- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

PK

-

Voltage:

-

as per order

-

Dimension(L*W*H):

-

Customized Size

-

Certification:

-

ISO CE BV

-

Conveyor:

-

Conveyor

-

Inlets and outlets:

-

multible

-

Conveying trough:

-

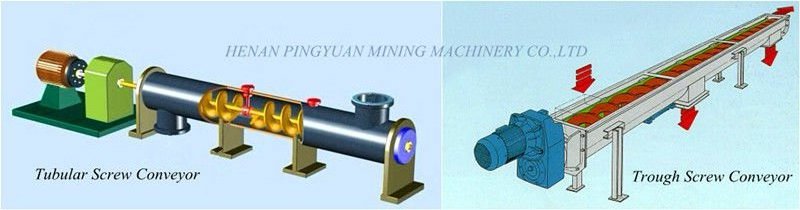

"U" and tubular shape

-

Pollution:

-

No

-

Screw Pitch:

-

160/200/250/300mm

-

Rotating Speed:

-

160/200/260/300rpm

-

Capacity:

-

15~120 m3/h

-

Max.Conveying Distance:

-

25m

-

Screw Diameter:

-

160/200/250/300/370mm

-

Product name:

-

Auger Screw Conveyor

Quick Details

-

Power:

-

Customized

-

Warranty:

-

1 Year

-

Width or Diameter:

-

800mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

PK

-

Voltage:

-

as per order

-

Dimension(L*W*H):

-

Customized Size

-

Certification:

-

ISO CE BV

-

Conveyor:

-

Conveyor

-

Inlets and outlets:

-

multible

-

Conveying trough:

-

"U" and tubular shape

-

Pollution:

-

No

-

Screw Pitch:

-

160/200/250/300mm

-

Rotating Speed:

-

160/200/260/300rpm

-

Capacity:

-

15~120 m3/h

-

Max.Conveying Distance:

-

25m

-

Screw Diameter:

-

160/200/250/300/370mm

-

Product name:

-

Auger Screw Conveyor

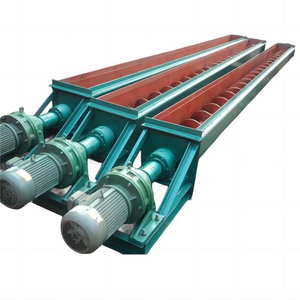

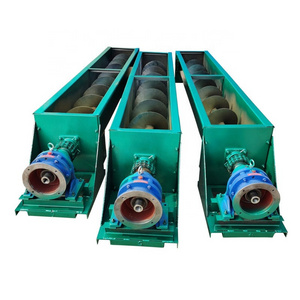

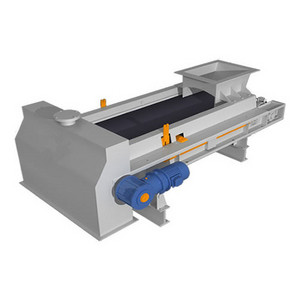

Material Handling Equipment Mining Coal Dust Auger Screw Conveyor for Sale

Material Handling Equipment Mining Coal Dust Auger Screw Conveyor for Sale

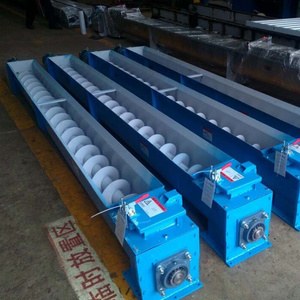

1.No pollution:

Flexible auger machine with totally-enclosed structure without causing any environmental pollution.

2.Widely application:

Construction available in mild steel and stainless steel so flexible auger machine can widely used for all kinds of material

3.Easy to installed:

With simple structure so flexible auger machine easy assembly and replacement of component parts.

4.Easy maintenance and low operating cost.

5.Multiple inlets and outlets.

Flexible auger machine with multiple inlet and outlet,so it can mix material and unload material at any points

Screw Conveyor's Structure

Single shaft Coal Dust Auger Screw Conveyor mainly consists of tube (head/ trail/ hanging bearings, conveying spiral, housing, cover plate and base plate), inlet and outlet chutes, as well as driving device (electric motor, reducer, coupling and base plate).

