- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customer Request

-

Weight:

-

500 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V

-

Power:

-

5.5KW

-

Key Machines:

-

Motor,Gear,Engine

-

Product name:

-

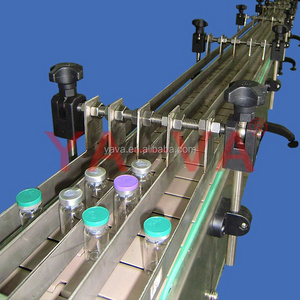

Belt Conveyor Machine

-

Keyword:

-

Transfer Conveyor

-

Structure:

-

Inclining Conveyor

-

Application:

-

stone, cement, corn, coal

-

Feature:

-

Automated Production Line

-

Control System:

-

Electric Control Systrm

-

Length:

-

Customized

-

After-sales Service Provided:

-

Engineers Guide

-

Certification:

-

IOS

-

Install:

-

Engineer's Guide

Quick Details

-

Machinery Capacity:

-

655-1284t/h

-

Brand Name:

-

HAOLU

-

Year:

-

Product 2023

-

Dimension(L*W*H):

-

Customer Request

-

Weight:

-

500 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V

-

Power:

-

5.5KW

-

Key Machines:

-

Motor,Gear,Engine

-

Product name:

-

Belt Conveyor Machine

-

Keyword:

-

Transfer Conveyor

-

Structure:

-

Inclining Conveyor

-

Application:

-

stone, cement, corn, coal

-

Feature:

-

Automated Production Line

-

Control System:

-

Electric Control Systrm

-

Length:

-

Customized

-

After-sales Service Provided:

-

Engineers Guide

-

Certification:

-

IOS

-

Install:

-

Engineer's Guide

NO.1 Product Description

Belt conveyor is widely used in household appliances, electronics, electrical appliances, machinery, tobacco, injection molding, posts and telecommunications, printing, food, and other industries, such as the assembly, testing, debugging, packaging and transportation of objects. The belt conveyor has the advantages of strong conveying capacity, long conveying distance, simple structure, easy maintenance, convenient programmed control, and automatic operation. Widely used in metallurgy, coal, transportation, hydropower, chemical industry, and other departments, because it has the advantages of large capacity, simple structure, convenient maintenance, low cost, strong versatility and so on. At the same time, it is also used in building materials, electric power, light industry, grain, port, shipping, and other departments.

NO.2 Product Application

1, Our belt conveyor is widely used in mining, metallurgy, and the coal industry to transfer all kinds of materials in order to realize the continuity and automation of production.

2, The conveying system can be one single or multi-conveyors or combined with other conveying equipment to meet various requirements.

3, The belt conveyor can be installed horizontally or aslope to meet the needs of different conveying lines.

4, Our belt conveyor can be operated in the circumstance temperature from -20 degrees to +40 degrees. The temperature of the transported materials should be lower than 50 degrees.

NO.3 Working Principle

A Belt conveyor is a common means of transport used in mining enterprises. It uses the belt conveyance to draw and support components and transport materials by way of the moving belt. It utilizes the inner friction and side pressure of loose material to increase the internal pressure from the pulling force in its moving direction produced by the rolling chamber in the adhesive chamber, thus increasing the internal friction. When inclination falls within a certain scope, the inward friction force can ensure stability between layers and create continuous movement. When the internal friction force between the layers is larger than the external force of the adhesive, the roller beneath the adhesive will move along with the material. When the ratio of internal force and external force meets a condition, the material flow is stable.

NO.4 Main Technical Parameters

|

Belt Width

|

Transport Length (m) / Power(kw)

|

|

|

Transportation Speed(m/s)

|

Throughput(t/h)

|

|||||

|

400

|

≤103

|

12-15

3-4 |

15-30

4-7.5 |

1.25-2.0

|

30-60

|

|||||

|

500

|

≤103

|

12-15

4-5.5 |

15-30

5.5-7.5 |

1.25-2.0

|

40-80

|

|||||

|

650

|

≤104

|

12-15

7.5 |

15-30

7.5-11 |

1.25-2.0

|

80-120

|

|||||

|

800

|

≤104

|

12-15

7.5 |

15-30

7.5-15 |

1.25-2.0

|

120-200

|

|||||

|

1000

|

≤105.5

|

10-20

7.5-11 |

20-40

11-22 |

1.25-2.0

|

200-320

|

|||||

|

1200

|

≤107.5

|

10-20

7.5-15 |

20-40

15-30 |

1.25-2.0

|

290-480

|

|||||

|

1400

|

≤1011

|

10-20

15-22 |

<20-40

22-45 |

1.25-2.0

|

400-680

|

|||||

|

1600

|

≤1015

|

10-20

22-30 |

<20-50

30-75 |

1.25-2.0

|

600-1080

|

|||||

|

1800

|

≤1018.5

|

10-20

30-45 |

<20-50

45-110 |

1.0-2.0

|

200-1500

|

|||||

|

2000

|

≤1022

|

10-20

45-55 |

<20-40

55-132 |

1.0-2.0

|

1000-2000

|

|||||

|

2400

|

≤1030

|

10-20

55-75 |

<20-40

75-185 |

1.0-2.0

|

1500-3000

|

|||||

|

The above data are for reference only and are subject to specific conditions.

|

|

|

|

|

|

|||||

NO.5 Main Features

1, Conveying Material Variety

Can transport a variety of bulk materials, a variety of cartons, bags and other single weight of small goods, a wide range of uses;

2, Conveyor Belt Material is Optional

Rubber, canvas, PVC, PU and other materials, in addition to the transport of ordinary materials

3, The Structure is Diverse, Can add Accessories

There are trough belt conveyor, flat belt conveyor, climbing type, tilting, turning belt conveyor and other forms

4, Smooth Delivery, Reduce Damage to Goods

There is no relative movement between the material and the conveyor belt, which can avoid damage to the conveyor belt

5. Less Noise

It is suitable for quiet working environment

6, Simple Structure, Easy to Maintain

Simple structure, easy maintenance, less energy consumption, low cost

Hot Searches