- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by theoretical weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JUHE

-

Outer Diameter:

-

30 - 200 mm

-

Thickness:

-

0.3mm-4.0mm

-

Grade:

-

carbon steel

-

Product name:

-

Carbon Steel Pipe

-

Type:

-

Welded ERW

-

Material:

-

Q195/Q235/Q345/S235JR/S275JR/S355JR

-

Shape:

-

Round Pipe Tube

-

MOQ:

-

25 Tons

-

Keyword:

-

High quality carbon steel

-

Packing:

-

Standard Seaworthy Packing

-

Technology:

-

Hot Rlloed

-

Color:

-

High quality carbon steel

Quick Details

-

Section Shape:

-

Round

-

Surface Treatment:

-

Hot Rolled

-

Tolerance:

-

±1%

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

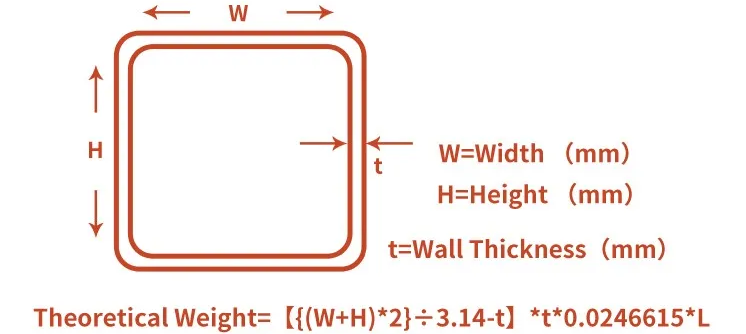

by theoretical weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JUHE

-

Outer Diameter:

-

30 - 200 mm

-

Thickness:

-

0.3mm-4.0mm

-

Grade:

-

carbon steel

-

Product name:

-

Carbon Steel Pipe

-

Type:

-

Welded ERW

-

Material:

-

Q195/Q235/Q345/S235JR/S275JR/S355JR

-

Shape:

-

Round Pipe Tube

-

MOQ:

-

25 Tons

-

Keyword:

-

High quality carbon steel

-

Packing:

-

Standard Seaworthy Packing

-

Technology:

-

Hot Rlloed

-

Color:

-

High quality carbon steel

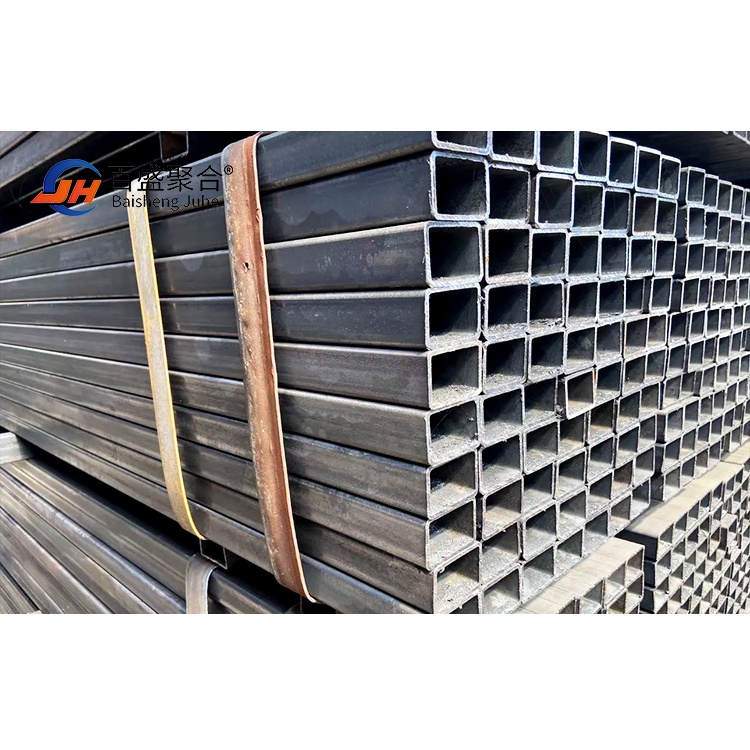

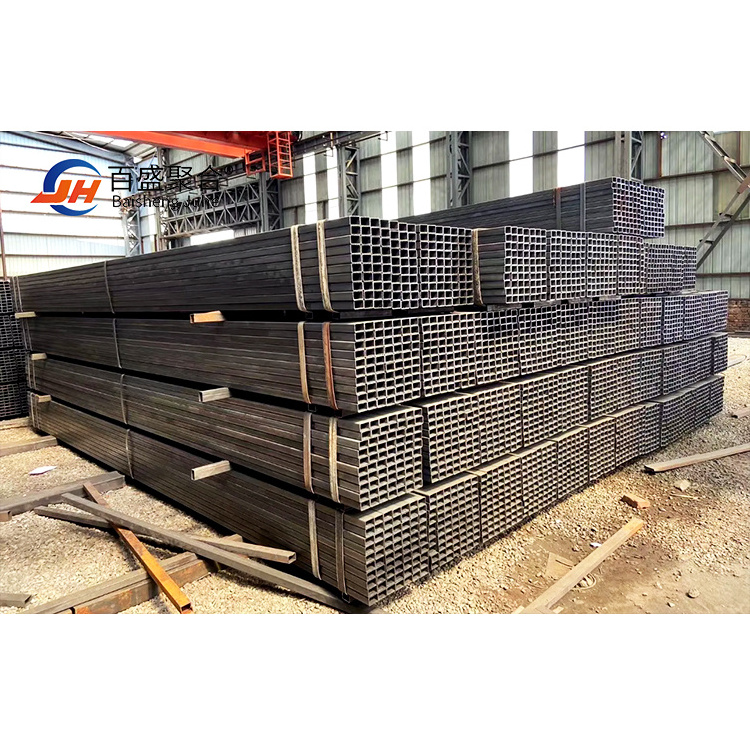

Hot Rolled Hollow Section Mild Carbon Ms Iron Tubes Cheap Price Erw seamless square tube Steel Pipes

Products Description

With an annual output of 15 million tons, Juhe steel is the largest ERW square pipe, rectangular pipe, hollow pipe, galvanized pipe and spiral welded pipe manufacturer in China. Annual sales reached $5 billion. Juhe steel has 59 black ERW pipe production lines, 10 galvanized pipe production lines ,3 spiral welded pipe production lines,1 JCOE LSAW steel pipe production line. Square pipe 10 * 10 * 0.5mm to 1000 * 1000 * 60MM, rectangular steel pipe 10 * 15 * 0.5mm to 800 * 1100 * 60MM, spiral pipe Ø 219-1420mm can be made of yield strength from Q (s) 195 MPa to Q (s) 690 MPa.Juhe steel can produce square rectangular tubes according to ASTM A500/A501,JIS G3466,EN10219,EN10210,BV,DIN2240 and AS1163,GB/T9711,GB/T3091,GB/T3094,GB/T6728 etc,

and our mill were certified by BC1,EPD,PHD,ISO9001,ISO14001,ISO45001.

Juhe steel has the largest steel pipe inventory in China, which can meet the urgent purchasing demand of customers. Welcome everyone to contact Yuantai Derun,And visit our factory online or offline.

|

COMMODITY NAME

|

SQUARE AND RECTANGULAR HOLLOW SECTION PIPE/ TUBE

|

|

MATERIAL GRADE

|

Q195 = S195 / A53 Grade A

Q235 = S235 / A53 Grade B / A500 Grade A / STK400 / SS400 / ST42.2 Q355 = S355JR / A500 Grade B Grade C |

|

STANDARD

|

ASTM A500 Gr.A / B/ C

|

|

PIPE SURFACE

|

Galvanized, black painted, or anti-rust oiled

|

|

PIPE ENDS

|

PLAIN ENDS

|

|

CERTIFICATES

|

ISO 9001 / BSI/ UL / FM

|

|

TRADE TERMS

|

FOB/ CFR/ CIF/ EXW/ FCA

|

|

PAYMENT TERMS

|

30%&70% T/T ; 100% LC AT SIGHT (others can be negotiated)

|

|

DELIVERY TIME

|

30-45 DAYS AFTER RECEIVE DEPOSIT OR LC

|

|

BRAND

|

Juhe steel (HOT SALES)

|

|

HOT SALES MARKET

|

Southeast Asia, South Asia, Middle East, Europe, Middle&South America, Africa and Oceania

|

|

REGULAR SIZE

|

|

|

||

|

SIZE (OUTER DIAMETER)

|

WALL THICKNESS

|

LENGTH

|

||

|

20x20 / 25x25

|

1.2MM --2.75MM

|

6M IN STOCK (OR CUSTOMIZED)

|

||

|

30x30 / 20x40 / 30x40 / 25x40

|

1.2MM -- 3.5MM

|

6M IN STOCK (OR CUSTOMIZED)

|

||

|

40x40 / 50x5030x50 / 25x50 / 30x60 / 40x60

|

1.2MM -- 4.75 MM

|

6M IN STOCK (OR CUSTOMIZED)

