- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

670kg

-

Size:

-

2500*1400*1700 mm

-

Power:

-

4.03kw

-

Productivity:

-

25-40L/Hour

-

Weight (KG):

-

420 kg

-

Product name:

-

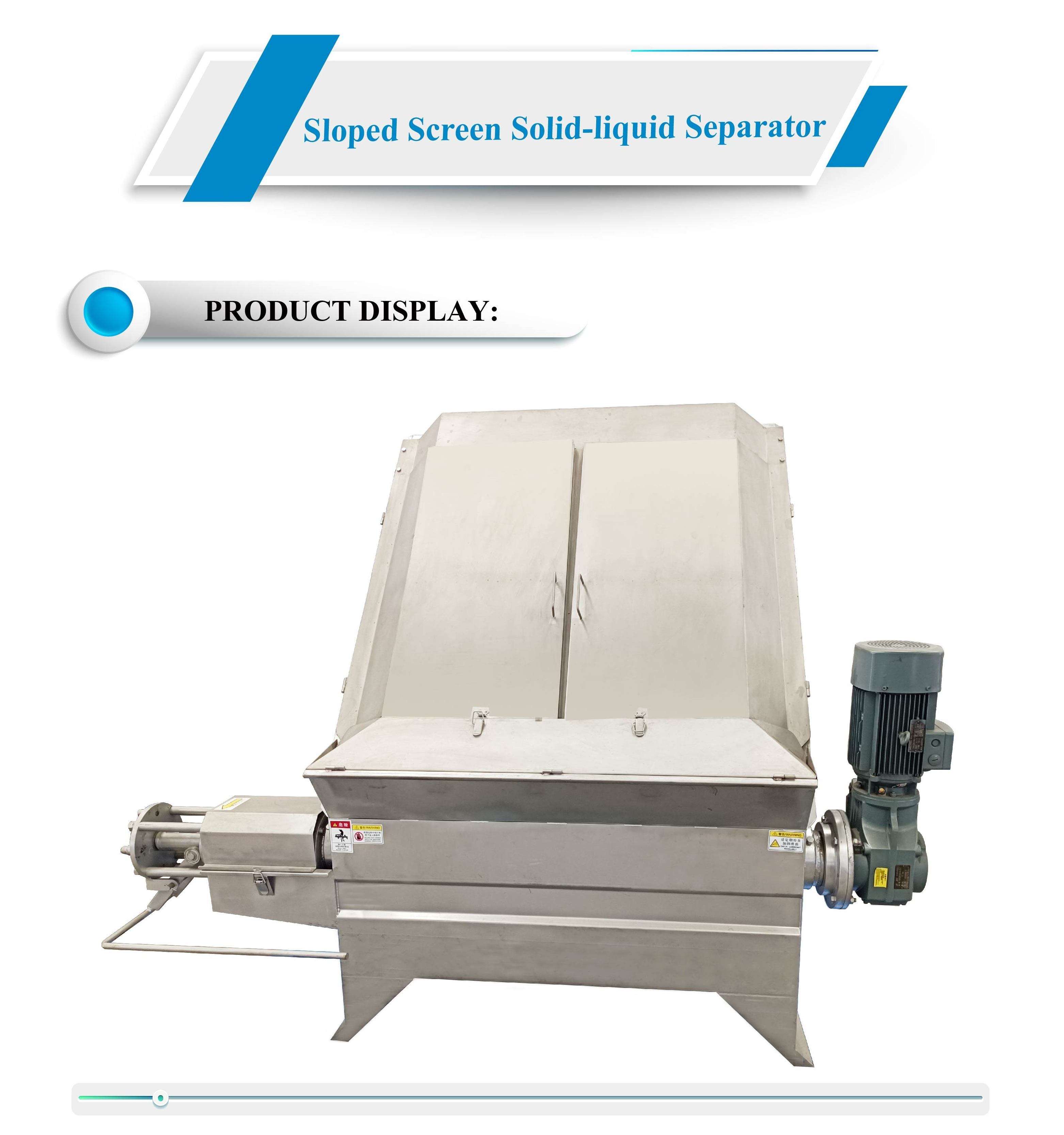

