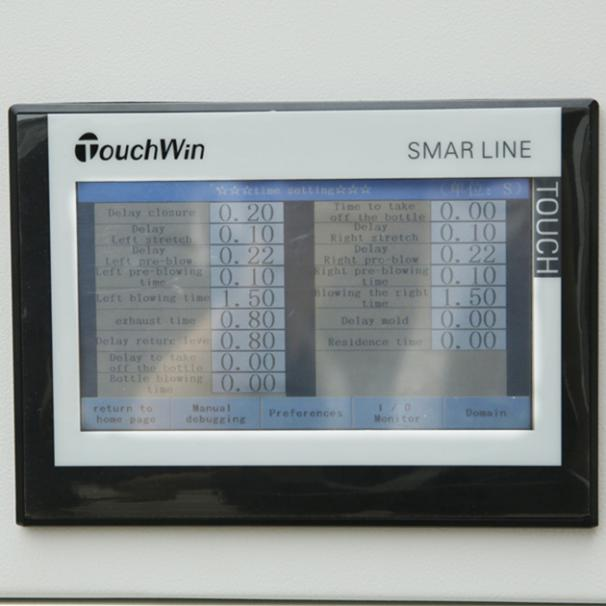

PLC with touch screen,all important parameter in one page,easy operate.

- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Sico

-

Year:

-

NEW

-

Voltage:

-

380V/3 Phase/50HZ or Custom

-

Dimension(L*W*H):

-

1630*620*1590mm/1780*570*1380mm

-

Hollow part volume:

-

Max 2 Liter

-

Power (kW):

-

16

-

Weight (KG):

-

1000 KG

-

Bottle Volume:

-

50ml-2L

-

Bottle Neck Size:

-

20-80mm

-

Blower Size:

-

1630*620*1590mm

-

Heater Size:

-

1780*570*1380mm

Quick Details

-

Neck Diameter(mm):

-

30 mm

-

Max.Bottle Diameter(mm):

-

110 mm

-

Max.Bottle Height(mm):

-

365 mm

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Sico

-

Year:

-

NEW

-

Voltage:

-

380V/3 Phase/50HZ or Custom

-

Dimension(L*W*H):

-

1630*620*1590mm/1780*570*1380mm

-

Hollow part volume:

-

Max 2 Liter

-

Power (kW):

-

16

-

Weight (KG):

-

1000 KG

-

Bottle Volume:

-

50ml-2L

-

Bottle Neck Size:

-

20-80mm

-

Blower Size:

-

1630*620*1590mm

-

Heater Size:

-

1780*570*1380mm

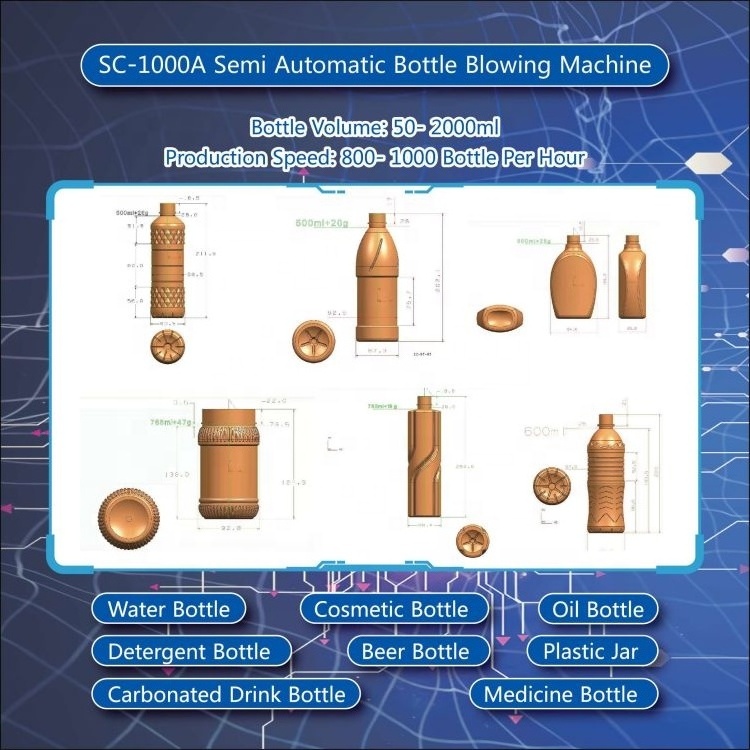

Product Overview

Technical Parameter

|

Model

|

SC-1000A Semi Automatic PET Bottle Blowing Machine

|

|

|

|

Theoretical output

|

800--1000 pcs/h

|

|

|

|

Finished bottle

|

Max. bottle volume

|

50-2000ml

|

|

|

|

Neck diameter

|

20-80mm

|

|

|

|

Max. bottle diameter

|

110mm

|

|

|

|

Max. bottle height

|

365mm

|

|

|

Mold specifications

|

Cavity

|

2 cavity

|

|

|

|

Mold thickness

|

110mm-230mm

|

|

|

|

Open stroke

|

180mm

|

|

|

Electrical system

|

Power voltage

|

380v/3Phase/50HZ

|

|

|

|

Installation power

|

16kw

|

|

|

|

Actual power consumption

|

5kw

|

|

|

Air source

|

Recommend air compressor

|

1.2m³/min 30Kg

|

|

|

Cooling water

|

Recommend water chiller

|

5HP

|

|

|

Blowing machine size

|

Length*width*height/weight

|

1630*620*1590mm/750kg

|

|

|

Auto Loader size

|

Length*width*height/weight

|

1780*570*1380mm/250kg

|

|

Our Advantage

|

Components

|

Brand

|

|

PLC

|

Xinje

|

|

Touch Screen

|

Xinje

|

|

Cylinder

|

Yongcheng

|

|

Blowing Valve

|

Sinopc

|

|

Action valve

|

Festo

|

|

Circuit Breaker

|

Schneider

|

1. Working area equipped with lighting.

2. Anti-pinch device to ensure safe production.

2. Anti-pinch device to ensure safe production.

2. Equip with air cooling and water cooling.

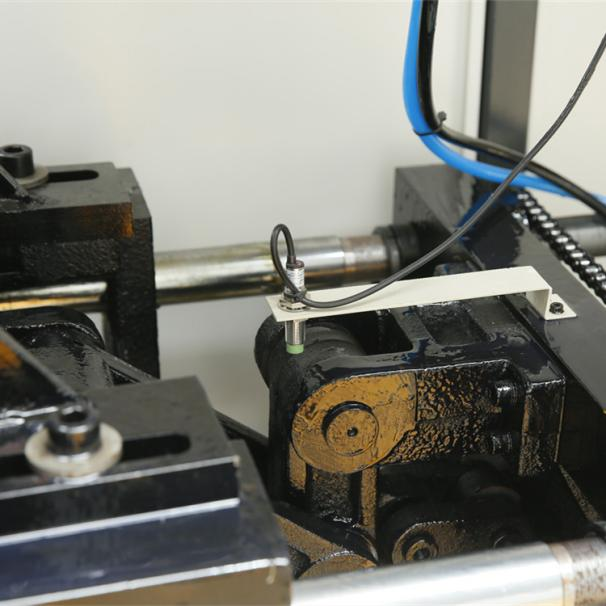

1. Each cavity 3 pieces high quality blowing valve,with big and strong metal silencer.

2. Blowing and exhaust independently valve,blowing speed fast,prolong the life of components.

3. Equipped with Pre-blow,easy debug.

1. Equip with Airtac lubricator,prolong machine pneumatic parts life.

2. Equip with special manual exhaust valve,easy exhaust air when change mold.

2. Equip with special manual exhaust valve,easy exhaust air when change mold.

Certification And Test Report

FAQ

Q: How can we get this machine ?

A:

Please contact us check the details and bottle design before we start it.

We will make ONLINE ORDER and start production for you.

Q: Do you have engineer available to our factory help us install machine?

A:

Yes,we have engineer allowed to visit all safety country to help you install machine and train employees.

Also we have online engineer who will guide you how to install machine and debug.

Q: Can we custom made the machine?

A:

Yes,we support custom made.

Machine color,machine important parts brand all support custom.

Also we support add mutiple languages to the machine operation panel

,including Chinese,English,Arabic,Spanish, Russian......

Hot Searches