|

||

|

60x60 / 50x70 / 40x80 / 40x50

|

1.2 MM -- 5.75 MM

|

6M IN STOCK (OR CUSTOMIZED)

|

||

|

70x70 / 60x80 / 50x80 / 100x40 / 50x90

|

1.5MM -- 5.75 MM

|

6M IN STOCK (OR CUSTOMIZED)

|

||

|

75x75 / 80x80 / 90x90

60x100 / 50x100 / 120x60 / 100x80 / 60x90 |

1.5MM -- 7.75 MM

|

6M IN STOCK (OR CUSTOMIZED)

|

||

|

100x100 / 120x80

|

1.8MM -- 7.75 MM

|

6M IN STOCK (OR CUSTOMIZED)

|

||

|

120x120 / 130x130

180x80 / 160x80 / 100x150 / 140x80 / 140x60 |

2.5MM -- 10.0 MM

|

6M IN STOCK (OR CUSTOMIZED)

|

||

|

140x140 / 150x150 / 100x180 / 200x100

|

2.5MM -- 10.0 MM

|

6M IN STOCK (OR CUSTOMIZED)

|

||

|

160x160 / 180x180 / 200x150

|

3.5MM -- 11.0 MM

|

6M IN STOCK (OR CUSTOMIZED)

|

||

|

200x200 / 250x150 / 100x250

|

3.5MM -- 11.0 MM

|

6M IN STOCK (OR CUSTOMIZED)

|

||

|

250x250 / 250x200 / 300x150 / 300x200

|

4.5MM -- 15.0 MM

|

6M IN STOCK (OR CUSTOMIZED)

|

||

|

300x300 / 350x200 / 350x250 /300x150

|

4.5MM -- 15.0 MM

|

6M IN STOCK (OR CUSTOMIZED)

|

||

|

350x350

350x300 / 450x250 / 400x300 / 500x200 |

4.5MM -- 15.75 MM

|

6M IN STOCK (OR CUSTOMIZED)

|

||

|

400x400 / 280x280

450x300 / 450x200 / 400x350 / 400x250 / 500x250 / 500x300 |

4.5MM -- 15.75 MM

|

6M IN STOCK (OR CUSTOMIZED)

