- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

AC 3*380V

-

Rated Duty Cycle:

-

100% 24 Hours

-

Use:

-

MIG/MAG/TIG Welding Machine

-

After-sales Service Provided:

-

Online support

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KELITE

-

Weight (KG):

-

2000

-

Voltage:

-

AC 3*380V

-

Rated Duty Cycle:

-

100% 24 Hours

-

Use:

-

MIG/MAG/TIG Welding Machine

-

After-sales Service Provided:

-

Online support

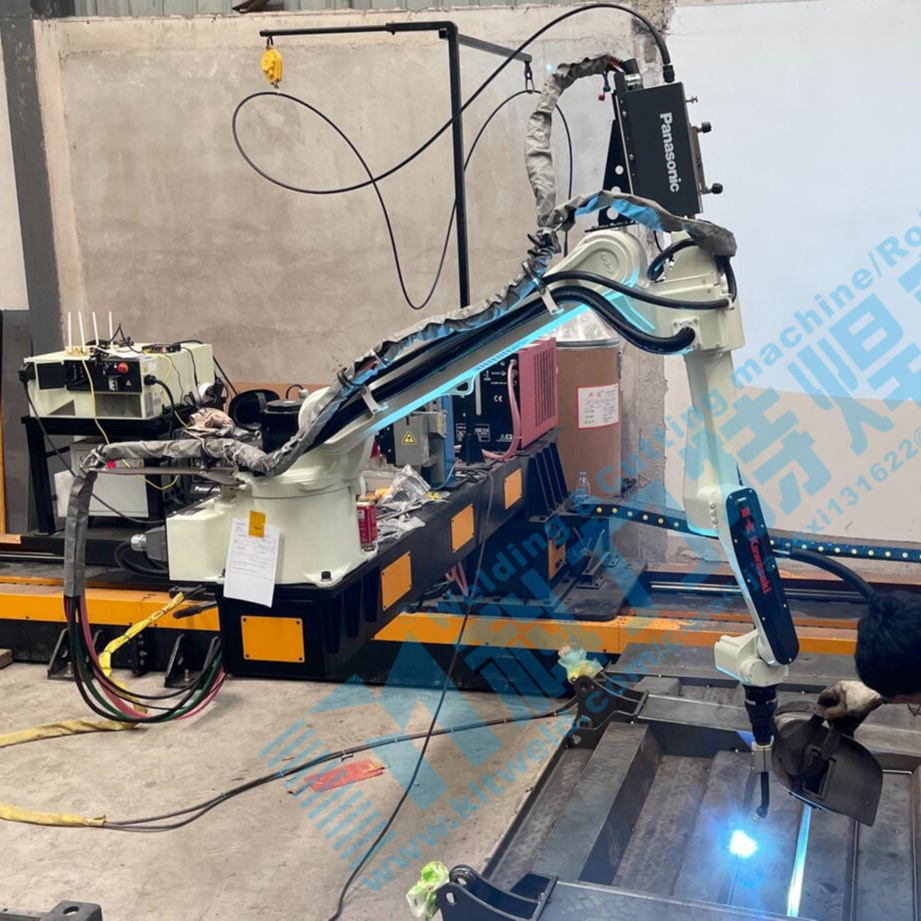

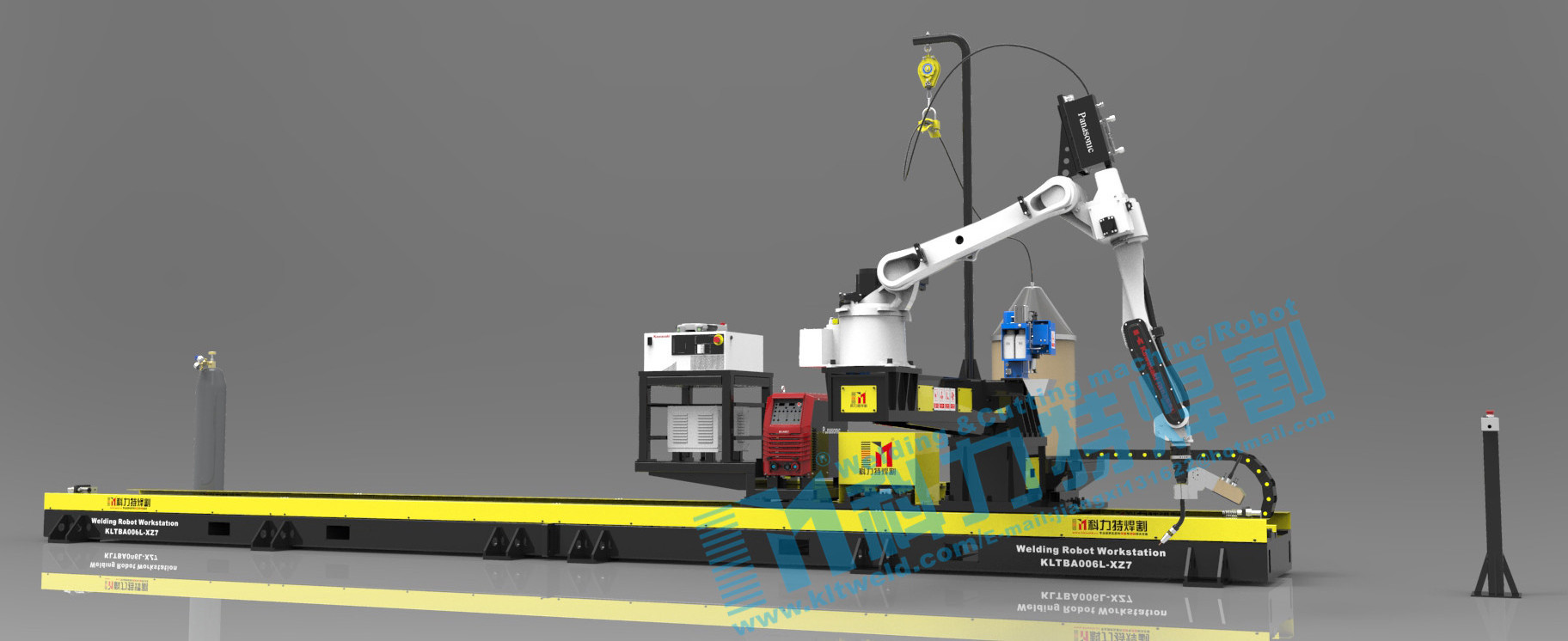

KLTBA006L-XZ7- Panasonic YD500GL5 ( configuration list)

|

|

Description |

Model |

Quantity |

|

1 |

6 Axis Welding Robot |

Model : BA006L R=2036mm , Load=6kg |

1set |

|

Teach pendant |

Color LCD with touch-panel; Emergency Stop SW, Teach Lock SW and Enable SW; Cable Line: Standard configuration(10m) |

||

|

Controller |

Model:E01; Input Power: AC200-AC220V±10% , 50/60Hz , 3 phases Controlled axes: Std. 7 axes (Max 9 axes); Memory capacity: 8MB; I/O signals: GPIO board (Input 32/Output 32); Dimensions: W550×D580×H278mm,40Kg |

||

|

Transformer |

AC 3*380V is converted to AC 3*220V |

||

|

2 |

External axis servo motor |

Add 7 Axis 2 KW (For walking track) |

1 set |

|

3 |

Robot extension cable |

Robot extension cable (5 m); And extension of external axis servo motor cable |

1 set |

|

4 |

Welding Power |

Model: Panasonic YD-500GL5 Load rate: 60% ;Pulse MIG/ Pulse MAG/CO2 Contain: Wire feeder , Control cable |

1set |

|

Wire Feeder |

Panasonic 6-axis robot dedicated wire feeder; Panasonic extension cable (5m) |

||

|

5 |

welding torch |

KLT-W500 ; special welding gun for Carbon steel, stainless steel welding; Water-cooled welding torch |

