2.It also suitble for paper mill, textile, slaughter, food, starch, chemicals etc.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

194-5230 Kgs

-

Size:

-

L1816*W750*H1040-L4600*W2250*H1960

-

Power:

-

0.35-8.2 KW

-

Productivity:

-

other

-

Weight (KG):

-

3000 kg

-

Product name:

-

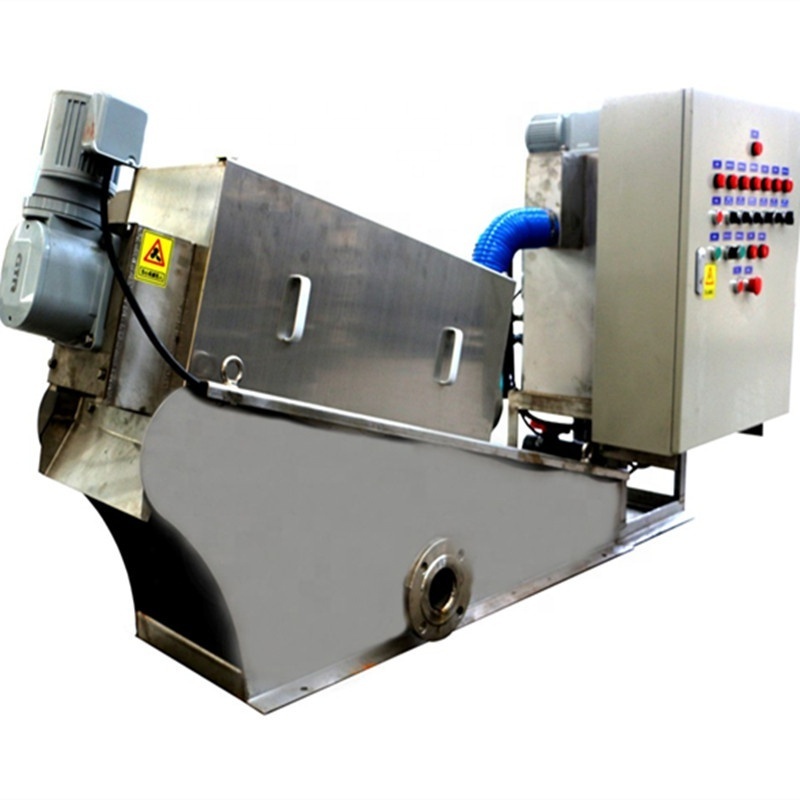

Volute Sludge Dewatering Machine

-

Certification:

-

ISO9001,

-

Voltage:

-

220V/ 380V

-

Color:

-

Customized

-

Control:

-

Automatic Control Box

-

MOQ:

-

1 Set

-

Function:

-

Sludge Dewatering

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BETTER

-

Material:

-

ss/cs, Carbon Steel/Stainless steel

-

Weight:

-

194-5230 Kgs

-

Size:

-

L1816*W750*H1040-L4600*W2250*H1960

-

Power:

-

0.35-8.2 KW

-

Productivity:

-

other

-

Weight (KG):

-

3000 kg

-

Product name:

-

Volute Sludge Dewatering Machine

-

Certification:

-

ISO9001,

-

Voltage:

-

220V/ 380V

-

Color:

-

Customized

-

Control:

-

Automatic Control Box

-

MOQ:

-

1 Set

-

Function:

-

Sludge Dewatering

Product Description

|

Model

|

Dimensions(L*W*H mm)

|

Power(kw)

|

Weight(kg)

|

|

BEA-131

|

1816*750*1040

|

0.35

|

194

|

|

BEA-132

|

2065*900*1040

|

0.45

|

275

|

|

BEA-201

|

2500*680*1450

|

0.74

|

380

|

|

BEA-202

|

2500*930*1450

|

1.1

|

470

|

|

BEA-301

|

3200*970*1790

|

0.92

|

820

|

|

BEA-302

|

3600*1200*1790

|

1.65

|

1350

|

|

BEA-303

|

3850*1600*1790

|

2.2

|

1820

|

|

BEA-351

|

4000*750*2000

|

1.3

|

950

|

|

BEA-352

|

4200*1200*2000

|

2.25

|

1300

|

|

BEA-353

|

4350*1700*2000

|

3.35

|

1680

|

|

BEA-401

|

4200*850*2100

|

2.05

|

1270

|

|

BEA-402

|

4350*1450*2100

|

3.75

|

2350

|

Product Characteristic:

1.Non-clogging design, 24h running automatically.

