- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

240*115*90 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Voltage:

-

220V/ 380V/400V/415V/480V

-

Dimension(L*W*H):

-

6930-2030-2750

-

Marketing Type:

-

discount

-

Weight (KG):

-

26800 kg

-

Keywords:

-

Brick Making Mahcine

-

Product Name:

-

Automatic brick Making Machine

-

Raw material:

-

Cement/ Concrete

-

Block Type:

-

Hollow Block/ standard block

-

Machine Type:

-

Hydralic Pressure

-

Local Service Location:

-

Russia

-

After-sales Service Provided:

-

Video technical support

-

Certification:

-

ISO9001

Quick Details

-

Type:

-

Hollow Block Making Machine

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

12000 pcs/8hours

-

Brick size:

-

240*115*90 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Voltage:

-

220V/ 380V/400V/415V/480V

-

Dimension(L*W*H):

-

6930-2030-2750

-

Marketing Type:

-

discount

-

Weight (KG):

-

26800 kg

-

Keywords:

-

Brick Making Mahcine

-

Product Name:

-

Automatic brick Making Machine

-

Raw material:

-

Cement/ Concrete

-

Block Type:

-

Hollow Block/ standard block

-

Machine Type:

-

Hydralic Pressure

-

Local Service Location:

-

Russia

-

After-sales Service Provided:

-

Video technical support

-

Certification:

