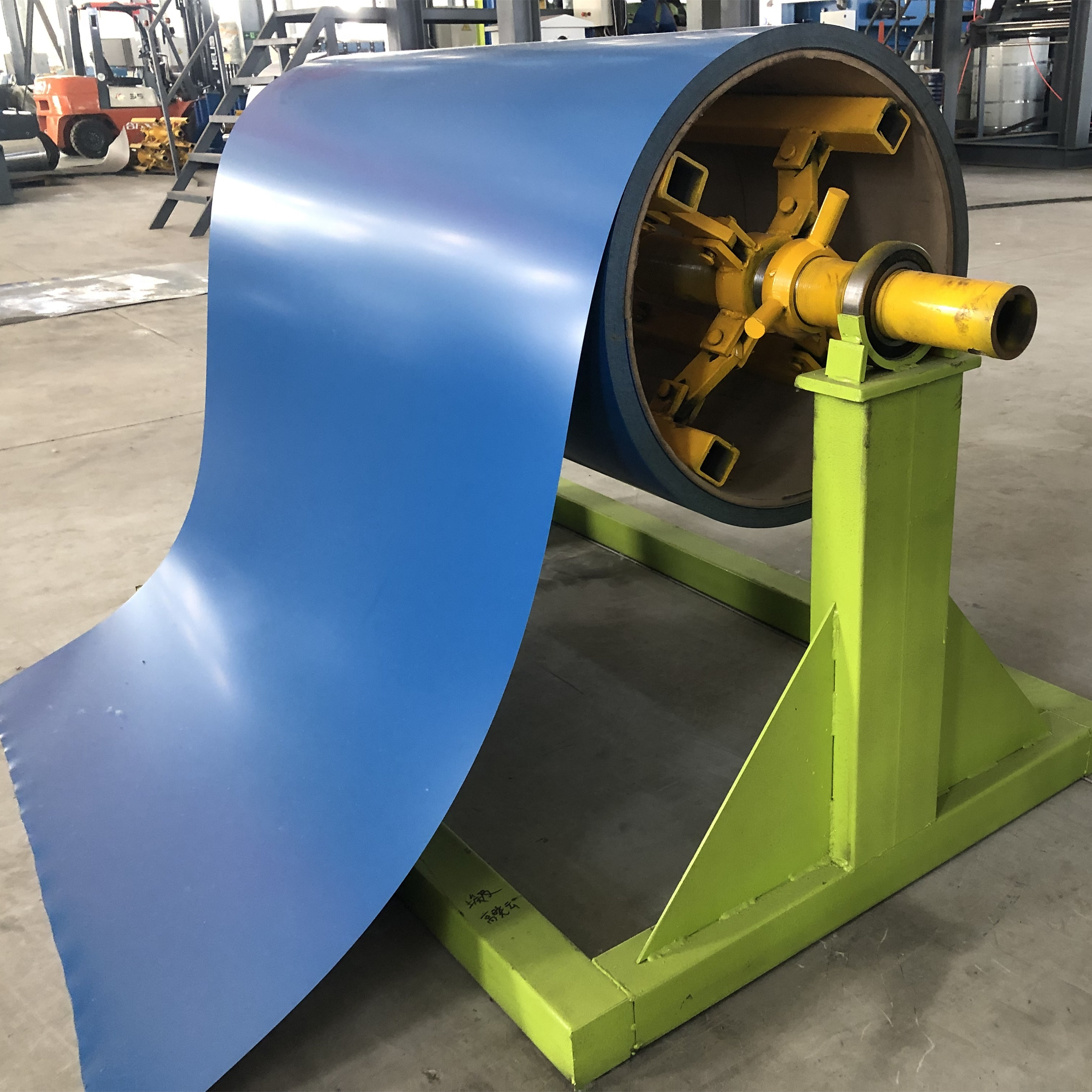

horizontal decoiler usually used for roof sheet roll forming machine.

Horizontal decoiler by tonnage, normally there have 5 Tons, 8 Tons, 10 Tons type.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.2-1.0mm

-

Place of Origin:

-

Hebei

-

Brand Name:

-

ZTRFM

-

Voltage:

-

no

-

Dimension(L*W*H):

-

0.5*1.2*1.5m

-

Weight:

-

500 kg

-

Marketing Type:

-

New Product 2023

-

Core Components:

-

Other

-

After-sales Service Provided:

-

life time technology service

-

Color:

-

costomized

-

Usage:

-

uncoil

-

material type:

-

steel/PPGI/zinc

-

Thickness:

-

0.3-0.8mm

-

Advantage:

-

Simple Operation

-

Name:

-

decoiler

-

type of shipping:

-

less than container load

-

way of packing:

-

wooden box package

Quick Details

-

Type:

-

Decoiler

-

Tile Type:

-

Steel

-

Production Capacity:

-

35m/min

-

Rolling thinckness:

-

0.2-1.0mm

-

Place of Origin:

-

Hebei

-

Brand Name:

-

ZTRFM

-

Voltage:

-

no

-

Dimension(L*W*H):

-

0.5*1.2*1.5m

-

Weight:

-

500 kg

-

Marketing Type:

-

New Product 2023

-

Core Components:

-

Other

-

After-sales Service Provided:

-

life time technology service

-

Color:

-

costomized

-

Usage:

-

uncoil

-

material type:

-

steel/PPGI/zinc

-

Thickness:

-

0.3-0.8mm

-

Advantage:

-

Simple Operation

-

Name:

-

decoiler

-

type of shipping:

-

less than container load

-

way of packing:

-

wooden box package

Product Description

ZTRFM manual decoiler machine Uncoiling machine 5Ton 3Ton

Decoiler is an evitable part of roofing roll forming machine to hold and safely pay off the steel strip. A decoiler, also call uncoiler, unwinds steel coil, which can be feed into continuously running machineries such as roll former or automatic punches.

Decoiler machine is suitable for all kinds of coil material feeding and the decoiler can work with straightener. .

Decoiler machine is suitable for all kinds of coil material feeding and the decoiler can work with straightener. .

Where is manual decoiler different from hydraulic decoiler?

|

Manual decoiler have no power and coil have to be drag into main roll former passtively.

|

|

|

Hydraulic decoiler can make the coil turn automatically.

|

|

||||

|

Manual type need expand and shrink core by hand wheel.

|

|

|

Hydraulic type can expand the core to fit the coil diameter by PLC control system.

|

|

||||

|

The hydraulic type can automatically feeding the material into machine, that can reduce the machine abrasion.

|

|

|

|

|

||||

|

Hydraulic decoiler in a high price and manual type is in a lower level.So you can choose suitable type according to your budget.

|

|

|

|

|

||||

Manual decoiler classify

Manual decoiler often be used with roll forming machine.

Diffieren type decoiler have diffierent usage.

By usage, there have vertical type and horizontal type.

Manual decoiler often be used with roll forming machine.

Diffieren type decoiler have diffierent usage.

By usage, there have vertical type and horizontal type.

Products Display

horizontal decoiler

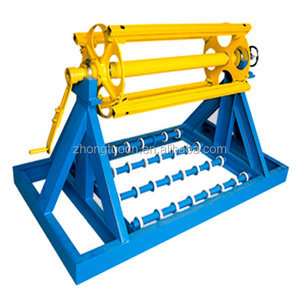

vertical type

Vertical type decoiler usually used for light keel roll forming machine

and other kinds of small narrow machine and usually devided into 1.5Tons, 3Tons, 5Tons type.

and other kinds of small narrow machine and usually devided into 1.5Tons, 3Tons, 5Tons type.

Why Choose Us

Hot Searches