2.Self-cleaning, little rinsing water.

3.Low-concentrated sludge handling.

4.Energy saving. Saving power, 1/20 of centrifugal.Saving water, 1/8 of belt press.

5.All-in-one design, save construction cost.

6.Low maintenance cost.

7.Low noise and little vibration.

2.Self-cleaning, little rinsing water.

3.Low-concentrated sludge handling.

4.Energy saving. Saving power, 1/20 of centrifugal.Saving water, 1/8 of belt press.

5.All-in-one design, save construction cost.

6.Low maintenance cost.

7.Low noise and little vibration.

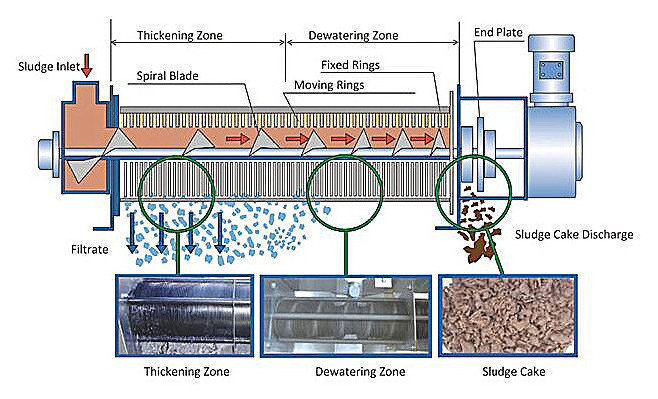

Working principle:

The wastewater is pushed into the dewatering machine.The sludge will move to the sludge cake outlet under the pressure of the helical aixs blades. Becuse the gap among the helical blades become narrower,so the sludge bear heavier pressure and began to dewatering under the pressure. The water comes out from the space between fixed and moving plates.

The wastewater is pushed into the dewatering machine.The sludge will move to the sludge cake outlet under the pressure of the helical aixs blades. Becuse the gap among the helical blades become narrower,so the sludge bear heavier pressure and began to dewatering under the pressure. The water comes out from the space between fixed and moving plates.

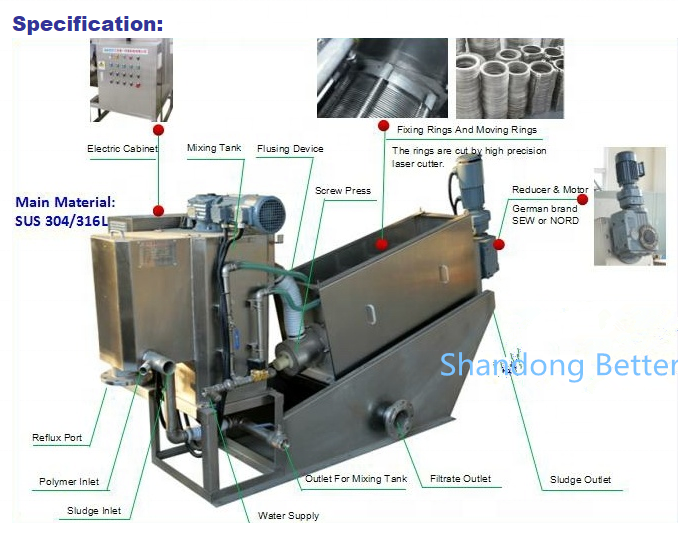

Product Description:

