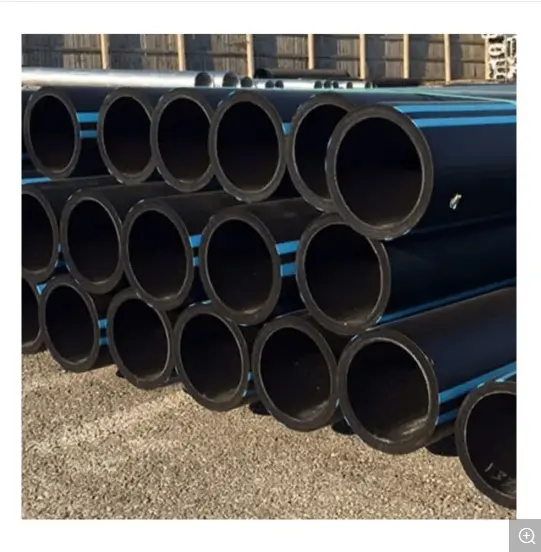

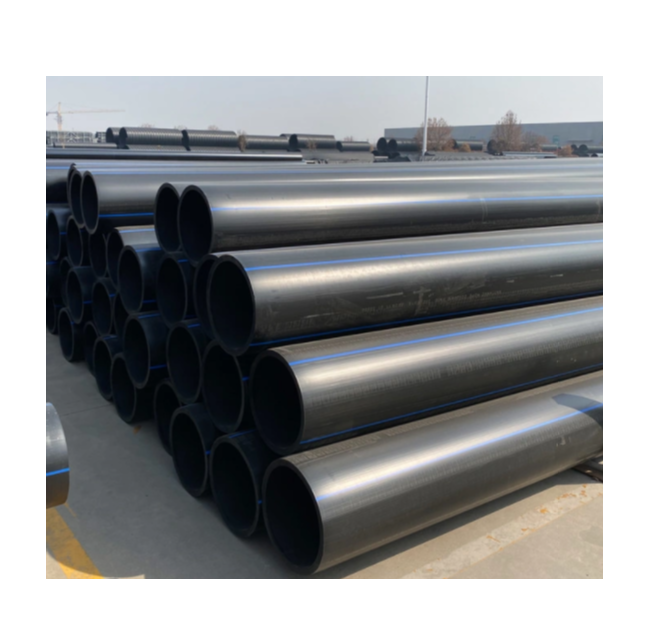

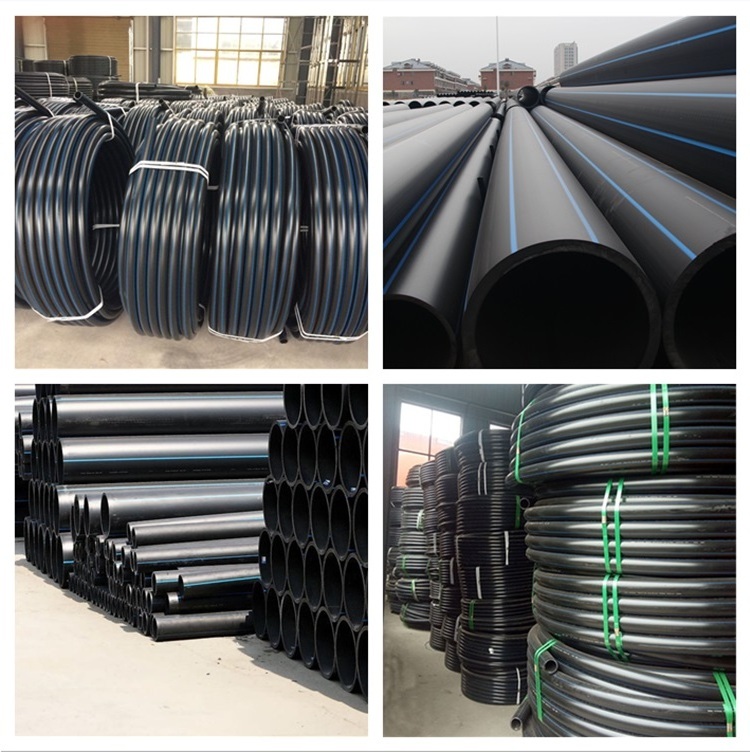

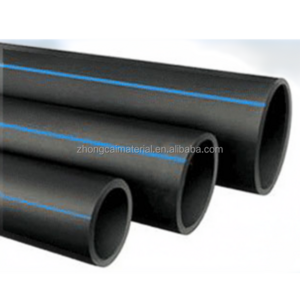

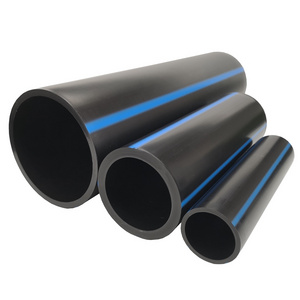

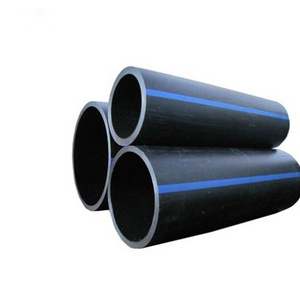

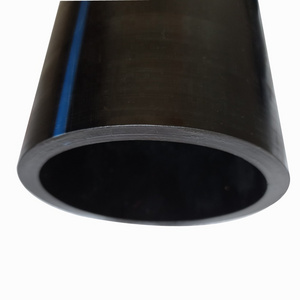

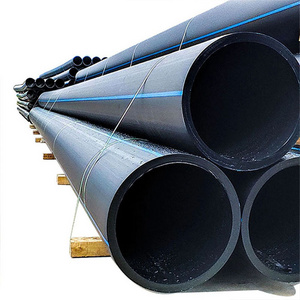

HDPE pipe is made of high density polyethylene resin.The product's physical properties make it applicable to open-trench, horizontal directional drilling,pipe-bursting and slip-lining installations.

It can be manufactured with the color striping to identify application, such as blue stripe for potable water, yellow stripe for gas applications and red stripe for mining or cable protection applications.

It can be manufactured with the color striping to identify application, such as blue stripe for potable water, yellow stripe for gas applications and red stripe for mining or cable protection applications.

Main application as follows:

1. Urban potable water pipeline network system.

2. Replaceable cement pipe, iron pipe and steel pipes.

3. Fire fighting pipeline.

4. Landscaping water supply network.

5. Sewage discharge pipes.

6. Ore and mud transfers.

7. Agricultural irrigation pipe.

2. Replaceable cement pipe, iron pipe and steel pipes.

3. Fire fighting pipeline.

4. Landscaping water supply network.

5. Sewage discharge pipes.

6. Ore and mud transfers.

7. Agricultural irrigation pipe.