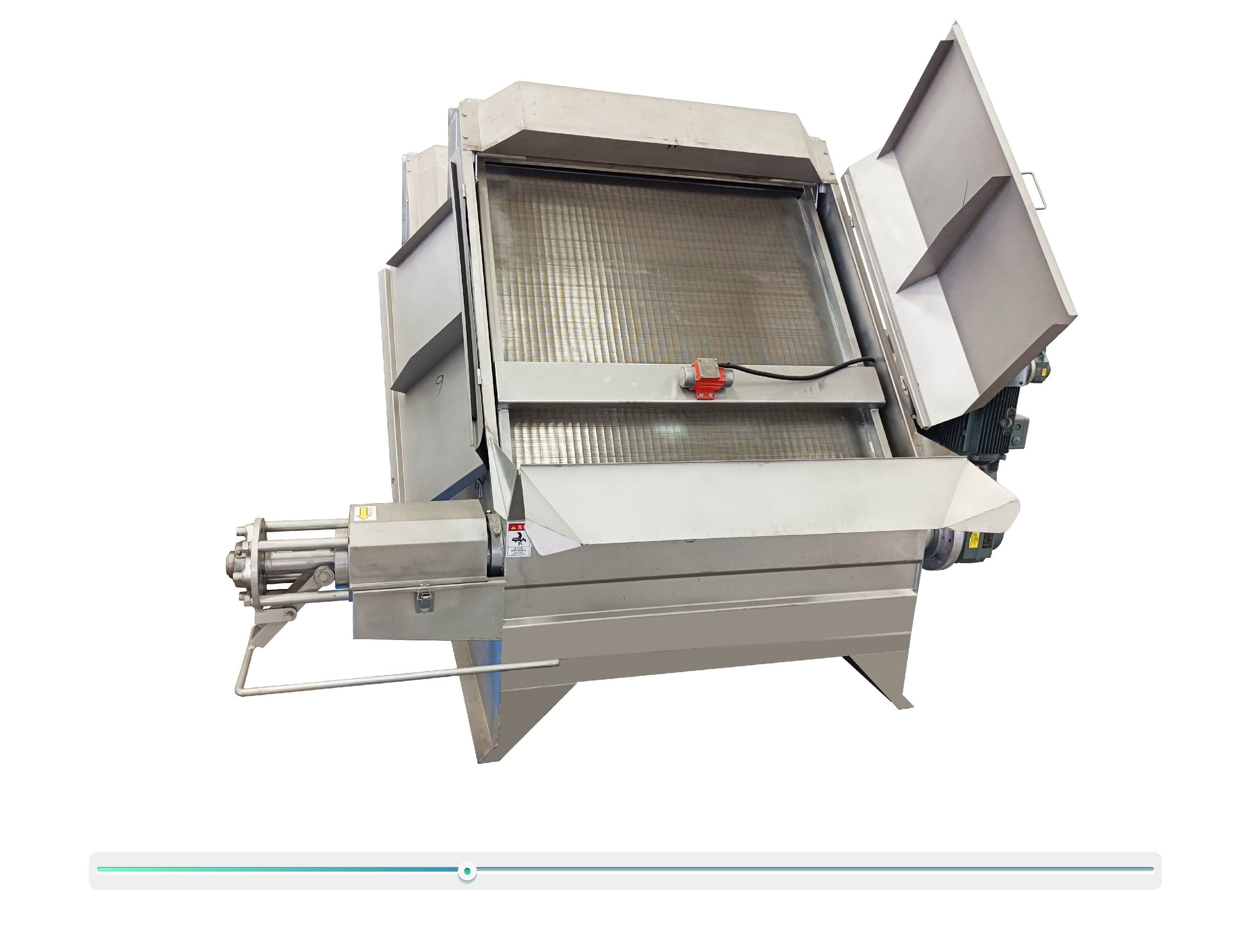

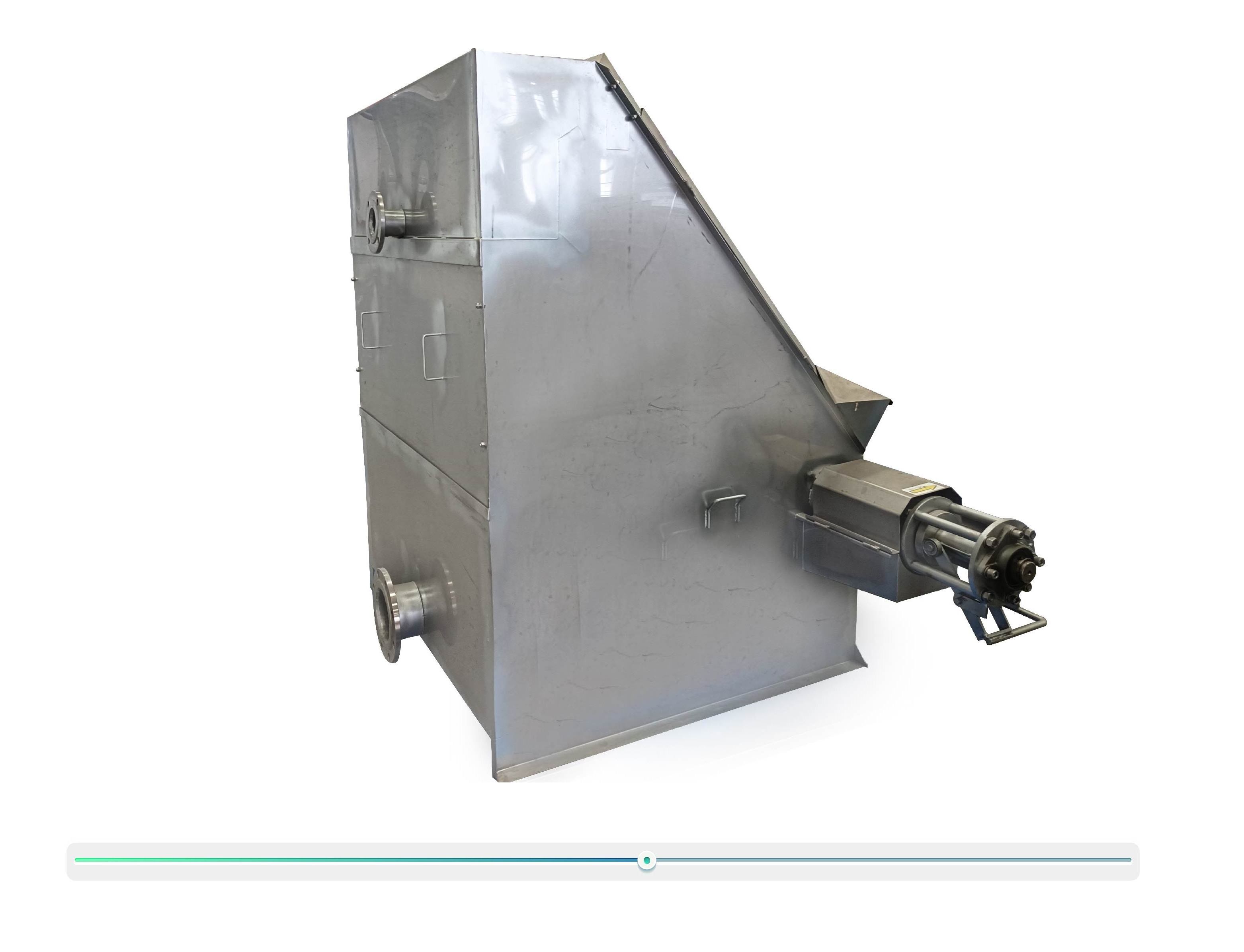

Sloped screen solid-liquid separator

-

Brand:

