- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

+-1mm

-

Voltage:

-

220V/110V/50Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

xinyou

-

Dimension(L*W*H):

-

850*750W*1905(mm)

-

Weight:

-

80 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support, Free spare parts

-

Nozzles:

-

12pcs

-

Hopper:

-

20L

-

Filling speed:

-

7-13 seconds/mould

-

Controll system:

-

PLC

-

Material:

-

SUS304

-

Filling range:

-

1-14ml lipstick

-

Certification:

-

ce

Quick Details

-

Machinery Capacity:

-

4000BPH, 400BPH, 1000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

LIPSTICK, Lips gloss, cream, lotion

-

Filling Accuracy:

-

+-1mm

-

Voltage:

-

220V/110V/50Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

xinyou

-

Dimension(L*W*H):

-

850*750W*1905(mm)

-

Weight:

-

80 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support, Free spare parts

-

Nozzles:

-

12pcs

-

Hopper:

-

20L

-

Filling speed:

-

7-13 seconds/mould

-

Controll system:

-

PLC

-

Material:

-

SUS304

-

Filling range:

-

1-14ml lipstick

-

Certification:

-

ce

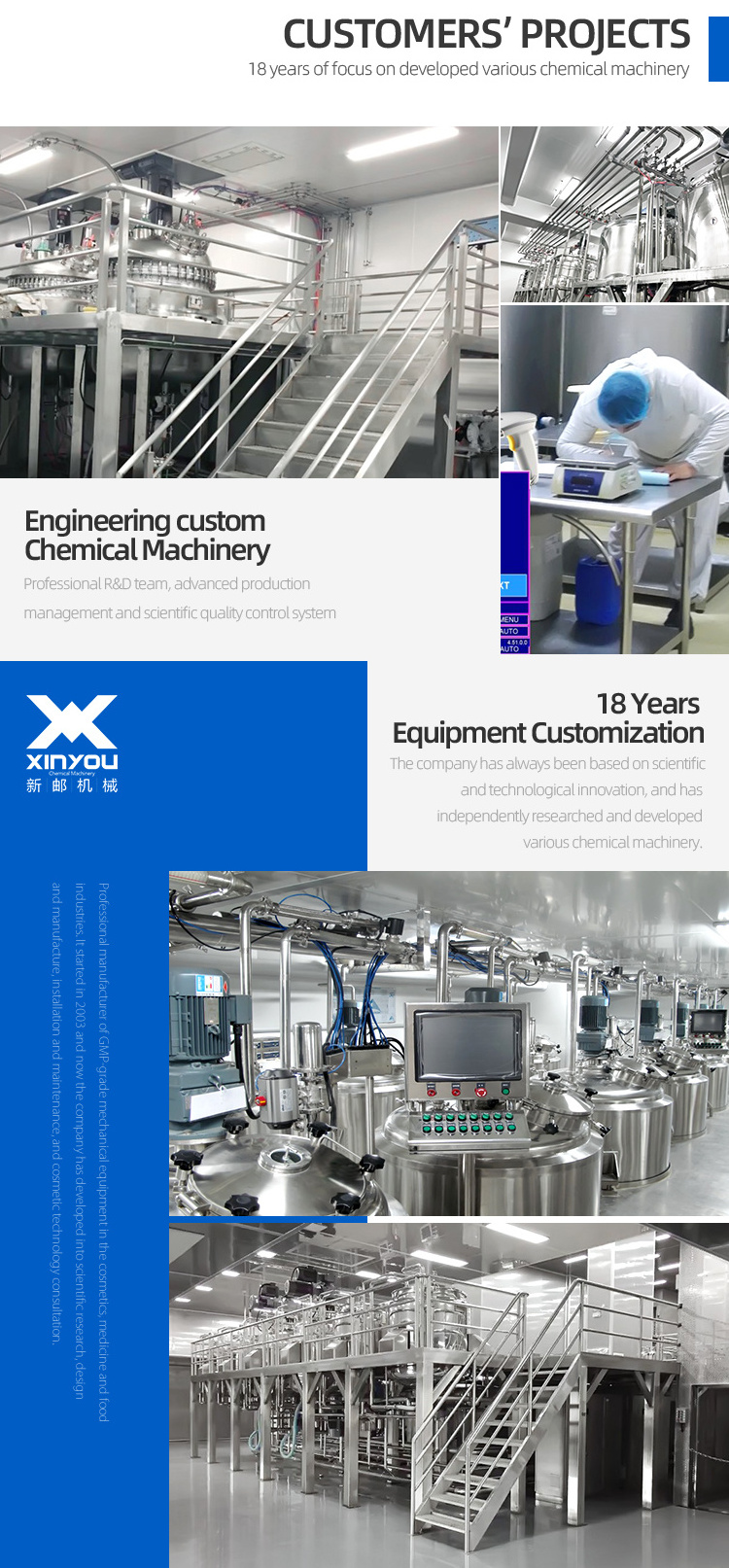

This machine can be used to fill a wide range, many types of lipstick.

Large plastic pens, fine-shaped lipstick, Lip balm ... even if the raw materials containing glitter, pearl powder can also charge to fill.

1.Stirring speed and temperature of each tank are controlled independently

2.Adopted advanced automatic control technology,(interface, PLC,

network),parameter(time,temperature,switch and speed of conveyor)is set by human machine interface,easy control and stable

performance.

3.Framework made of hardened aluminum, easy to maintain.

4.It doesn't need much time to train operator

5.Individual temperature control by PLC for separate unit(tank,filling pump,filling hoes,filling nozzle and heating plate) to achieve precise temperature

6.Automatic timer and counter

7.And available with conveyor

Large plastic pens, fine-shaped lipstick, Lip balm ... even if the raw materials containing glitter, pearl powder can also charge to fill.

1.Stirring speed and temperature of each tank are controlled independently

2.Adopted advanced automatic control technology,(interface, PLC,

network),parameter(time,temperature,switch and speed of conveyor)is set by human machine interface,easy control and stable

performance.

3.Framework made of hardened aluminum, easy to maintain.

4.It doesn't need much time to train operator

5.Individual temperature control by PLC for separate unit(tank,filling pump,filling hoes,filling nozzle and heating plate) to achieve precise temperature

6.Automatic timer and counter

7.And available with conveyor

Product Categories

Exhibition

Certifications

FAQ

Q1. Why choose us ? Are you a Factory?

A1. We have our own factory and skilled workers, rich-experienced R&D and professional service team.

Q2. How long is your delivery time?

A2. Generally it is 15-30 days.

Q3. I want to set a production line, can you provide a whole line packing machinery?

A3. We are professional in packing machinery and we can provide such whole line machinery like cream/Toothpaste/Soap/Liquid Products/Make Up Products/Powder Filling packing line.

Q4. Do you have one year guarantee for the machines?

A4. Sure! We Guarantee one year for the machines, if the machines goes wrong in guarantee and wasn't caused by improperly operation we will offer the new parts for free.

Q5. How about the after service?

A5. There’s no problem we could send our engineer to install or fix the machine locally in due course but customer need to pay the round air tickets cost and arrange the hotel accommodation for our engineer.

Hot Searches