- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Walker/JXSC

-

Weight:

-

9500 KG

Product Introduction

Impact crushers for hard rock are the newest generation of impact crushers developed by our factory by absorbing advanced technology at home and abroad and according to actual working conditions in domestic sand industry. Such equipment enjoy advantages such as big crushing ratio, the shape of cubic particles of materials after crushing, and long service life of wear-resistant parts. Users of it gain considerable economic benefits.

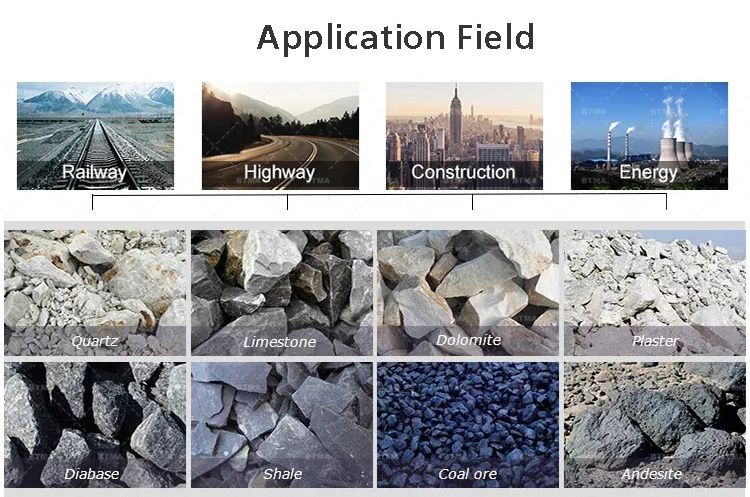

The impact crusher is widely used in quarrying, concrete recovery and mining. It can be used in primary, secondary, or tertiary applications. It can break medium hard rock, such as granite, cobble, limestone, quartz, coal mine and other materials. Processing capacity (T/h): 30-500, maximum feed (mm): 300-700.

Suitable Material

Pebble,granite, iron ore, limestone, quartz, diabase, concrete etc.

Performance characteristics of our products

1. An ovel structure, unique, stable operation, multi cavity uniform broken,suitable for crushing hard rock. 2. Low energy consumption, high yield, high crushing ratio, for general 10-20, high up to 50-60. 3. With the shaping function, product is cubic shape, high packing density, adjustable dischargesize, simplified crushing process. 4. All the whole plate structure to discharge is small size and cubic, no inner crack. 5. Feeding port is low and big, easy to arrange production line and increase the feed size. 6. Impact crusher use of new wear-resistant material, so the plate hammer, impact plate and lining board has longer service life. 7. Easy to use and repair, can be used as selective crushing. 8. Unique tooth type impact lining board, especially suitable for crushing hard rock,high efficiency and energy saving.

Product Details

|

Model

|

Rotor Spec (mm)

|

Feed opening size (mm)

|

Max

Feededge(mm)

|

Capacity (t/h)

|

Motor Power(kw)

|

Weight(t)

|

Overall Dimension(L*W*H)mm

|

|

PF-1007

|

1000*700

|

400*730

|

300

|

30-50

|

37-55

|

9.5

|

2400×1558×2660

|

|

PF-1010

|

1000*1050

|

400*1080

|

350

|

50-80

|

55-75

|

12.2

|

2400×2250×2620

|

|

PF-1210

|

1250*1050

|

400*1080

|

350

|

70-120

|

110-132

|

14.9

|

2690×2338×2890

|

|

PF-1214

|

1250*1400

|

400*1430

|

350

|

110-180

|

132-160

|

18.6

|

2690×2688×2890

|

|

PF-1315

|

1320*1500

|

860*1520

|

500

|

160-250

|

180-260

|

19.3

|

3096×3273×2667

|

|

PF-1320

|

1320*2000

|

860*2030

|

500

|

160-350

|

300-375

|

28

|

3096×3560×3185

|

|

PF-1520

|

1500*2000

|

1315*2040

|

700

|

300-500

|

400-450

|

42.8

|

3890×3560×3220

|

Southeast Asia Impact Crusher Machine

Nigeria Impact Stone Crusher

Africa Impact Crusher Liner

Zambia Impact Crusher PF 1210

Congo Vertical Shaft Impact Crusher

Mozambique Impact Cone Crusher

◆ Ways of packing

◆ Shiping by sea/air freight

Jiangxi walker Machinery Co.,Ltd, are a professional manufacturer of complete set mining equipments, a sub-company of JXSC mine machinery factory in Jiangxi province.professional at providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore / Diamond/ Coltan ore / Silica sand / Zircon sand/ Black sand/Chrome ore, ect. As well as complete set small lab mining machines.

Our core advantages as below:

1.+30years history factory at mining machinery

2.Provide engineer team after sale service

3.Provide complete set mineral processing plant

4.Provide sample testing service in factory lab for free

5.Provide professional ming soolution consulting

*Ore sample testing support

*View our Factory

*Design Flowchart