-

ISO9001

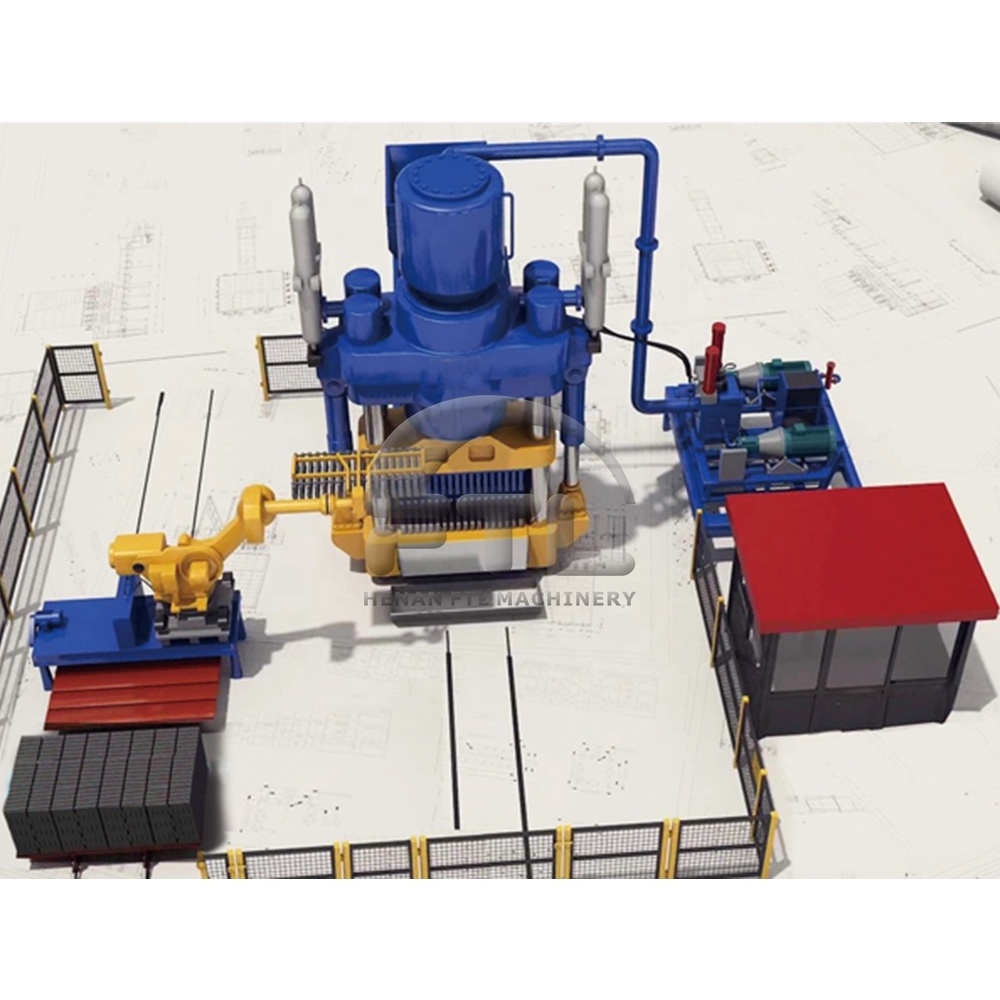

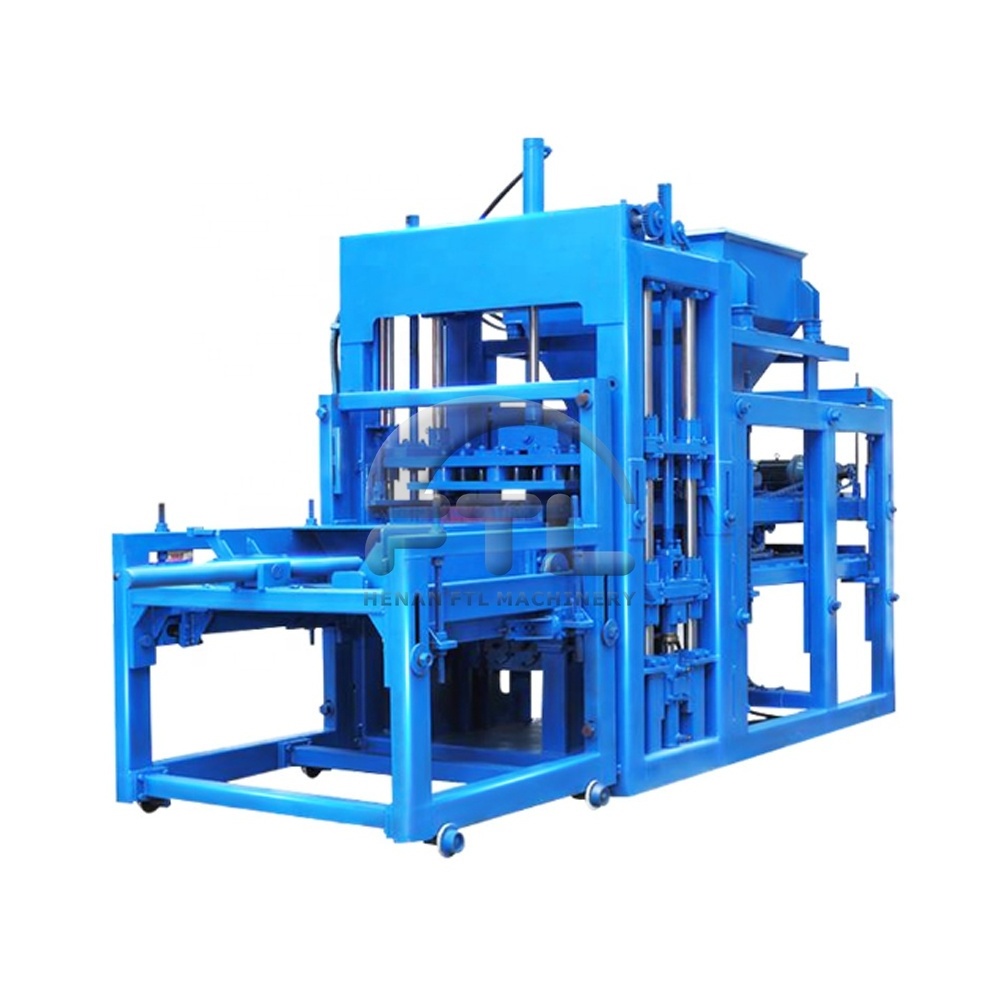

FTL Automatic Hydraulic Brick Making Machine

FTL Automatic Hydraulic Brick Making Machine

The production capacity depends on this forming machine and it is also the essential part of the whole production line. You can change moulds on this parts to make different shapes of blocks, bricks, colored-paving stones and curbs.

• The process is controlled by PLC and fitted with remote control device. For PLC control system, we usually use Japan Mitsubishi or Taiwan Brand.

• The electricity motor for host machine we use Germany Siemens motor, for other parts ,we use CE motor.

• about the switches, we will use France Schneider or China CHNT.

• Rakes in several rows make sure raw materials fed well-distributed.

• Hydraulic components we use Taiwan JiuGang famous brands.

• The demoulding synchronizer avoids the damage to concrete products.

• The vibration system contains two parts, one is up-mould vibration box, it is electricity motor to supply the power for up-mould vibration box. And the down mould, there have one big vibration. When the scatter material work finish, the hydraulic power with the two vibration power will assure the good quality for product.

• The mould is processed with carburizing, nitriding, wolfram carbide and quenching which ensures its strength reach to 54~58 HRC and can be used 100 thousand times.

|

Main Technical Specifications

|

|||

|

Overall Dimension

|

8300x1860x3000mm

|

||

|

Rated pressure

|

21Mpa

|

||

|

Main vibration form

|

Platform vibration

|

||

|

Cycle Time

|

15-25 seconds

|

||

|

Vibrating Frequency

|

2800-4500 rolls/minute

|

||

|

Motors Power

|

55.5 KW

|

||

|

Pallet Size

|

950x900mm

|

||

|

Raw Materials

|

crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes.

|

||

|

Applied Products

|

concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc.

|

||

|

Applied Fields

|

widely used in buildings, road pavings, squares, gardens, landscaping, city constructions, etc.

|

||