- Product Details

- {{item.text}}

Quick Details

-

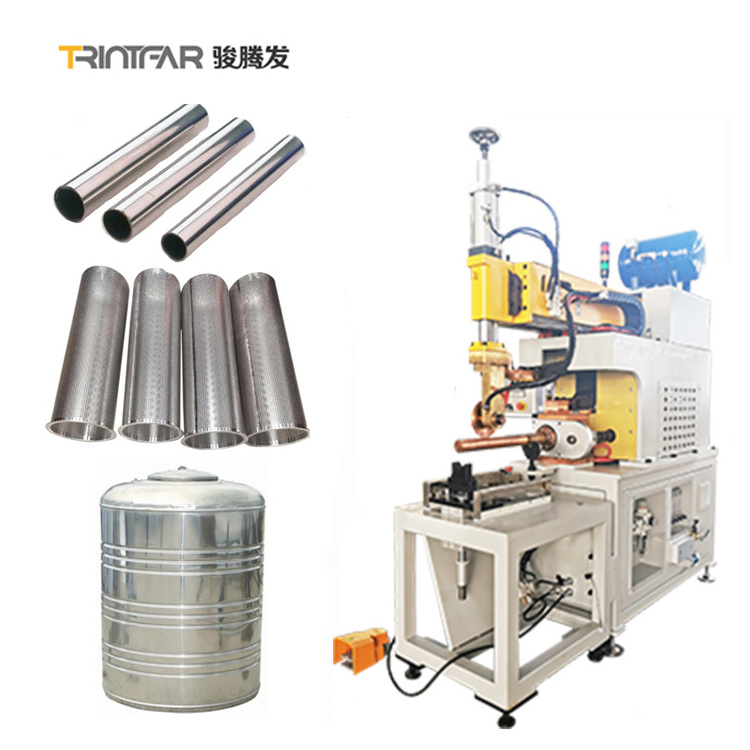

Welding Mode:

-

seam welding, seam welding

-

Welding Diameter:

-

80mm-100mm

-

Dimensions:

-

300-900mm

-

Use:

-

seam welding

-

Voltage:

-

380V

-

Weight (KG):

-

300 KG

-

Power (kW):

-

10kw

-

Power(W):

-

50KVA-200KVA

-

Welding speed:

-

0.6-2M/min

-

After sales Service Provided:

-

Free spare parts Field installation commissioning and training

-

After Warranty Service:

-

Video technical support

Quick Details

-

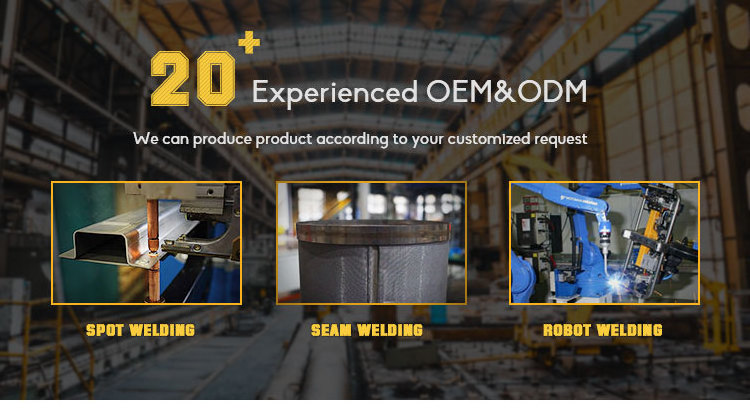

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

TRINTFAR

-

Forming Time:

-

0.1s-10s Adjustable

-

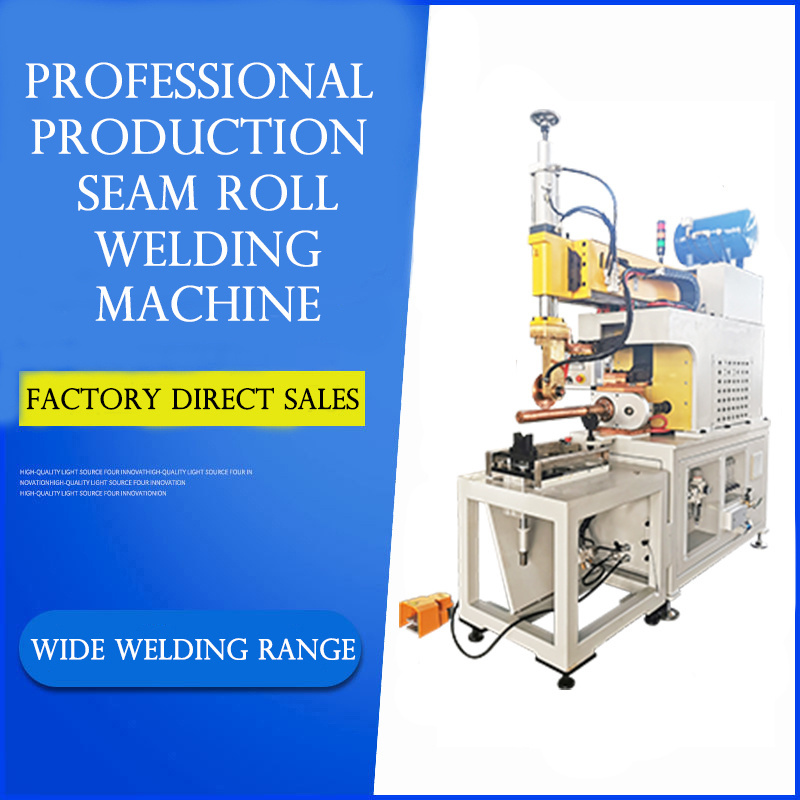

Welding Mode:

