- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

anti vibration rubber mount

-

Product name:

-

anti vibration rubber mount

-

Material:

-

NR,NBR,EDPM.ect.

-

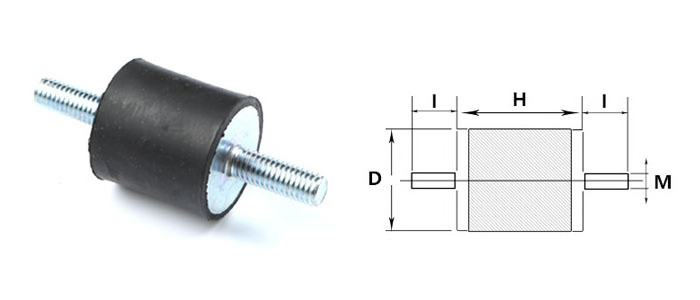

Size:

-

D35*H35*M8*12 MM

-

Shape:

-

Cylindrical

-

Usage:

-

Industrial Shock Absorber

-

Function:

-

Shock Absorption

-

Drawing Format:

-

3D/CAD/2D or photo

-

Structure:

-

rubber and metal parts

-

Model number:

-

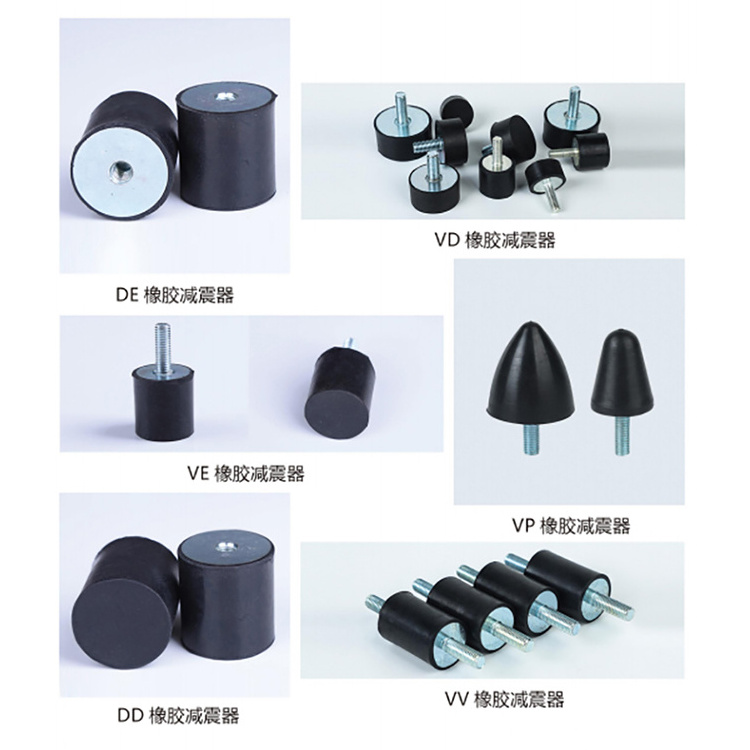

VV,VD,VE,DD,DE

-

Feature:

-

Durable

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dingcheng

-

Model Number:

-

anti vibration rubber mount

-

Product name:

-

anti vibration rubber mount

-

Material:

-

NR,NBR,EDPM.ect.

-

Size:

-

D35*H35*M8*12 MM

-

Shape:

-

Cylindrical

-

Usage:

-

Industrial Shock Absorber

-

Function:

-

Shock Absorption

-

Drawing Format:

-

3D/CAD/2D or photo

-

Structure:

-

rubber and metal parts

-

Model number:

-

VV,VD,VE,DD,DE

-

Feature:

-

Durable

Factory Direct Supply Vibration Isolators cheap quality anti vibration rubber mount Rubber Buffer

