- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

577*1283*1698mm

-

Year:

-

2020

-

Power (kW):

-

2.6 kW

-

Weight (KG):

-

500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Model:

-

HZ-7014 Electronic Conveyor Belt Vulcanising Press Wholesaler

-

clamping force:

-

500N, 630N

-

Maximum fluid pressure(Mpa):

-

16,20

-

Hot plate specifications(mm):

-

400*400, 500*500

-

Dimension:

-

477*1163*1657mm, 577*1283*1698mm

-

Plunger diameter:

-

200mm

-

Motor Power:

-

2.6KW

-

Plunger stroke:

-

250mm

-

Weight:

-

500KG

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LIXIAN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

577*1283*1698mm

-

Year:

-

2020

-

Power (kW):

-

2.6 kW

-

Weight (KG):

-

500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Model:

-

HZ-7014 Electronic Conveyor Belt Vulcanising Press Wholesaler

-

clamping force:

-

500N, 630N

-

Maximum fluid pressure(Mpa):

-

16,20

-

Hot plate specifications(mm):

-

400*400, 500*500

-

Dimension:

-

477*1163*1657mm, 577*1283*1698mm

-

Plunger diameter:

-

200mm

-

Motor Power:

-

2.6KW

-

Plunger stroke:

-

250mm

-

Weight:

-

500KG

Product Description

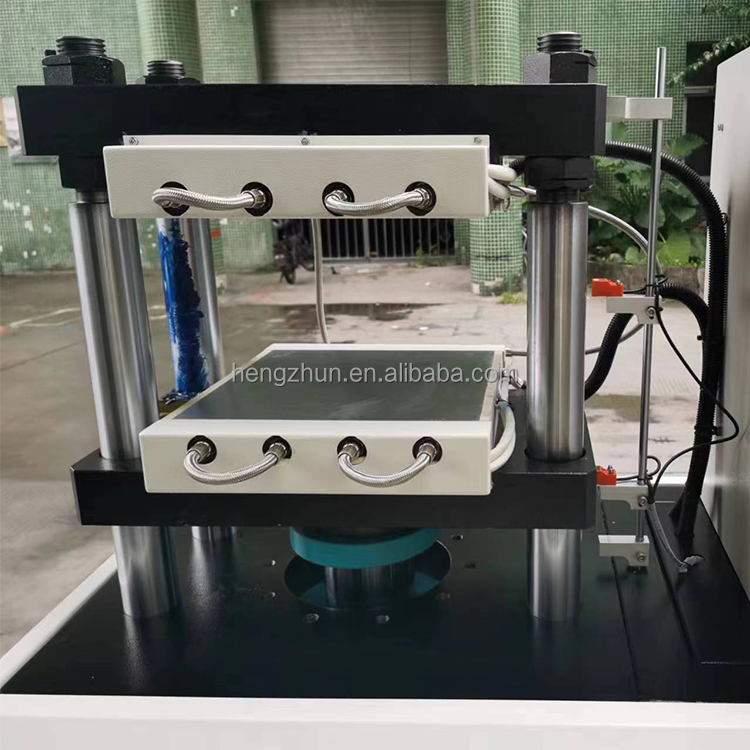

HZ-7014 Flat Vulcanizing Machine

Equipment Description:

This series of flat vulcanizing machine is the main equipment that can be used in pressing all kinds of rubber model product and non-model product. In addition, it also can be used in pressing all kinds of thermosetting plastic and foaming rubber and plastic product. With independent actuating unit and electric system, apply button centralized control. Within certain limits, working pressure and heating temperature can be adjusted. This kind of model, can be classified manual operate and semi-automatic operate. The flat vulcanizing machine with the function of a high degree of automation, easy operation,energy conservation and environment protection, and also superior performance

Introduction:

Flat vulcanizing machine is mainly used in vulcanizing flat belt(such as conveyor belt,driving belt). It is a kind of hydraulic machine. The main function of flat vulcanizing machine is providing the pressure and temperature for vulcanization. The pressure is generated from hydraulic system by hydraulic cylinder, and the temperature provided by heating tube. The control part of flat vulcanizing machine is mainly consist of high and low pump motor on hydraulic station,magnetic valve,vulcanization time,motion instructions and alarm function, etc

Specification

|

Model Number

|

HZ-7014

|

|

Capacity

|

10T, 20T, 30T, 50T, 80T,100T

|

|

Certification

|

ASTM /ISO/ROHS

|

|

Temperature range

|

Normal temperature~300℃

|

|

Temperature precision

|

±2℃

|

|

Heating up time

|

Normal temperature~160℃ about 20min

|

|

Heating plate size

|

350x350mm,500x500mm,1m*1m

|

|

The min.distance between up and lower heating plate

|

50mm

|

|

The max.distance between up and lower heating plate

|

300,500mm,800mm

|

|

Cylinder stroke

|

Max 250mm

|

|

Cylinder speed

|

11mm/s

|

|

Weight

|

2.5T

|

Application

It mainly used in producing vulcanizing parallel adhesive type, such as conveyor belt,driving belt, and pressing rubber products, foamed plastic,thermosetting plastic(bakelite) and other plastic products. It also suitable for O ring,the key products such as cell phone, keyboard,remote-control,sealing washer such as pressure cooker, electric cooker, mechanical accessories for household, food, health and medical treatment. At the same time,this machine alsocan be used in complex silicone and rubber fittings production and process, such as nipple,medical supplies, health product, artware, toy seal, electroconductive rubber, automotive rubber parts, industrial rubber parts,medical silicone product, sport equipment, all kinds of vessels, multilayer product and so on.

Main Features

1.Controlled by PC or manual, performance reliable, high degree of automation. Can automatically identify the wrong command,so avoid the accidence which caused by wrong operation. 2.The preprogrammed process can be locked, the operator can not change without authorization, so that guarantee the quality of pressed product. 3.With the function of timing open mold, automatically exhaust and reinforcing pressure,etc. 4.Optional: Manual operating or Automatic operating mode 5.Electrical heating pressing machine apply digital display(or pointed type) to control temperature, and control and display the heating plate temperature.

Details Images

Hot Searches