Pre-Sale Service: IDA engineer team could provide you with design of complete production line. We are owning modern Nano Laboratory and could help clients do test run of your material, generate lab report and guide your actual production.

On-Sale Service: IDA factory will manufacture the good quality machine.

After-sale Service: IDA engineers will be sandby for 24 hrs to provide you with prompt solution. We could send technicians to your factory to help you install the disperser and sand mill, train your workers to operate and help with the debugging.

All wear parts of IDA disperser and sand mill is available at any time you need. Our engineer will provide you with spare parts scheme before sending the grinding mill to help you know when it is needed to change the parts so that to avoid any delay of production due to mill parts.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

IDA

-

Dimension(L*W*H):

-

customizable

-

Power (kW):

-

1 kW

-

Marketing Type:

-

Customized Products

-

Diameter:

-

30-500mm

-

Inter bore:

-

8,10,12,35mm

-

Thickness:

-

1.5,2,2.5,3mm

Quick Details

-

Barrel Volume (L):

-

1000

-

Max. Loading Volume (L):

-

1000 L

-

Weight (KG):

-

10 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

IDA

-

Dimension(L*W*H):

-

customizable

-

Power (kW):

-

1 kW

-

Marketing Type:

-

Customized Products

-

Diameter:

-

30-500mm

-

Inter bore:

-

8,10,12,35mm

-

Thickness:

-

1.5,2,2.5,3mm

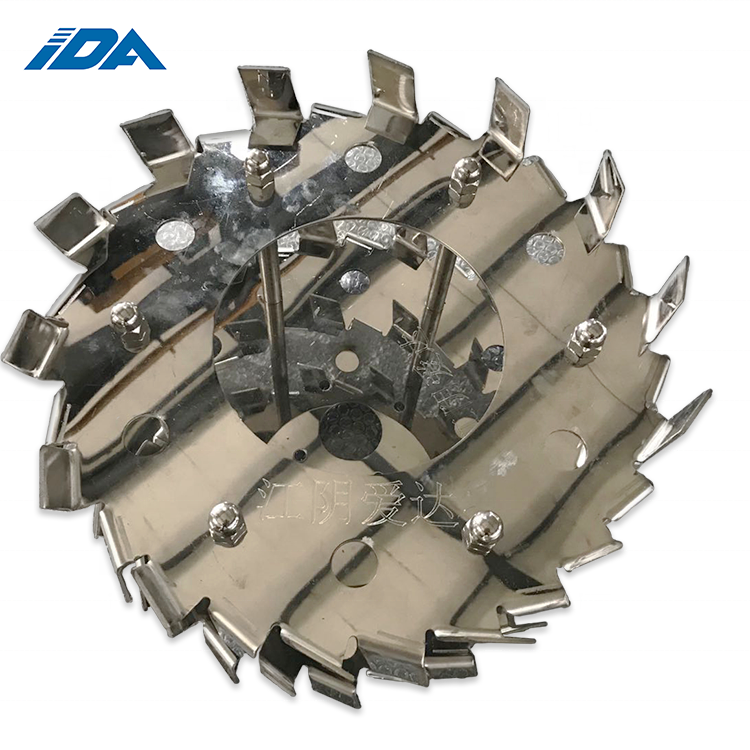

Introduction

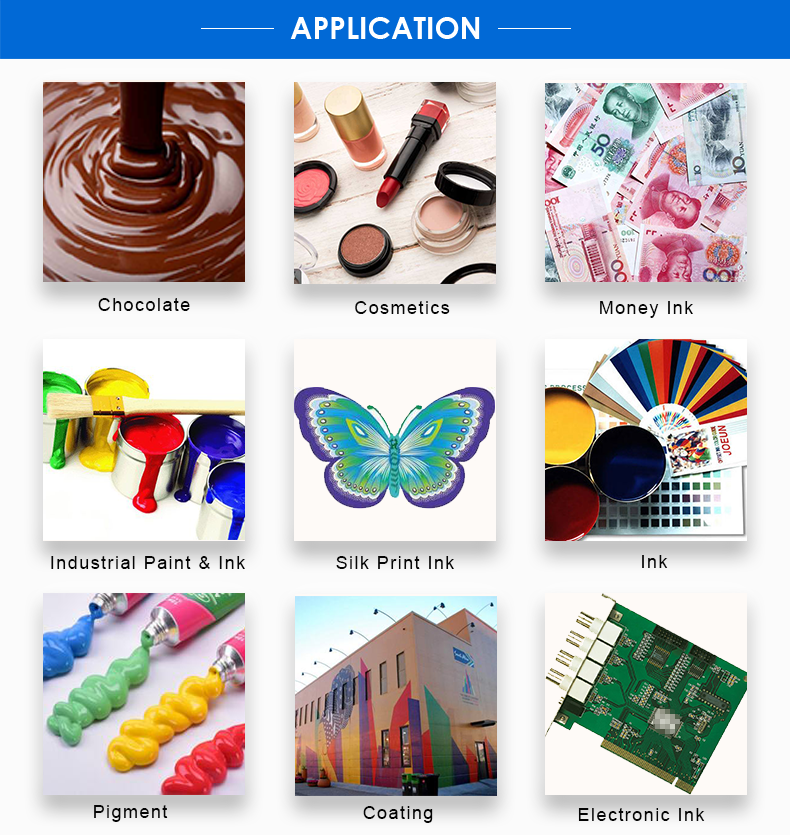

Dispersing Disc is mainly used for pulverizing, stirring and grinding of liquid,emulsion and liquid-solid materials such as coating,pigment,dye,paint,ink,food,adhesive,daily chemicals,etc. It is the conventional accessories for mechanical equipment such as disperser,grinder,mixer,emulsifier,etc.

Working Principle

The dispersing disc is the high speed disperser's accessories,which is connected to the spindle of high speed disperser. When rotating at high speed ,the upper and lower sides of the dispersing disc are in a rotating state,and forming a turbulent zone at 2.5-5mm at the edge.

The upper and lower sawteeh of the dispersing disc are used for high-speed shearing, impacting, grinding and dispersing to the materials such as coating, paint, dry powder and solid-liquid,etc,In order to achieve a state of mixing,dissolution,dispersion and refinement quickly.

According to the position of dispersed teeth:

Peripheral teeth dispersing disc

Internal teeth dispersing disc

According to the surface of the dispersing disk:

Single layer dispersing disc

Double-layer dispersing disc

Multi-layer dispersing column

Main Features

1,High strength, sturdy and durable.

2,Flexible production according to the power of the disperser, simple and practical.

3,Easy to replace, easier to clean, non-pollution.

4,Good dispersing effect.

5,Large shear area.

6,crush materials in short time,realize instantaneous pulverization,rapid dissolution and mixing