- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product

-

Weight (KG):

-

16000 KG

-

Power (kW):

-

38.5

-

Overall Size:

-

Approx. 12,600mm*2,200mm*2,500 mm

-

Weight:

-

Approx. 16000 kg

-

Power Supply:

-

380V 50Hz or customized

-

Total Power:

-

38.5 kW

-

Pneumatic Load:

-

6 bar

-

Working Table:

-

2730*1260mm*40mm

-

Max. Working Height:

-

50mm

-

Working Cycle:

-

2 to 4 min per time

-

Heating System:

-

Oil heating and transfer

-

Optional:

-

Auto film rack

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Cambery

-

Machine Type:

-

vacuum membrane press machine

-

Marketing Type:

-

New Product

-

Weight (KG):

-

16000 KG

-

Power (kW):

-

38.5

-

Overall Size:

-

Approx. 12,600mm*2,200mm*2,500 mm

-

Weight:

-

Approx. 16000 kg

-

Power Supply:

-

380V 50Hz or customized

-

Total Power:

-

38.5 kW

-

Pneumatic Load:

-

6 bar

-

Working Table:

-

2730*1260mm*40mm

-

Max. Working Height:

-

50mm

-

Working Cycle:

-

2 to 4 min per time

-

Heating System:

-

Oil heating and transfer

-

Optional:

-

Auto film rack

PRODUCT INFORMATION

TECHNICAL CHARACTERISTICS

|

Overall Size

|

Approx. 12,600mm*2,200mm*2,500 mm

|

|

Weight

|

Approx. 16000 kg

|

|

Power Supply

|

380V 50Hz or customized

|

|

Total Power

|

38.5 kW

|

|

Pneumatic Load

|

6 bar

|

|

Control System

|

SIEMENS® PLC with full color touch screen.

|

|

Electronic Components

|

Schneider® or equivalent

|

|

Pneumatic Components

|

AirTac® or equivalent

|

|

Working Table

|

2730*1260mm*40mm

|

|

Max. Working Height

|

50mm

|

|

Vacuum Pump

|

Universal®

|

|

Pressure

|

Negative: 0 to -0.095 mPa

Positive: 0.5 to 0.6 mPa Membrane: 0.3 to 0.5 mPa |

|

Working Cycle

|

2 to 4 min per time

|

|

Heating System

|

Oil heating and transfer

|

|

Optional

|

Auto film rack

|

DETAILS DISPLAY

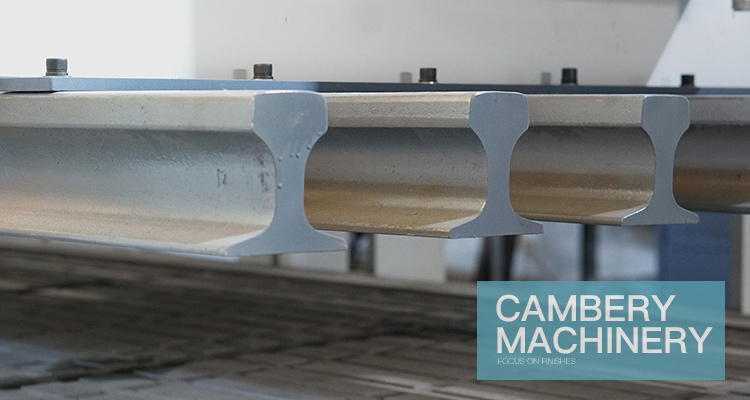

Premium thick steel frame.

●

Heavy-duty rail track and 100mm thick solid integrated steel base.

●

Robust hydraulic pressing system.

●

Rapid membrane replacing design.

●

Siemens® PLC control system with user-friendly HMI.

●

Quality electric components.

●

Quality pneumatic components.

●

Powerful and durable vacuum pump, with large volume tank.

●

Reliable pneumatic connection.

●

One-piece-made aluminum working table.

● Dual working table with fast control button.

● Auto pneumatic cutting.

● Auto pneumatic cutting.

OPTIONAL

●

Multi film rack, max. storing 9 roll films.

● One-key exchanging.

● One-key exchanging.

APPLICATION

3D laminates provide exceptional design flexibility for producing customized panel features such as compound curves, grommet holes, spill containment and contoured edge treatments that are ergonomically friendly. 3D laminates can be specified in a variety of thicknesses and surface coatings to enhance their excellent durability and impact resistance.

HOT SALE

COMPANY OVERVIEW

WELCOME TO VISIT US

Cooperation with up to 50 countries around the world.

Cooperation with up to 50 countries around the world.

OUR CERTIFICATION

FAQ

Q1. Warranty

A1. 12 months warranty is effective from the date of acceptance of the machine.

Q2. Payment Terms

A2. TT 30% down payment, 70% before shipment.

Q3. Delivery Time

A3. 15-30 working days from the receipt of the down payment.

Q4. Machine installation

A4. Cambery could assign the technician to the place for the on-site installation if requested by the purchaser.

Q5. Technical Support

A5. Every machine is assigned by a specialist. The response is available within 12 hours while the solution for the

troubleshooting is provided within 48 hours.

Q6. Demo and Testing

A6. Cambery built a training center for the clients and employees to study the machines operation. You are welcome to visit our factory anytime for the machines’ demo. Furthermore, we could run the machine with the materials provided by you and help you achieve your business efficiently.

A1. 12 months warranty is effective from the date of acceptance of the machine.

Q2. Payment Terms

A2. TT 30% down payment, 70% before shipment.

Q3. Delivery Time

A3. 15-30 working days from the receipt of the down payment.

Q4. Machine installation

A4. Cambery could assign the technician to the place for the on-site installation if requested by the purchaser.

Q5. Technical Support

A5. Every machine is assigned by a specialist. The response is available within 12 hours while the solution for the

troubleshooting is provided within 48 hours.

Q6. Demo and Testing

A6. Cambery built a training center for the clients and employees to study the machines operation. You are welcome to visit our factory anytime for the machines’ demo. Furthermore, we could run the machine with the materials provided by you and help you achieve your business efficiently.

Hot Searches