|

Model |

LSY100 |

LSY120 |

LSY140 |

LSY160 |

LSY200 |

LSY250 |

LSY300 |

LSY400 |

||

|

Metric diameter of screw (mm) |

90 |

115 |

135 |

163 |

185 |

237 |

285 |

362 |

||

|

Rotary speed of main axis (r/min) |

300 |

300 |

300 |

308 |

260 |

200 |

170 |

170 |

||

|

Diameter of main case(mm) |

108 |

133 |

159 |

194 |

219 |

273 |

325 |

402 |

||

|

Max capacity (t/h) |

7 |

10 |

15 |

25 |

40 |

60 |

90 |

120 |

||

|

Max Length of conveying length L (m) |

8 |

10 |

12 |

15 |

18 |

25 |

25 |

25 |

||

|

Working angle (degree) |

0°~60° |

0°~60° |

0°~60° |

0°~60° |

0°~60° |

0°~60° |

0°~60° |

0°~60° |

||

|

Motor |

model |

L≤7M |

Y90S-4 |

Y100L1-4 |

Y100L2-4 |

Y132S-4 |

Y132M-4 |

Y160L-6 |

Y180M-4 |

Y180M-4 |

|

Power(kw) |

1.1 |

2.2 |

3 |

5.5 |

7.5 |

11 |

18.5 |

18.5 |

||

|

model |

L≥7M |

Y100L1-4 |

Y100L2-4 |

Y112M-4 |

Y132M-4 |

Y160M-4 |

Y180L-6 |

Y180L-4 |

Y180L-4 |

|

|

Power( kw) |

2.2 |

3 |

4 |

7.5 |

11 |

15 |

22 |

22 |

||

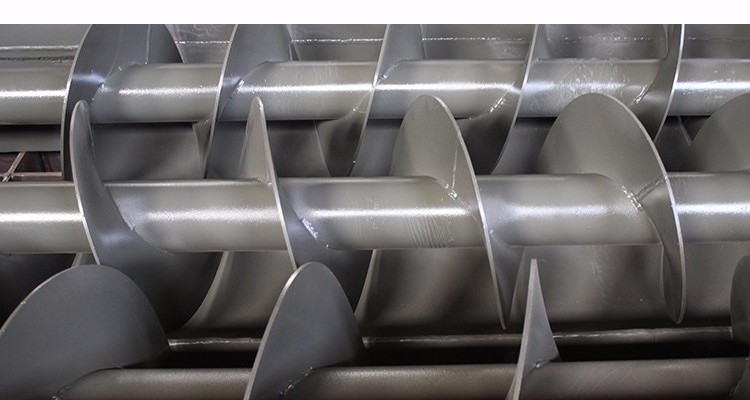

1. Spiral Blade/ Helical Blade

2. Driving Device

Material Handling Equipment Mining Coal Dust Auger Screw Conveyor for Sale

1.We can deliver Auger Screw Conveyor timely .

2.Standard packing or as per customer 's packing instruction .

3.15-30 days after receiving the deposit .

Henan Pingyuan Mining Machinery Co.,Ltd (PKmachinery) had earned many certificates about the whole strength and had cooperated with many group companies in the whole world. There is a systematized program in our company, every order will strictly according to the standard system to show our customer the best immediately.

PK machinery offers a full range of screening and conveying equipment,which involves vibrating screen,belt conveyor,bucket elevator,screw conveyor,scraper conveyor and related spare parts.What's more,PK Machinery is always cooperating with the world-class suppliers to ensure the product's high quality,including ABB,SEW,SIEMENS,etc.

As the saying goes,"there is no diamond,do not get porcelain living."

PK machinery has Sophisticated-equipment and advanced technology.

Up to now,PK machinery has already built the production lines as following: roller production line, pulley production line, automatic cutting production line, welding robots, planer milling, shear plate bending production line, steel pretreatment production line.

1.How long is the delivery time of your equipment?

The delivery time is within 30 working days. But when the project is very big and the customers have special requirement , the delivery could be extended , based on different situations.

2.How long is the equipment warranty period?

Our equipment warranty period is 1 year. Wearing parts and problem coursed by worker’s wrong operation are not included.

3.Can you give me a solution and quotation?

Absolutely sure, we can provide accurate solution and quotation, please give us background information, including, raw material, the capacity, max. input size, the output size, the usage of final products, etc.

4.How could I trust your promise?

A:You may check the qualification on our website certified by the appraisal agency Bureau Veritas;

B:Company inspection always available.Sincerely welcome your visit.

| ♦Material to be processed: _____ | ♦Working environment is indoor or outdoor:________ |

| ♦Handling capacity (Ps. It means the total | ♦Working environment temperature: _______ ℃ |

| material capacity feeding from the inlet): _____t/h | ♦Upstream equipment (Ps. It means what kind of |

| ♦Bulk Density: _____t/m3 | equipment is used to feed the material): _____ |

| ♦Conveying distance(distance between | ♦Downstream equipment (Ps. It means what kind of |

| inlet and outlet):__________m | equipment is used to discharge the material): _____ |

| ♦Material size:____mm | ♦Installation form is horizontal or inclined : ________; |

| ♦Material temperature: _______ ℃ | If it is inclined,what is the inclined degree_____° , |

| ♦Water content:____% | and whether a supporting frame is needed:_______ |

| ♦Material is corrosive or not: ____ (Ps. Yes or No) | ♦Working power supply: _____V ______HZ |