- Product Details

- {{item.text}}

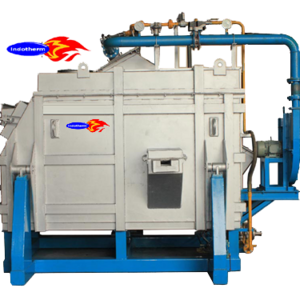

Quick Details

-

Voltage:

-

380 - 415

-

Dimension(L*W*H):

-

12 FT X 10 FT X 12 FT

-

Weight (T):

-

4 T

-

Power (kW):

-

12

-

Specification:

-

Automatic operation

-

Can Melt:

-

contaminated aluminium with paint, oil, with iron and aluminium dross

-

Equipment Description:

-

Molten slag, Mixed waste, Aluminum, Zinc, light metal waste

-

Furnace Construction:

-

Abrasion resistant castable, high density insulation board,.

-

Burner:

-

Double pass burner

-

Flue:

-

Natural Gas

-

Door:

-

Pneumatic Operated 1,100~2,000 mm

-

Control System:

-

Fully Automatic Proportional-integral controller

-

Certification:

-

ISO 9001-2008

Quick Details

-

Place of Origin:

-

Haryana, India

-

Marketing Type:

-

New Product 2023

-

Brand Name:

-

INDOTHERM EQUIPMENT CORPORATION

-

Voltage:

-

380 - 415

-

Dimension(L*W*H):

-

12 FT X 10 FT X 12 FT

-

Weight (T):

-

4 T

-

Power (kW):

-

12

-

Specification:

-

Automatic operation

-

Can Melt:

-

contaminated aluminium with paint, oil, with iron and aluminium dross

-

Equipment Description:

-

Molten slag, Mixed waste, Aluminum, Zinc, light metal waste

-

Furnace Construction:

-

Abrasion resistant castable, high density insulation board,.

-

Burner:

-

Double pass burner

-

Flue:

-

Natural Gas

-

Door:

-

Pneumatic Operated 1,100~2,000 mm

-

Control System:

-

Fully Automatic Proportional-integral controller

-

Certification:

-

ISO 9001-2008

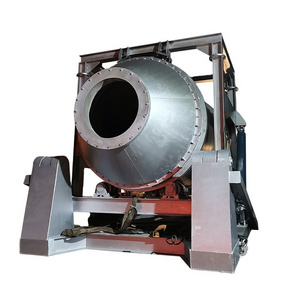

ALUMINIUM MELTING ROTARY FURNACE

TILTING ROTARY FURNACE

Tilting rotary furnace is a new design introduced in the field of aluminum smelting field. Earlier aluminum was recycled by the traditional rotary furnace which was very risky and uneconomical.

But with this new design and precise technology smelters have now the option to control their increasing fuel cost and yet 30-40 % faster production as compared to traditional rotary furnace.

Oxy-fuel combustion is a new technique that is used by smelters where instead of traditional blowers we use pure oxygen to burn the fuel. For e.g. Gas cutting where pure oxygen is combined with gas which makes the combustion process so effective that it is able to cut through the mild steel.

Less Fuel consumption | Increased Thermal Efficiency |Salt Consumption Low | Metal Recovery High | Metal Loss low | Productivity high

(IEC#TRF 03)

Tilting Rotary Furnace is a universal solution for processing all kind of materials, such as:

-

Dirty scraps, with dust, paint, plastics

-

Foundry casting returns

-

Automotive casting parts with ferrous particles

-

Aluminium cans, UBC

-

Chips, turnings

- White and black drosses

Competitive Advantages of the product Some Salient features of Rotary Tilting Furnace are :

-

Amplified productivity

-

Reduced operating costs

-

Larger profit

-

Rise in metal recovery

-

Low smoke happy operators

- With reduced salt dross portion is lesser hence land fill and secondary smelters have more metal yield over dross

|

Supplier Product Code |

IEC#TRF3 |

|

Main Markets/Key Customers |

QATAR| LUXEMBOURG | SINGAPORE | NORWAY | BRUNEI| UNITED ARAB EMIRATES| UNITED STATES| HONG KONG| SWITZERLAND| NETHERLANDS |

|

Delivery Terms |

Export Worthy Packing | Reliable Shippers | Online tracking of your goods | Cost , Insurance and Freight will be done from here |

|

Delivery Lead Times |

20 days |

|

Payment Terms |

• 30 % Advance against Purchase Order.

|

|

Min Quantity |

01 |

|

Price Information |

For Price Information please contact us |

|

Quality Process Certifications |

ISO 9001-2008 |

Since its establishment in 1991, Indotherm Equipment Corporation has focused on manufacturing, exporting, and supplying high-standard furnaces and belt conveyors. As an ISO 9001:2008 certified firm, our product range includes Crucible Furnace, Rotary Furnace, Hydraulic Tilting Furnaces, Reverberatory Furnaces, and Tilting Reverberatory Furnaces. Our primary objective is to provide products that prioritize safety and environmental friendliness, with a notable emphasis on energy-saving capabilities and reduced fuel consumption.

To ensure product quality, we maintain a directory of authorized vendors and conduct thorough research to select reliable suppliers. The raw materials undergo stringent quality checks by both the vendors and our own quality tests, ensuring compliance with industry standards. Our commitment to quality has garnered praise from clients, enabling us to establish a strong market position based on exceptional service and top-notch products.

Equipped with cutting-edge machinery, our packaging unit ensures secure export and delivery of products worldwide. Our dedicated team stays updated with the latest technology, enabling us to deliver high-class products. Under the guidance of Mr. C. L. Tripathi, who prioritizes customer satisfaction and environmental safety, we continuously strive to deliver superior, energy-efficient products. Indotherm Equipment Corporation is committed to providing high-quality products, advancing the aluminum industry, and maintaining customer satisfaction.

Overall, Indotherm Equipment Corporation is dedicated to delivering high-quality products, maintaining customer satisfaction, and contributing to the advancement of the aluminum industry.