- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

INNWAI

-

Power:

-

19

-

Dimension(L*W*H):

-

4345*2200*2265mm

-

Weight:

-

5.6

-

Number of station:

-

24

Quick Details

-

Production Capacity:

-

1600pairs/8hours

-

Voltage:

-

380v

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

INNWAI

-

Power:

-

19

-

Dimension(L*W*H):

-

4345*2200*2265mm

-

Weight:

-

5.6

-

Number of station:

-

24

Product Description

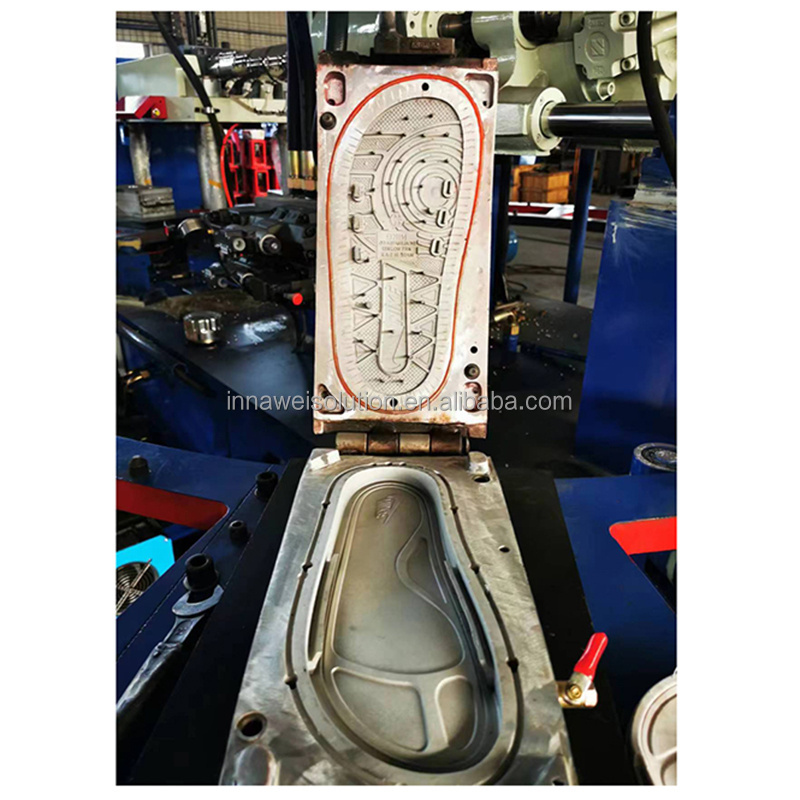

Machine advantages FEATURES:

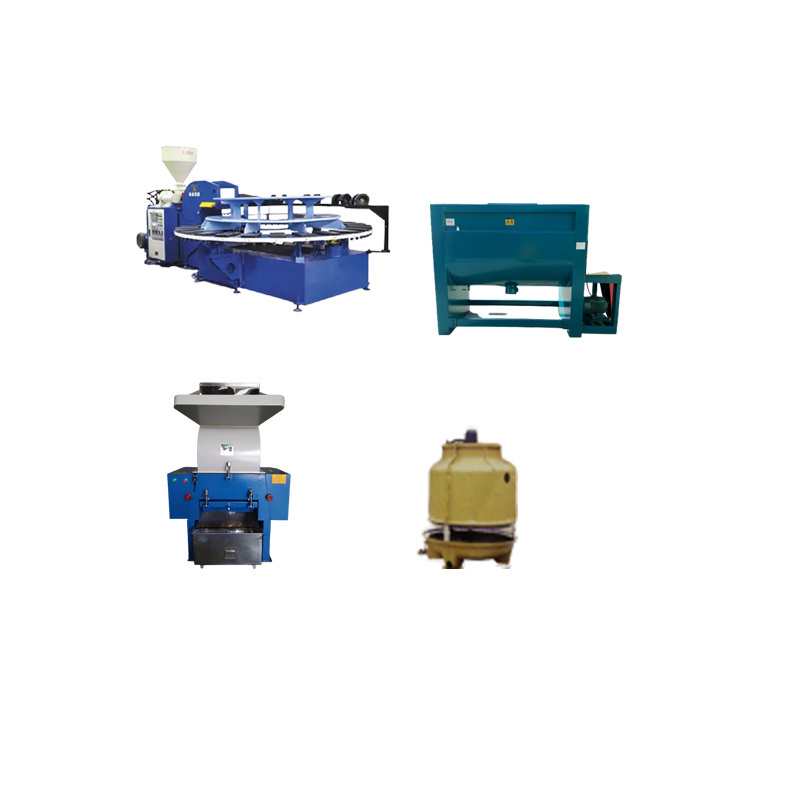

The Rotary twenty-four station blowing slippers making machine can produce PVC slippers of different shapes with an output of one thousand and two hundred-one thousand and five hundred/pair The production line can also use used slippers for recycling

This production line requires small investment and large profits1.Perfect circuit protection such as over load protection, short circuit protection or voltage-lose protection. Ensure the safety of workers

2. Intelligent design, The machine is controlled by programming controller. 3.Easy to operate, It adopts a Graphic panel as a human-machine interface, you can easily set mold, time, pressure, meter etc. 4.Automatic rotary platform. 5. Product quality is good. With twice injection system to improve the injecting speed and smoother the products. 6.The screw is transmitted by hydraulic motor which has less noise

7.The major mechanical movements, as injecting, feeding, discrotating, mould clamping etc… all controlled by programmable controller to have the movements more precise.Equipped digital-type proportional controller to control mould-clamping, injection and feeding pressures at the right time and more accuracy. 8.Equipped blowing system, the products produced are lightweight, soft with shining surface, the weight would be 20%-30% less then that made in conventional way 9.Recycle material can be injected. The products have good quality and super lightweight, almost the same as those made by all new material. 10.Automatic hydraulic mould opening device with the control system to make the movements fast and positive, as well labor saving. 11.Unique structure design has more capacity for much bigger moulds, also equipped mould cooling device for operating simply and making products perfectly.

Specification

FAQ

Hot Searches