- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LML

-

Product name:

-

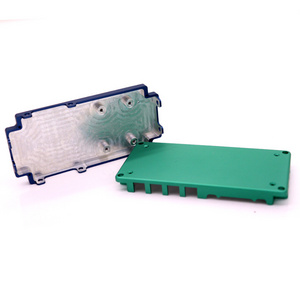

High Precision Industrial Sewing Machine Spare Parts

-

Process:

-

CNC Machining Center+CNC Machining Turning

-

Processing Level:

-

3 4 5 6 Axis CNC Machining Service

-

Item Name:

-

CNC Machining Machine Parts

-

Delivery Time:

-

20 Days From The Deposit

-

Quality Control:

-

100% Inspection Before Shipment

-

Certification:

-

ISO 9001:2008

-

Tolerance:

-

0.003mm~0.01mm

-

Drawing files:

-

CAD/UG/PROE etc

-

OEM & ODM:

-

Welcome

Quick Details

-

Machine Type:

-

Sewing Machine

-

Type:

-

Shafts

-

Use:

-

Industrial

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LML

-

Product name:

-

High Precision Industrial Sewing Machine Spare Parts

-

Process:

-

CNC Machining Center+CNC Machining Turning

-

Processing Level:

-

3 4 5 6 Axis CNC Machining Service

-

Item Name:

-

CNC Machining Machine Parts

-

Delivery Time:

-

20 Days From The Deposit

-

Quality Control:

-

100% Inspection Before Shipment

-

Certification:

-

ISO 9001:2008

-

Tolerance:

-

0.003mm~0.01mm

-

Drawing files:

-

CAD/UG/PROE etc

-

OEM & ODM:

-

Welcome

1 . While in the process of customer designing, we can help customers design the best products by using different processing procedures to achieve good function and save costs according to the application.

2 . We are familiar with the characteristics of various materials, we recommend appropriate flexibility, hardness, and electrical conductivity materials to customers according to their different requirements, for example, some customers products need to be soldered, so it is better to do nickel plating for the surface.

3 . For the surface treatment, we can do nickel plating, zinc plating, tin plating, common anodizing, and hard anodizing; for the anodizing, we can offer a variety of colors, such as black, red, orange, blue, etc.; if customers demands on the appearance of the product are high, we would ask our engineers to go to the surface treatment supplier site to control the quality of surface.

4 . For the LOGO design, we can design different colors, different fonts, concave and convex shape as well as screen printing, laser engraving style on the surface of product according to customer requirements.

5 . We can provide small quantities of samples to customer for testing

6 . We can provide processes for some special materials, such as: titanium, molybdenum, tungsten alloy and so on.

7 . For the quality control : we provide samples to customer for checking before production; we will not produce until the sample is approved; we will do the product inspection randomly in the process of production to detect the problem in time, we also will select random products to customers for checking according to customers requirements after the completion of the production before shipping. For the products with high assembly requirements, we will ask customers to provide the assembly parts, to ensure that the products can be assembled ok before shipment.

8 . Provide valuable pictures anytime: provide clear pictures of samples to customers for checking before the shipment; provide pictures of products which is in the process of producing; provide the detail packaging pictures showing the quantity and packaging of each product clearly after the completion of producing.

9 . Freight advantage: many customers who cooperate with us for many years feedback that the freight charges that we offered is much lower than the costs that the customers arrange the transportation by themselves, in general, the price can be cheaper by 30 percent to 50 percent, which help customers save shipping costs greatly.

10. Efficiency: Our sales department communicates with customers by using a variety of online tools (Skype, MSN, Trademanager ...), telephone, and e-mail, and adjusts the working hours according to customer time difference to keep in touch with customers and answer customer inquiries at any time, customers can use PAYPAL and other online payment platform to pay a small amount of sample fee to shorten the sample production time.

|

Materials |

brass,copper,stainless steel etc |

|

Industry Standards |

DIN/ ISO 9001:2008 RoHS complicant |

|

Minimum Order Quantity (MOQ) |

1 piece,Support LCL order |

|

Production Capacity |

2500000 pieces per week |

|

Lead Time |

15-20 days from deposit |

|

Payment Term |

L/C, T/T, Escow, Paypal, Western Union, Cash |

|

Quality control |

RoHS tester , callipers , salt spary tester , 3D coordonate measuring instrument |

|

Machines/equipment |

Stamping machines 15 sets (1 set of 120 tonnage ,3 sets of 80 tonnage , 8 sets of 65 tonnage , 3 sets of 45 tonnage) ,CNC center machins 2 sets automatic lathe turning parts 10 sets , electrical contact rivets machines 10 sets ,rivets machines 30 sets ,spring machines 10 sets |

|

Other Service |

OEM &OEM, Customized Specification, One to One Communication, Free Samples |

|

Additional |

1)Sample Order and Small Order are acceptable;

|

|

Our Website |

www.lmlmetalparts.com www.lmlmetalwork.com www.lmlmetalwork.en.alibaba.com www.lmlmetalwork1.com |

RELATED PRODUCTS

QUALITY CONTROL

Please Click " Contact US " To Place An Order If You Are Interested In Our Products!!!

1.Are you a trade company or a manufacturer?

A:We are a manufacturer specialized in hardware fittings production for more than 20 years, main products include cnc machining parts,metal stamping parts,rivets,aluminum profile, electrical contact etc,we offer OEM & ODM service.

2.What is your delivery date?

A:The delivery date is 15~20 days after receipt of payment.

3.How is the material used for your product?

A:The material we used for our product is environmental & safe.

4.What is your payment terms?

A:30%~50% deposit,the balance before shipment.

5.How is the quality of your product?

A:100% quality inspection before shipment,the detect rate is less than 0.7%.