|

||

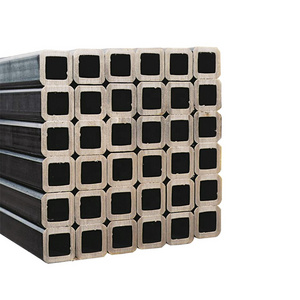

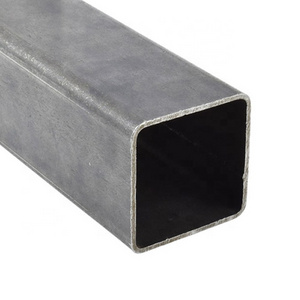

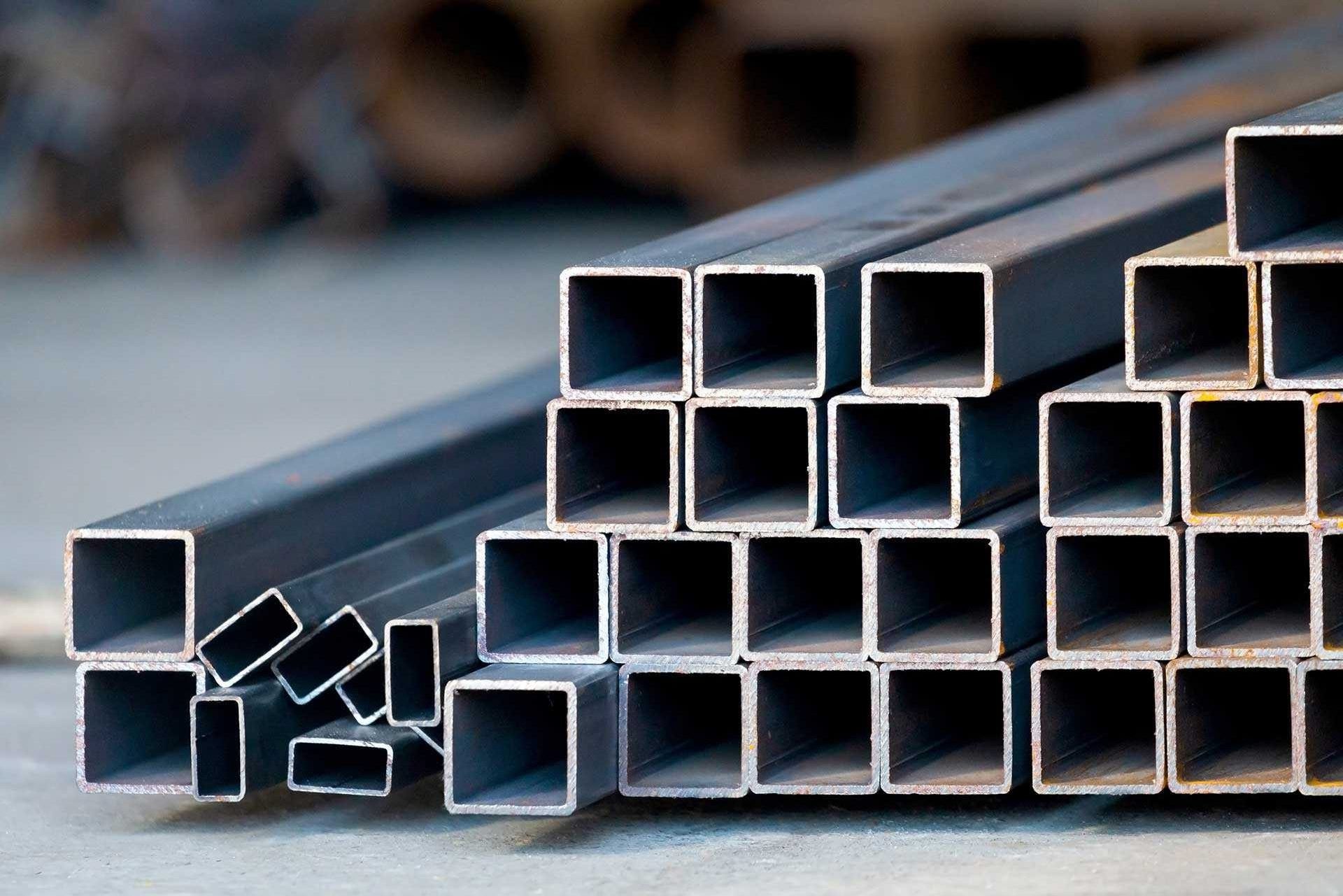

Structural Hollow Sections (SHS) are very effective in resisting buckling loads, resulting in a high strength-to-mass ration. High flexural stiffness in all directions is combined with high torsional stiffness.

When used as beams, the need for lateral support is reduced. Columns and beams do not need to be checked for torsional-flexural buckling if they fall within the limits of the slenderness ratio or when the height-to-breadth ratio of these sections does not exceed 2 to 1.

The result is less material usage and a competitive engineering solution. The lighter, yet stiffer structural members simplify the erection as longer spans can be pre-fabricated. Connecting members are typically joined by welding under strict factory conditions.