-

IEPP

-

Application:

-

Solid-liquid Separation

-

Control:

-

Button/PLC

-

Raw material:

-

SS 304

-

Package:

-

Plywood Package

-

Voltage:

-

380V

-

Type:

-

Screw

-

Function:

-

Solid Liquid Separator

-

MOQ:

-

1 Set

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

IEPP

-

Material:

-

standard wood package

-

Weight:

-

670kg

-

Size:

-

2500*1400*1700 mm

-

Power:

-

4.03kw

-

Productivity:

-

25-40L/Hour

-

Weight (KG):

-

420 kg

-

Product name:

-

Sloped screen solid-liquid separator

-

Brand:

-

IEPP

-

Application:

-

Solid-liquid Separation

-

Control:

-

Button/PLC

-

Raw material:

-

SS 304

-

Package:

-

Plywood Package

-

Voltage:

-

380V

-

Type:

-

Screw

-

Function:

-

Solid Liquid Separator

-

MOQ:

-

1 Set

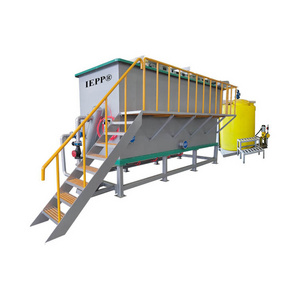

IEPP factory supply municipal textile dairy process fiber solid liquid sewage industrial machine wastewater treatment equipment

