- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OKS

-

Power:

-

300W-7000W

-

Weight (KG):

-

180 kg

-

Frequency:

-

25KHZ or 28KHZ or 33KHZ or 40KHZ

-

Product name:

-

Tubular Ultrasonic Transducer

-

Application:

-

Industrial Parts Cleaning

-

Function:

-

Industrail Auto Parts Ultrasonic Cleaning

-

Usage:

-

Hardware Part/Cleaning Car Radiator/Filter Oil

-

Ultrasonic Power:

-

7000W adjustable

-

Size:

-

Can Be Custom Made

-

Voltage:

-

110V-120V / 220V-240V

-

Transducer Quantity:

-

6-70Pcs

Quick Details

-

Marketing Type:

-

High Efficient Cleaning

-

Core Components:

-

Generator

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

OKS

-

Power:

-

300W-7000W

-

Weight (KG):

-

180 kg

-

Frequency:

-

25KHZ or 28KHZ or 33KHZ or 40KHZ

-

Product name:

-

Tubular Ultrasonic Transducer

-

Application:

-

Industrial Parts Cleaning

-

Function:

-

Industrail Auto Parts Ultrasonic Cleaning

-

Usage:

-

Hardware Part/Cleaning Car Radiator/Filter Oil

-

Ultrasonic Power:

-

7000W adjustable

-

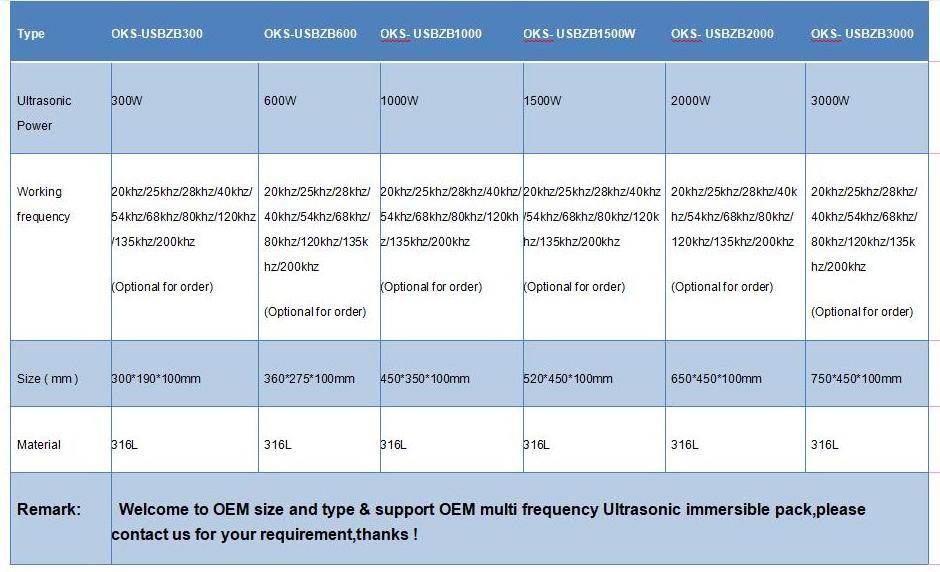

Size:

-

Can Be Custom Made

-

Voltage:

-

110V-120V / 220V-240V

-

Transducer Quantity:

-

6-70Pcs

Title goes here.

28K OR 40KHZ Stainless Steel Tubular Ultrasonic Transducer 300W-7000W Submersible Ultrasonic Vibration Rod

Products Description

The ultrasonic vibration plate is also called an ultrasonic vibration box or an ultrasonic cleaning box, which is an ultrasonic

cleaning device composed of an ultrasonic vibrator bonded and sealed in a stainless steel box and an ultrasonic generator.

Generally placed in various cleaning tanks to achieve the purpose of ultrasonic cleaning. The size of the vibration plate and the

direction of the lead tube can be made into three types: bottom vibration type, side vibration type and top vibration type

according to different installation positions, to achieve a thorough cleaning effect according to different usage requirements.

Suitable for electronic parts, electroplating hardware, auto parts, optical lenses, jewelry, glassware, filter elements,

spinnerets, medical equipment, etc.

The working principle of the ultrasonic vibration box is that the ultrasonic generator generates super audio frequency higher than

20KHZ, which is converted into the same frequency mechanical vibration into the cleaning liquid through the transducer. Bubbles

form and grow in the negative pressure zone where the ultrasonic wave propagates longitudinally, and burst rapidly in the positive

pressure zone. The formation, growth, and rapid collapse of such tiny bubbles is called the "cavitation effect". In the cavitation

effect, an instantaneous high pressure of more than 10,000 atmospheres is generated after the bubble bursts. The continuously

generated instantaneous high pressure is like a series of small explosions that continuously bombard the surface of the object,

causing the surface of the object to quickly fall off the dirt.

Ultrasonic vibration boxes are widely used in electronic devices, semiconductor wafers, circuit boards, electroplated parts,

optical lenses, chemical fiber spinnerets, spinnerets, latex tools, magnetic materials, glassware, communication equipment,

hydraulic parts, hardware tools, bearings , Oil nozzle, oil pump, carburetor, locomotive parts, degreasing, derusting,

decarbonizing and surface treatment, especially for deep holes, blind holes, concave-convex groove cleaning is ideal equipment.

cleaning device composed of an ultrasonic vibrator bonded and sealed in a stainless steel box and an ultrasonic generator.

Generally placed in various cleaning tanks to achieve the purpose of ultrasonic cleaning. The size of the vibration plate and the

direction of the lead tube can be made into three types: bottom vibration type, side vibration type and top vibration type

according to different installation positions, to achieve a thorough cleaning effect according to different usage requirements.

Suitable for electronic parts, electroplating hardware, auto parts, optical lenses, jewelry, glassware, filter elements,

spinnerets, medical equipment, etc.

The working principle of the ultrasonic vibration box is that the ultrasonic generator generates super audio frequency higher than

20KHZ, which is converted into the same frequency mechanical vibration into the cleaning liquid through the transducer. Bubbles

form and grow in the negative pressure zone where the ultrasonic wave propagates longitudinally, and burst rapidly in the positive

pressure zone. The formation, growth, and rapid collapse of such tiny bubbles is called the "cavitation effect". In the cavitation

effect, an instantaneous high pressure of more than 10,000 atmospheres is generated after the bubble bursts. The continuously

generated instantaneous high pressure is like a series of small explosions that continuously bombard the surface of the object,

causing the surface of the object to quickly fall off the dirt.

Ultrasonic vibration boxes are widely used in electronic devices, semiconductor wafers, circuit boards, electroplated parts,

optical lenses, chemical fiber spinnerets, spinnerets, latex tools, magnetic materials, glassware, communication equipment,

hydraulic parts, hardware tools, bearings , Oil nozzle, oil pump, carburetor, locomotive parts, degreasing, derusting,

decarbonizing and surface treatment, especially for deep holes, blind holes, concave-convex groove cleaning is ideal equipment.

Product packaging

Certifications

Hot Searches