-

seam welding, seam welding

-

Welding Diameter:

-

80mm-100mm

-

Dimensions:

-

300-900mm

-

Use:

-

seam welding

-

Voltage:

-

380V

-

Weight (KG):

-

300 KG

-

Power (kW):

-

10kw

-

Power(W):

-

50KVA-200KVA

-

Welding speed:

-

0.6-2M/min

-

After sales Service Provided:

-

Free spare parts Field installation commissioning and training

-

After Warranty Service:

-

Video technical support

Product Description

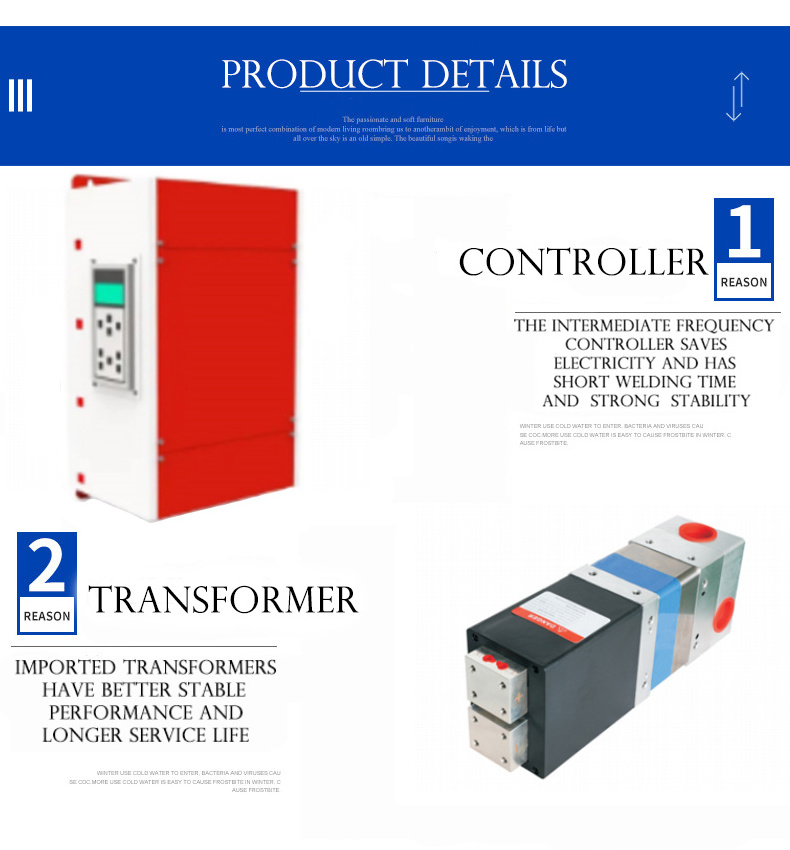

Feature

The power supply unit's duty are balanced. Three phase power make MD frequency inverter more adaptable in winding and pressure

of wire.

More preaser, faster current control, can analyse parameters more and faster compare with power frequency system.

Faster to set up current, the speed is 20folds quicker than traditional technic

Process more reliable: the majority of the application of solder DC welding metal effect will be even better.

Reduce operating costs, including energy savings each and every point of welding as well as shortening the welding cycle.

Save energy :especially suitable for welding thick workpieces and high-conductivity metal .such as aluminum and galvanized

steel sheet.etc.

of wire.

More preaser, faster current control, can analyse parameters more and faster compare with power frequency system.

Faster to set up current, the speed is 20folds quicker than traditional technic

Process more reliable: the majority of the application of solder DC welding metal effect will be even better.

Reduce operating costs, including energy savings each and every point of welding as well as shortening the welding cycle.

Save energy :especially suitable for welding thick workpieces and high-conductivity metal .such as aluminum and galvanized

steel sheet.etc.

Specification

|

Item

Model

|

Maximum Short Current

KA

|

Rated Duty Cycle

%

|

Secondary Voilage

V

|

Rated Power

KVA

|

Electrode

Pressure

N

|

Electrode

Stroke

mm

|

Cooling Water

L\mim

|

|

FM-20

|

20

|

50

|

≈9.8

|

≤50

|

4700

|

80

|

24

|

|

FM-25

|

25

|

50

|

≈9.8

|

≤70

|

4700

|

80

|

24

|

|

FM-40

|

40

|

50

|

≈11.6

|

≤120

|

7300

|

80

|

30

|

|

FM-60

|

60

|

50

|

≈11.6

|

≤160

|

12000/18000

|

100

|

50

|

|

FM-80

|

80

|

50

|

≈11.6

|

≤240

|

12000/18000

|

100

|

50

|

|

FM-120

|

120

|

50

|

≈11.6

|

≤300

|

18000

|

100

|

60

|

Hot Searches