- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Liaoning, China

-

After-sales Service Provided:

-

Online support

-

Feeding width(optional):

-

600/914/1000/1250

-

Coil:

-

0.8 -1.5 mm

-

Buildings:

-

multiple steel building

-

Span:

-

wide range according to model

-

Volt:

-

220/380/440V

-

Power:

-

20-30 KW

-

Shipping:

-

40HQ' or in bulk

-

Color:

-

white or blue

-

sanxing K Q span:

-

one stage machine which is more cost effective

-

Certification:

-

CE

Quick Details

-

Type:

-

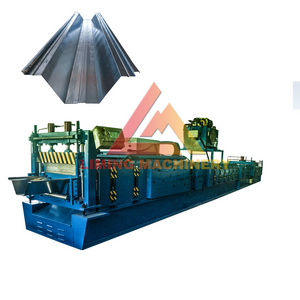

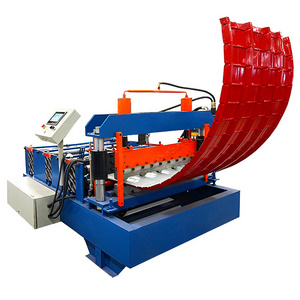

Arching Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

15 m/min

-

Place of Origin:

-

Liaoning, China

-

After-sales Service Provided:

-

Online support

-

Feeding width(optional):

-

600/914/1000/1250

-

Coil:

-

0.8 -1.5 mm

-

Buildings:

-

multiple steel building

-

Span:

-

wide range according to model

-

Volt:

-

220/380/440V

-

Power:

-

20-30 KW

-

Shipping:

-

40HQ' or in bulk

-

Color:

-

white or blue

-

sanxing K Q span:

-

one stage machine which is more cost effective

-

Certification:

-

CE

company information:

Yingkou Samsung Roll Forming Machine Co., Ltd. is the first company in China to produce drag chain roofing machines since 1992. The only company with engineering qualifications. We are not only a mechanical professional, but also have project design experience.

technology:

The steel storage produced by the production line and silo manufacturing machines is connected to several steel plates, which will replace the traditional welding method. Easy maintenance, saving time and cost of installation and production. The silo will have a good seal and a curled five-layer spiral. Steel storage lines and silo manufacturing machines connect the steel very tightly, so that the silo is well tolerated even with chemicals or fumigated products.

process:

The steel will undergo five forming and bending procedures with strips 2 to 4 mm thick and 495 mm wide. It will then be forced to merge and spirally stitch into a 4-50 meter high cylinder of different diameters. Steel storage lines and silo machines also add sealant to the spiral joints for storing liquids and even wastewater.

HIGH SPEED OF CONSTRUCTION

With SUBM Mobile Factory, a 1000-square meter structure can be built in 24 hours. Using the high speed of fabrication and seaming of panels,a crew of 10 to 12 workers can fabricate and erect nearly 100 arched panels in one day.

LOW COST

Due to the above reason, the coast of construction of a SUBM Building is less than that of conventional and prefabricated buildings.

ON-SITE MANUFACTURING

The SUBM Mobile Factory is taken directly to the construction site and the building is fabricated completely on-site. No costs of shipping of building components from a fabrication shop are incurred.

MOBILITY AND ACCESS TO REMOTE AREAS

Our trailer-mounted SUBM Factories can be easily towed by and ordinary vehicle to any remote part of the country and put into operation the moment it arrives at the site without any delay whatsoever.

NO STRUCTURAL COLUMNS, BEAMS OR TRUSSES REQUIRED

The SUBM arches are designed to be totally self-supporting and do not require any support structure such as is needed in standard steel frame buildings.

SAVINGS IN MANPOWER

A crew of approximately 10 to 15 trained men can erect a 1000 square meter building in a single day. You can build your SUBM buildings in either steel or aluminum, pre-painted in an unlimited range of colors. We also stock most of our coils and immediately ship with our unit to the site.

Type two: All hydraulic machine

( Please note that SANXING is the only manufacture that can make the machine in China )

The Advantage of All Hydraulic Type: Work steadily,produce faster and less maintenance.

Model List (please refer to your local situation to select the model)

Yingkou Sanxing Group is located in Yingkou city, Liaoning province, China since 1992. We are a manufacturer which design and manufacture various kinds of cold roll forming machine, we are also a supplier for lots of Chinese trading company and manufacturer.

Our main products include ultimate construction machine, automatic construction machine, screw joint roll forming machine, spiral steel silo roll forming machine, KR standing seam roll forming machine, flat steel sheet roll forming machine, deck floor roll forming machine, sandwich panel roll forming machine, C/Z shape steel purlin roll forming machine, light steel frame roll forming machine, rolling door roll forming machine, etc.

Our products have sold to various countries in the world. We warm welcome customers from all over the world to visit our company.