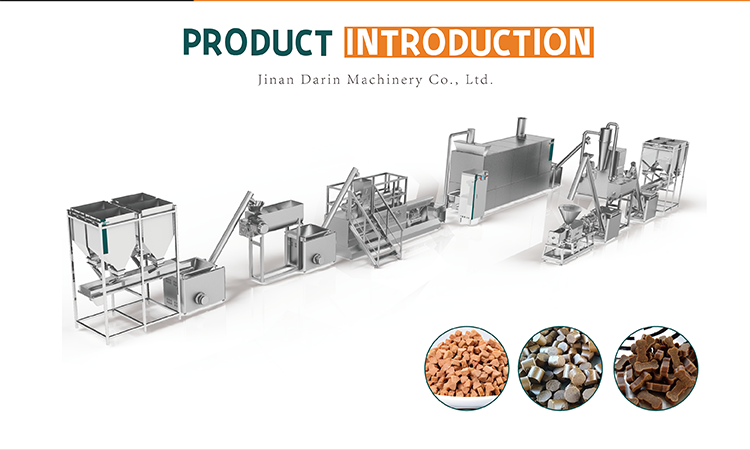

DR-126 Soft Pet Treat Processing Line is specially used to produce cold extruding and high meat content products, such as lecithin treats, jerky treats, core filling treats, nutrition soft treats etc. Also, shaped biscuits, core filling treats can be produced by easily change the molds. The shape of soft jerky treats can be heart, cylinder, chips, strip, etc.

|

Model

|

DR-126

|

|

Capacity

|

Single head extrusion: 100kg/hr

Double head extrusion: 200kg/hr |

|

Power

|

21kw

|

|

Hopper volume

|

65L

|

|

Screw diameter

|

126mm

|

|

Cooling type

|

Water circulation

|

|

Cylinder pressure

|

0.4-0.5Mpa

|

|

Weight

|

1200kg

|

|

Diamension

|

4300x900x2000mm

|

About Us

JINAN DARIN MACHINERY CO,LTD.

aSMember of APPA and Deputy PresidentUnit of SDPIA Darin is established in 2011and is a High-Tech Enterprise of ShandongProvince, specializing in development andsales of pet food machine, puff snack ma-chine,energy granola bar machine and support equipment.Now Darin machines havebeen exported to more than 70 countries ofthe world.

Keeping automation, quality and service inmind, always based on the diverse needs ofcustomers, Darin will be dedicated to pro-viding clients with satified product and fulllife after sales service.

1.We provide 1 year guarantee for our machine quality.

2.We provide testing machine service before making the order and/or before delivery machine.

3.We use famous brand motor and PLC (Siemens Brand) and good main electric parts (Schneider or Delixi).

4.We provide a one-stop service integrating design, measurement, production, delivery,installation, and after-sales service.

5.Our factory has passed the ISO 9001 international quality certification.

6.We provide customized service according customer idea to design our machine function.

7.Basic reference formula will be provided to help customer test their product.

8.Oversea after service (technical suggestion) in some countries, Such as Turkey, Brazil,Italy, Thailand and Serbia etc.

9.Online after service, video manual operation.

10.Our machines sold to 70 countries.

11.We provideCAD and 3D design layout.

12.We select raw material suppliers carrying the certificates that 100% guarantee the materials do no harm to the environment.

LAYOUT DESIGN

We make accurate factory layout design according to customer's factory size; if the customer needed, we could make workshop design with electricity power,water supply, gas power, material storage, finalstorages, worker's restroom, etc.

ENGINEER VISA

After delivering machines to client's factory, we start to apply for the Visa to client's country immediately, normally the vessel needs 20-60 days to the required port, so we have enough time to get the Visa. While the machines arrives your factory , our engineers are ready to start for the commissioning service.

SHORTEST TIME

1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time.

RESPONSIBILITY OF CUSTOMER

The engineer's round-trip flight tickets, accommodation and daily salary are on client's account.

TRAINING OPERATION

Our engineers have responsibility to train and teach the workers how to operate, clean, maintain and repair all the machines, until the workers could well operate the processing line.