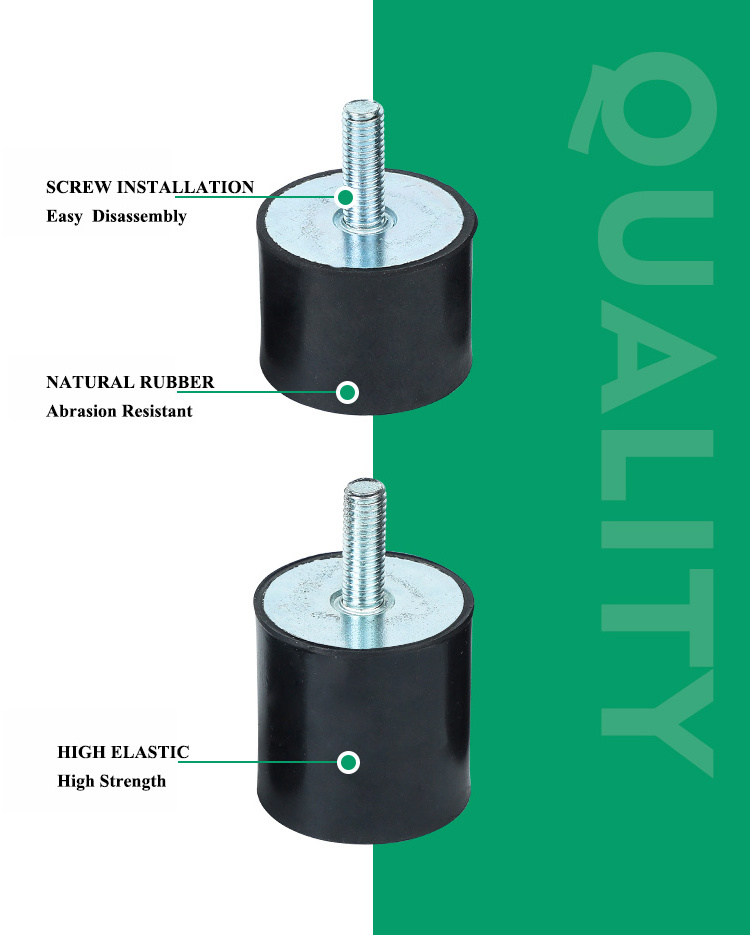

Anti Vibration Rubber Mount is a rubber-metal sleeve designed to absorb and eliminate vibrations and shocks caused by vibrations of mechanical elements, e.g. in the suspension, while driving a car.

|

Item |

Specification |

|

Anti Vibration Rubber Mount |

Also called silent block, rubber mounts, rubber damper block, rubber shock absorber etc |

|

Metalwork |

Mild steel, plated |

|

Structure |

Natural rubber, bonded, cylindrically shaped. |

|

Welded fixings |

3 styles (single side threaded stud, single side threaded hole, double threaded stud, double threaded hole, combination fixing). |

Structure & Working Principle of Anti Vibration Rubber Mount

The Anti Vibration Rubber Mount consists of a metal structure made of two sleeves inserted into each other. Between the sleeves there is an elastic part (rubber element) responsible for dampening vibrations and absorbing vibrations.

The finished product consists of two connected sleeves with a rubber bonded between them. Natural or synthetic rubber is injected into the gap between the two bushings to fill the void between them. Then the rubber is vulcanized. Vulcanization (cross-linking process) is one of the steps in the formation of rubber-metal sleeves, resulting in a flexible rubber that exhibits better resistance to abrasion or temperature fluctuations. Then, the silenblocks are pre-compressed, which increases their dynamic strength and service life. There are also offers on the market for sleeves made of polyurethane, the price of which differs from rubber-metal elements.

Support Customized Order

Provide drawing with 3D/CAD/2D or photo , even your manuscripts also ok.

Application of Anti Vibration Rubber Mount

Anti Vibration Rubber Mount is a rubber combined with a metal insulator, thanks to which you can reduce vibrations. It is mainly used for:

- connecting parts of the car suspension

- leveling vibrations transferred from one element to another

- installation in various vehicle systems (engine, gearbox, shock absorbers)

- mitigating vibrations of internal fans, washing machines, cylinders, motors

- leveling the transmission of vibrations to the outside

- easing and resolving loads occurring in vibrating and oscillating systems

They are used in suspension systems in the automotive industry (suspensions for passenger cars and vans, agricultural machinery, trailers, motorcycles). Their price depends on the material they are made of, as well as their diameter and length. These rubber-metal joints are highly flexible and will be used not only in car suspensions, but also in household appliances and machines.