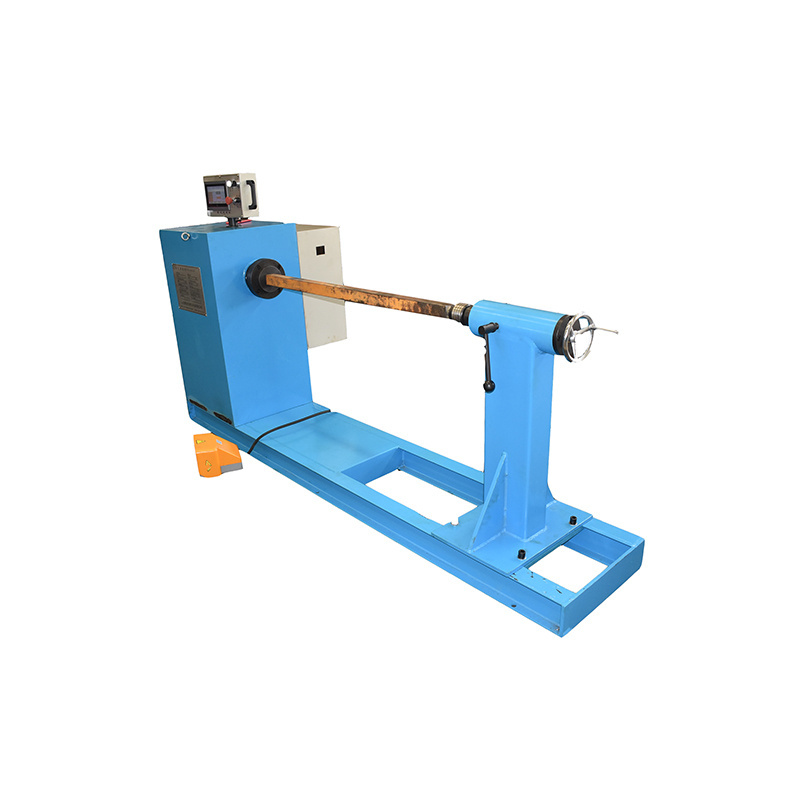

Guide rail and tailtock: The tailstock is integrated with the main box,which is mainly composed of tailstock,live center and guide rail.The tailstock can be moved axially on the guide rail of the base manually to meet the needs of different length linear dies.By rotating the hand wheel,the live center can be extended or returned,which is convenient to move the mold up and down,and improve the strength.The locking handle can lock the top idler and support its weight.

Electronic control system: The electronic control system is composed of electric control cabinet, frequency converter,counter or optional(CNC panel:the number of deceleration turns can be set at will and slow stop),high precision encoder and other electrical appliances. The speed of the spindle is controlled by frequency converter and gear,and the spindle speed and the number of turns can be displayed. The high precision encoder can count forward and backward,and has the function of power-off memory and automatic stop after setting the number of the turns.The whole winding process is operated by foot switch and button.