1set |

|

6 |

Cooling water tank |

Model:WL-20L |

1set |

|

7 |

Welding gun clearing station |

Clean up the torch, fuel injection, cut the wire ( 3 in 1 ) Chinese brand |

1set |

|

8 |

Wire feeding accessories |

Wire feeding tray bracket and wire feeding tube |

1set |

|

9 |

Peripheral buttons |

one external button box and communication cable 15m; Made by KELITEWELD |

1set |

|

10 |

Control cabinet bracket |

Made by KELITEWELD |

1set |

|

11 |

Barreled welding wire bracket |

Made by KELITEWELD |

1set |

|

12 |

Walking track |

Effective length 6000mm; Made by KELITEWELD |

1set |

|

13 |

Cantilever beam |

The total length is 2300mm; the structural parts are welded together |

1 set |

|

14 |

Wire feeder spring balancer |

Wire feeder support assembly, wire feeder 5m |

1 set |

|

15 |

Electrical cable |

Power cord, welding power ground cord, external conversion box, trachea, etc. |

1 set |

|

16 |

Conductive tip |

Φ=1.0mm/Φ=1.2mm, 1 row = 10 pieces |

10 rows |

|

17 |

Welding torch cover |

500A welding torch ; 1 row = 5 pieces |

10rows |

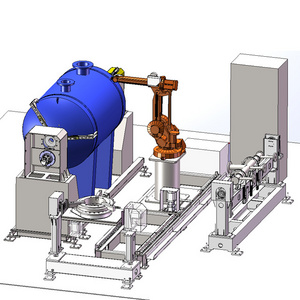

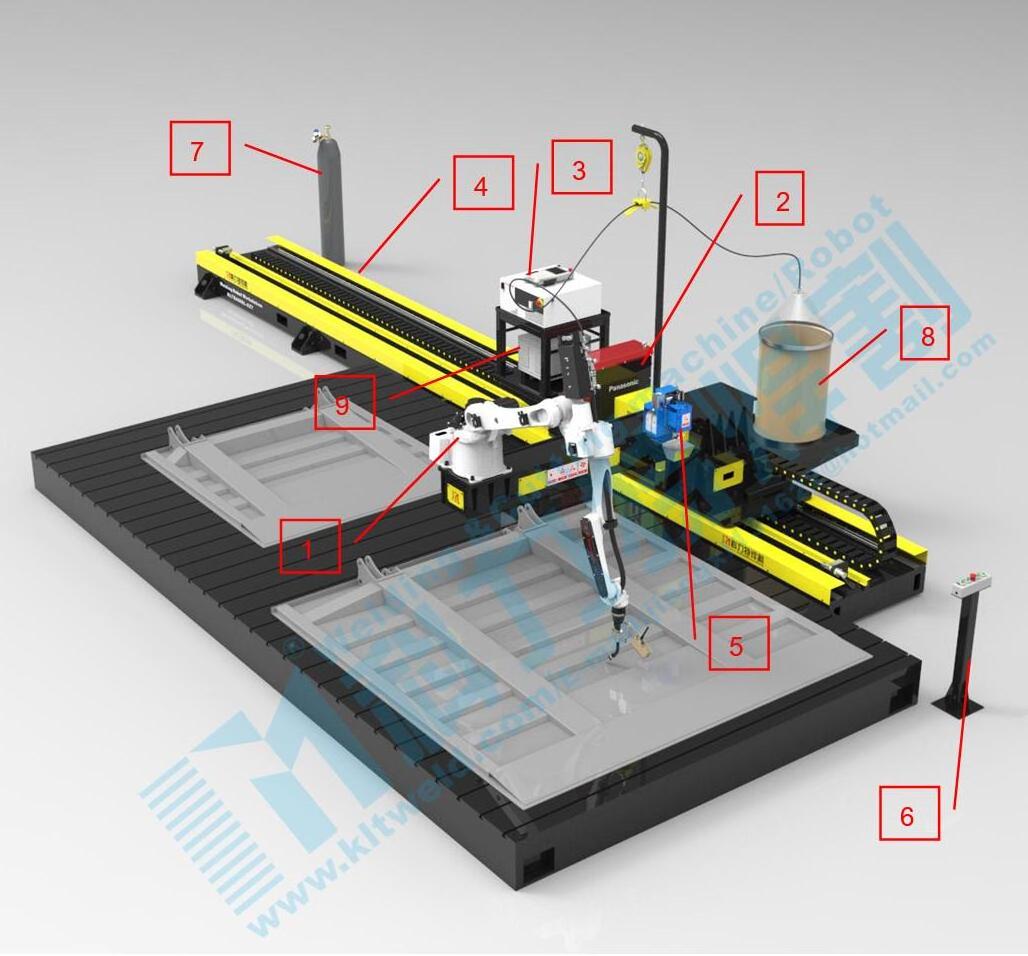

Numerical control welding robot workstation layout:

Picture for reference only

1 , 6 Axis Welding Robot ( BA006L ) ;2 , Welding power supply (Panasonic YD-500GL5);3 , Robot control cabinet and teach pendant(E01);4 , Robot servo walking track;5 , Welding gun cleaning station;6 , External start button box

7 , Carbon dioxide gas cylinder;8 , Barreled welding wire;9 , Transformer;

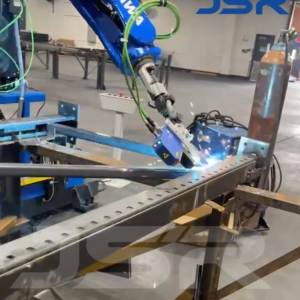

1 .1 Robot introduction

Kawasaki - BA006L( R=2036mm, Repeatability ±0.06 mm)

The BA series is a robotic series developed specifically for welding and is specifically designed for welding. It is simple to operate and can perform skilled welding operations with a simple teach-in operation. On the pendant is equipped with visual effects and easy to operate touch LCD color display. Robots and welders only need a cable connection, welding conditions can be classified storage, a key call .

|

Teaching methods |

Simple operation teaching AS language programming |

|

|

Action mode |

Manual mode |

Each axis independent, basic coordinate system, tool coordinate system |

|

Reproduction mode |

Each axis / straight line, circular interpolation action |

|

|

storage |

|

8MB (8000 steps equivalent) |

|

Universal signal |

External operation signal |

Emergency stop, external hold signal |

|

input Output |

32+32 |

|

6.5-inch color LCD screen, touch screen 640 × 480 pixels. Using backlight, the LCD screen easier to see.

Operating system using WINDOWS CE. The window display uses the drop-down menu, making the editing operation simple and easy.

1.2 Panasonic YD-350/500GL5 Welding power system