WARRANTY PERIOD

It normally costs 10 days for the commissioning service, and we supply 1 year guarantee from the date of completion of commissioning service.

Q:During epidemic period, how should we install the processing line without any experience? A:1)Before delivery, we will take

detailed operation video to show how to assemble each machine,how to operate and maintain the line.

2) Operation manual, circuit diagram etc in English version will be provided.

3) Online support available. If any questions during installation or production, our engineer will help to solve by video call or

zoom meeting.

Q:If we show our workshop size, can you design layout for the whole line?

A:Auto CAD layout will be provided as client's workshop size.

Q:If some parts break after warranty, what should we do?

A:Darin supply full-life after sales service, whenever new parts needed, we will help to supply new replacements at reasonable

price & in shortest time.

Q:How long is your machine's guarantee time?

A:One year from the machine arrive at your factory.

Q:Could you afford technician team to guide our installation and commissioning?

A:Oversea commissioning service provided, our technician will help to install the machine, and teach local workers about operation

and maintenance. Buyer should pay for the technician's round flight ticket , accommodation and salary.

Q:Could we visit your factory to check the machine carefully and closely?

A:You're more than welcome to visit Darin, we will provide machine test running, face to face discussion and turkey project design

solution.

Q:Why us Darin?

A:With more than 20 years experience in designing and manufacturing food machines, Darin feels proud and onfident to introduce our

machines to you and your esteemed company as one of the most competitive supplier in this business. What we strive to do all the

time is providing innovative machines for our customers.

Q:What materials Darin adopted in those machines?

A:All the parts that touched with Darin will use food grade SS304, PU belt, strong carbon steel or appointed material for the

bearing parts. High quality electronic components supplied by well-reputated company like Siemens and WEG.

Q:How to get a proper quotation with good price?

A:Contact us directly and provide as more information as you can, like the product pictures, weight, capacity, voltage and

frequency of the motor requested, delivery date if there's urgently need. Quotation will be sent to your inbox immediately once

everything is clear.

Q:When will the machines be shipped?

A:Normally around 45 working days.

Q:How about the after-sales service?

A:Darin will always provide best full-life after sales service, no matter when customers have any problem or questions, we will

reply them very soon.

detailed operation video to show how to assemble each machine,how to operate and maintain the line.

2) Operation manual, circuit diagram etc in English version will be provided.

3) Online support available. If any questions during installation or production, our engineer will help to solve by video call or

zoom meeting.

Q:If we show our workshop size, can you design layout for the whole line?

A:Auto CAD layout will be provided as client's workshop size.

Q:If some parts break after warranty, what should we do?

A:Darin supply full-life after sales service, whenever new parts needed, we will help to supply new replacements at reasonable

price & in shortest time.

Q:How long is your machine's guarantee time?

A:One year from the machine arrive at your factory.

Q:Could you afford technician team to guide our installation and commissioning?

A:Oversea commissioning service provided, our technician will help to install the machine, and teach local workers about operation

and maintenance. Buyer should pay for the technician's round flight ticket , accommodation and salary.

Q:Could we visit your factory to check the machine carefully and closely?

A:You're more than welcome to visit Darin, we will provide machine test running, face to face discussion and turkey project design

solution.

Q:Why us Darin?

A:With more than 20 years experience in designing and manufacturing food machines, Darin feels proud and onfident to introduce our

machines to you and your esteemed company as one of the most competitive supplier in this business. What we strive to do all the

time is providing innovative machines for our customers.

Q:What materials Darin adopted in those machines?

A:All the parts that touched with Darin will use food grade SS304, PU belt, strong carbon steel or appointed material for the

bearing parts. High quality electronic components supplied by well-reputated company like Siemens and WEG.

Q:How to get a proper quotation with good price?

A:Contact us directly and provide as more information as you can, like the product pictures, weight, capacity, voltage and

frequency of the motor requested, delivery date if there's urgently need. Quotation will be sent to your inbox immediately once

everything is clear.

Q:When will the machines be shipped?

A:Normally around 45 working days.

Q:How about the after-sales service?

A:Darin will always provide best full-life after sales service, no matter when customers have any problem or questions, we will

reply them very soon.

Hot Searches