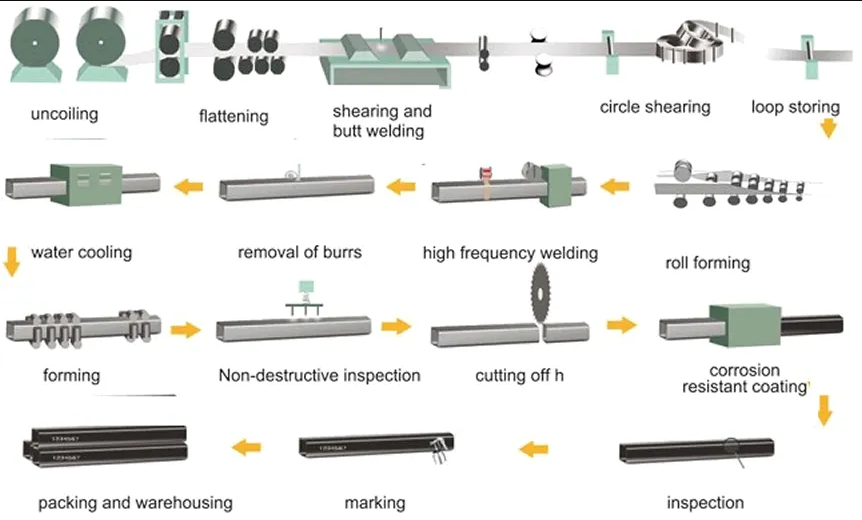

THE PRODUCTION PROCESS

Product Advantage

Chemical Properties %

|

|

|

Grade

|

P-5

|

P-9

|

P-11

|

P-22

|

P-91

|

|

|

Element

|

|

UNS Designation

|

K41545

|

S50400

|

K11597

|

K21590

|

K91560

|

|

|

Carbon

|

|

0.15 max

|

0.15 max

|

0.05 – 0.15

|

0.05 – 0.15

|

0.08 – 0.12

|

V at 0.18 – 0.25

|

|

|

Manganese

|

|

0.30 – 0.60

|

0.30 – 0.60

|

0.30 – 0.60

|

0.30 – 0.60

|

0.30 – 0.60

|

N at 0.030 – 0.070

|

|

|

Phosphorous, max

|

|

0.025

|

0.025

|

0.025

|

0.025

|

0.020

|

Ni at 0.40 max

|

|

|

Sulfur, max

|

|

0.025

|

0.025

|

0.025

|

0.025

|

0.010

|

Al at 0.02 max

|

|

|

Silicon

|

|

0.50 max

|

0.25 – 1.00

|

0.50 – 1.00

|

0.50 max

|

0.20 -0.50

|

Cb at 0.06 – 0.10

|

|

|

Chromium

|

|

4.00 – 6.00

|

8.00 – 10.00

|

1.00 – 1.50

|

1.90 – 2.60

|

8.00 – 9.50

|

Ti at 0.01 max

|

|

|

Molybdenum

|

|

0.45 -0.65

|

0.90 – 1.10

|

0.44 – 0.65

|

0.87 – 1.13

|

0.85 – 1.05

|

Zr at 0.01 max

|

|

Description of application effect

Alloy steel is steel that is alloyed with a variety of elements in total amounts between 1.0% and 50% by weight to improve its mechanical properties. Alloy steels are broken down into two groups: low-alloy steels and high-alloy steels. The difference between the two is somewhat arbitrary: Smith and Hashemi define the difference at 4.0%, while Degarmo, et al., define it at 8.0%.Most commonly, the phrase "alloy steel" refers to low-alloy steels.

Strictly speaking, every steel is an alloy, but not all steels are called "alloy steels". The simplest steels are iron (Fe) alloyed with carbon (C) (about 0.1% to 1%, depending on type). However, the term "alloy steel" is the standard term referring to steels with other alloying elements added deliberately in addition to the carbon. Common alloyants include manganese (the most common one), nickel, chromium, molybdenum, vanadium, silicon, and boron. Less common alloyants include aluminum, cobalt, copper, cerium, niobium, titanium, tungsten, tin, zinc, lead and zirconium.

This specification2 covers nominal wall and minimum wall seamless ferritic alloy-steel pipe intended for high temperature service. Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Selection will depend upon design, service conditions, Mechanical Properties, and high-temperature characteristics.

ASTM A335 Pipe (ASME S/A335, Chorme-Moly) is a seamless ferritic Alloy-Steel Pipe for high temperature service. Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Sometimes referred to as “P Grade”, Chrome Moly Pipe is popular in P-Grades P5, P9, P11, P22, and P91. The most common use of grades P11, P22, and P91 is in the power industry and petro-chemical plants, Grades P5 and P9 are commonly used in refineries.

A335 is often called chrome moly pipe because of the chemical makeup of Molybdenum (Mo) and Chromium (Cr). Molybdenum increases the strength of steel as well as the elastic limit, resistance to wear, impact qualities, and hardenability. Moly increases the resistance to softening, restrains grain growth and makes chromium steel less susceptible to embrittlement. Moly is the most effective single additive that increases high temperature creep strength. It also enhances the corrosion resistance of steel, and inhibits pitting. Chromium (or chrome) is the essential constituent of stainless steel. Any steel with 12% or more Chrome is considered stainless. Chrome is virtually irreplaceable in resisting oxidation at elevated temperatures. Chrome raises the tensile, yield, and hardness at room temperatures. The composition chrome moly alloy steel pipe make it ideal for use in power plants, refineries, petro chemical plants, and oil field services where fluids and gases are transported at extremely high temperatures and pressures.

Stocks a full range of the following A335 pipe grades:

ASTM A213 seamless pipes tubes

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

This specification covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes. Grades containing the letter H in their designation have requirements different from those of similar grades not containing the letter H. These different requirements provide higher creep-rupture strength than normally achievable in similar grades without these different requirements. The tubes shall be made by the seamless process and shall be either hot finished or cold finished, as specified. Grade TP347HFG shall be cold finished. Heat treatment shall be done separately and in addition to heating for hot forming. The ferritic alloy and ferritic stainless steels shall be reheated. On the other hand, austenitic stainless steel tubes shall be furnished in the heat-treated condition. Alternatively, immediately after hot forming, while the temperature of the tubes is not less than the minimum solution temperature, tubes may be individually quenched in water or rapidly cooled by other means. Tension test, hardness test, flattening test, and flaring test shall be done to each tube. Also, each tube shall be subjected to the nondestructive electric test or hydrostatic test.

Hot Searches