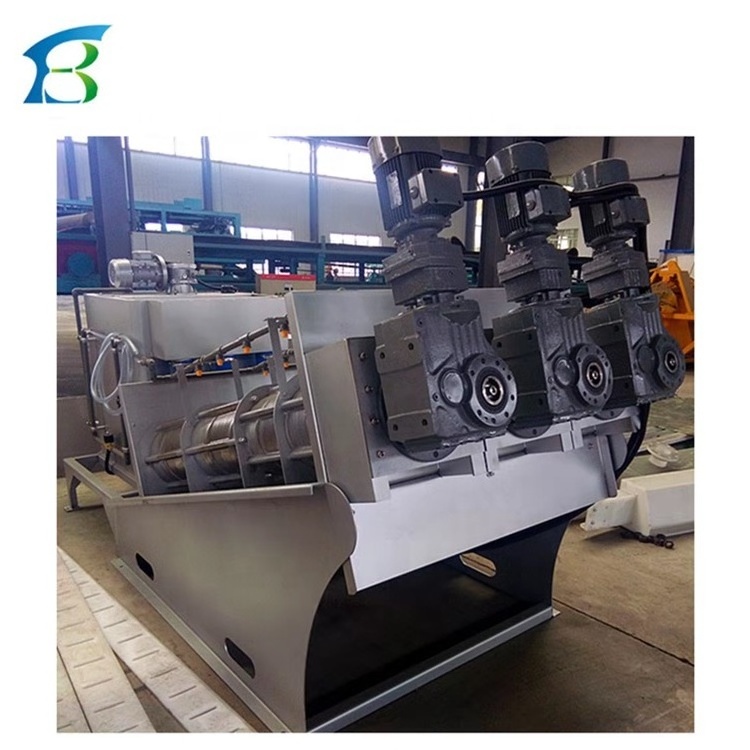

The main body ofScrew Press Separator For Sludge Dewatering consists of both thicken stage and dewatering stage. The screw axis is inside the middle of the machine, the thicken and dewatering stage are formed by fixed ring and moving ring respectivey, equipped with automatic cleaning system. When dewatering, the moving ring will clean the gap timely under the impelling of screw axis, to avoid blocking; and meantime save cleaninf water and largely guarantee of continuously and stable of plant operation

Volute Sludge Dewatering Machine belongs to the screw press, it's clog-free and can reduce the sedimentation tank and sludge thickening tank, saving the cost of sewage plant construction. it using screw and the moving rings to clean itself as clog-free structure, and controlled by the PLC automatically, it's a new technology that can replace the traditional filter press like belt press and frame press, the screw speed is very low, so it cost low power and water consumption in contrast to the centrifuge, it is a cutting edge sludge dewatering machine.

Volute Sludge Dewatering Machine belongs to the screw press, it's clog-free and can reduce the sedimentation tank and sludge thickening tank, saving the cost of sewage plant construction. it using screw and the moving rings to clean itself as clog-free structure, and controlled by the PLC automatically, it's a new technology that can replace the traditional filter press like belt press and frame press, the screw speed is very low, so it cost low power and water consumption in contrast to the centrifuge, it is a cutting edge sludge dewatering machine.

The main body of volute sludge dewatering machine consists of both thicken stage and dewatering stage. The screw axis is inside the middle of the machine, the thicken and dewatering stage are formed by fixed ring and moving ring respectivey, equipped with automatic cleaning system. When dewatering, the moving ring will clean the gap timely under the impelling of screw axis, to avoid blocking; and meantime save cleaninf water and largely guarantee of continuously and stable of plant operation.

Application

2.It also suitble for paper mill, textile, slaughter, food, starch, chemicals etc.

-

Characteristics

2. large handling capacity

3. save cleaning water

4. continuous and stable operation

After Sales Service

2.Field installation

3.Commissioning and training

4.Field maintenance and repair service

5.Video technical support

Main Products

Project Case

Certifications

Hot Searches