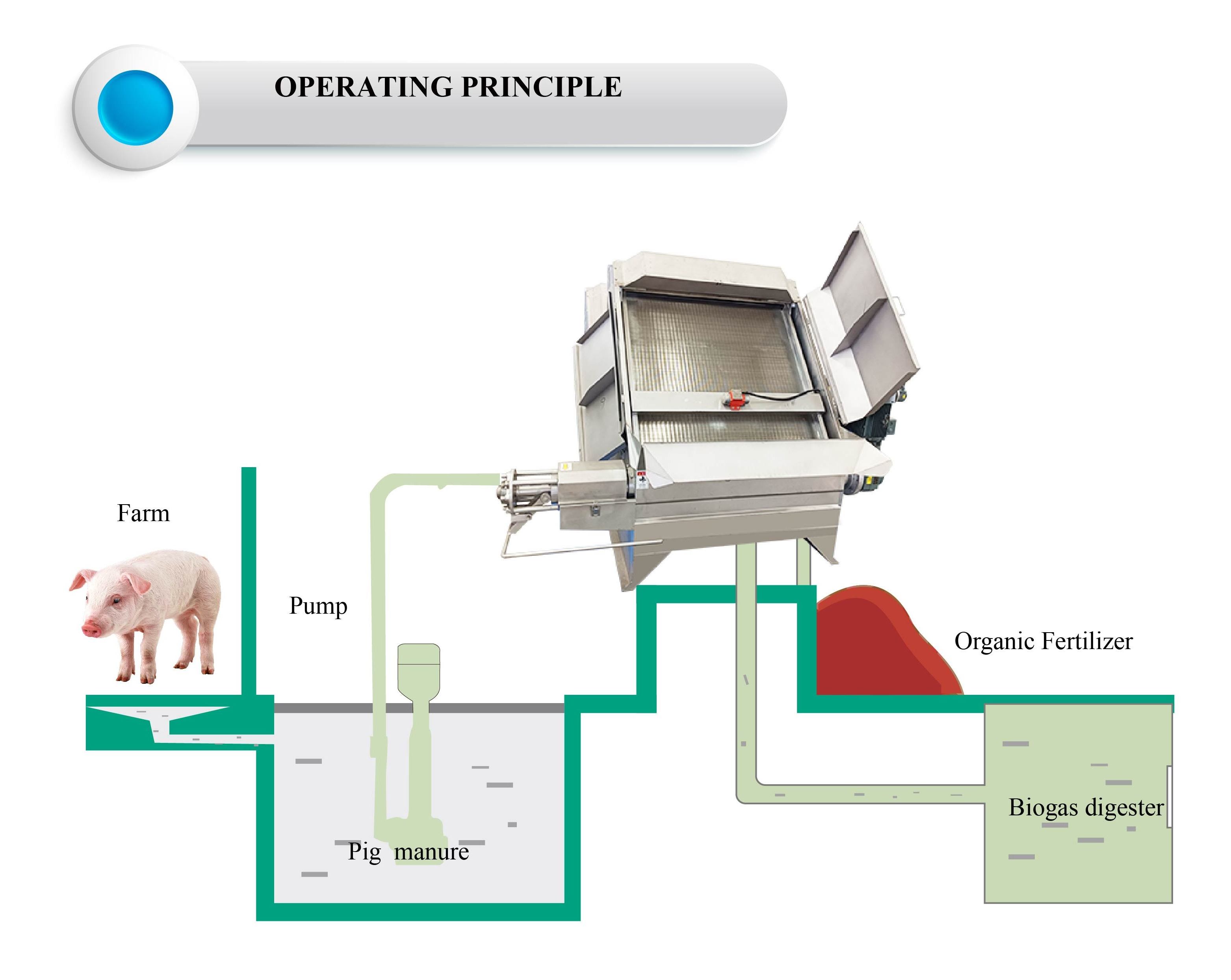

IEPP® Slope screen solid-liquid separator is used to separate coarse solids from diluted raw pig manure.

The equipment is generally performed as a pre-treatment for subsequent manure treatment processes, reduce organic matter loading to storages/lagoons, reduce GHG emissions from long-term storages, facilitate pumping to distant fields/storages, and/or use of separated solids for stall bedding/compost media.

Primary Benefits

Removal of organic matter in theory can contribute to manure storage odor reduction overall but in practice daily odor emission can be more noticeable.

Reduce organic matter loading to storages/lagoons.

Reduce GHG emissions from long-term storages.

Use of separated solids for stall bedding/compost media.

Secondary Benefits

Pre-treatment for subsequent manure treatment processes

Nutrient separation – about 20% of the mass of the original manure nutrient mass is contained in the separated solids.

Solid-liquid separation provides the opportunity for farms to more easily pump manure long distances thus reducing manure hauling with tanker trucks.

Step 1: The sewage is sucked up from the cesspool by the sewage pump. Through the slant 45 V-shaped wire screen, most of the water is filtered by gravity.

Step 2: The material flows to the spiral blade through the vibration motor and then is transmitted to the rotary drum screen filter by the spiral blade.

Step 3: In the drum screen, a part of the sewage flows out through the extrusion, and the extruded material comes out from the discharge port.

|

YP-GY700

|

1.50

|

0.80

|

1.70

|

SS304

|

7-15

|

|

YP-GY900

|

2.20

|

1.00

|

1.90

|

SS304

|

10-20

|

|

YP-GY1200

|

2.20

|

1.50

|

2.20

|

SS304

|

18-30

|

|

YP-GY1500

|

4.00

|

1.60

|

2.30

|

SS304

|

25-40

|

1.Q: Are you a factory or trading company?

A: We are a factory. we have rich experience for

manufacturing sewage treatment equipment for

more than 15 years.

2.Q: Do you have minimum order quantity reguest?

A: No minimum order, but it can get a discount if

you order a large quantity.

3.Q: Can you meet my special requirements for my products?

A: Yes, we have a professional design team.

We can provide drawings according to your requirements.

4. Q: How to buy your products?

A: You can provide us your water sources, water quality,

flow rate and ground area (contact us for more details)

5. Q: How to pay?

A: TT and L/C are acceptable and TT will be more

appreciated. 50% deposit before producing,

50% balance before loading.

6. Q: What is the delivery time?

A: It depends on order quantities. Generally speaking the

delivery time will be within 4 to 6 weeks.

Hot Searches