- Product Details

- {{item.text}}

Quick Details

-

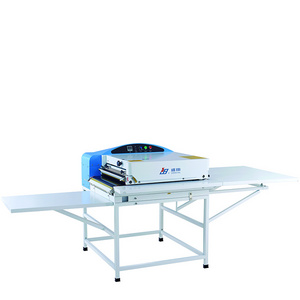

Brand Name:

-

SHANGJIN

-

Mold:

-

HP-1800AES12

-

Power supply:

-

3P/380V

-

Certificates:

-

CE

-

Application:

-

Textile Industry/garment factory

-

Packaging Details:

-

Free fumigating wooden case

-

Motor:

-

400W

-

Max Pressure:

-

6 kg/c㎡

-

Fusing speed:

-

5-20min

-

L*W*H Dimensions:

-

3950*2370*1600

-

After Warranty Service:

-

Online support

Quick Details

-

Weight (KG):

-

1150

-

Marketing Type:

-

Hot Product 2021

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SHANGJIN

-

Mold:

-

HP-1800AES12

-

Power supply:

-

3P/380V

-

Certificates:

-

CE

-

Application:

-

Textile Industry/garment factory

-

Packaging Details:

-

Free fumigating wooden case

-

Motor:

-

400W

-

Max Pressure:

-

6 kg/c㎡

-

Fusing speed:

-

5-20min

-

L*W*H Dimensions:

-

3950*2370*1600

-

After Warranty Service:

-

Online support

Product Application

1,For the woven,knitted fabrics fusing.

2,Fusing for the whole roll of fabric and interline.

3,Double roller and double compressed air press system adopted,two times press and adhesion force more even,the best peeling strength of the product.

Feature:

1,Continuous fusing system increases the productivity.

2,Equipped with the wheels for convenient mobility.

3,PCB and micro switch control the upper and lower belts automatically and extends duration of the belt.

4,Pressure rollers are made by silicone,which ensure the power of pressure giving is stable and equal.

5,Electronic temperature constant temperature control system, temperature accurately.

6,There are 9 heaters to distribute the heat evenly and can be used to all fabrics.

7,Equip with stronger vacuum system for cooling which can let the fabric in shape immediately.

8,Equipped with automatic cooling timing shutdown system.

9,Pneumatic double roller pressing,the pressure of which can be adjusted separately.

10,Special-designed clean rod to clean the belt completely,and it is easy for replacement once the rod gets dirty.

11,With frequency conversion mechanic to control speed, running smoothly and more energy saving.

12,Optional:Basket of cloth/Automatic feeding machine;Winding machine/Infrared edge cloth rolling machine.

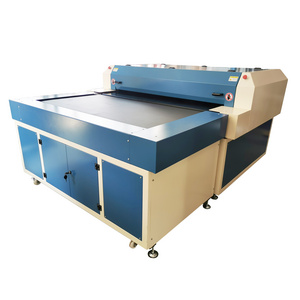

TB series feeding machine parameters

Model 1800

Power 1P/220V 50Hz

Power 180W

Appearance size 1900*1000*1000

There are 2 sets of cloth rack for collecting cloth, which is easy to operate and saves time and effort.

Model:JB--C1800

Power:220v50Hz

Power:750W

Opposite side:U type infrared opposite sideAppearance size 2730*1300*980

1,This machine equipped with edge control system to ensure the fabric rewind neatly.

2,Measurement: Equip with mechanical counter to ensure the measurement precisely, more accurately.

3,With fabric rolling tension adjustment.

4,With movable wheel for moving easily.

4 rollers and double compressed air press system adopted,two times press and adhesion force more even,the best peeling strength of the product.

Equip with stronger vacuum system for cooling which can let the fabric in shape immediately.

Machine operation panel and operating parts

1,Outside pressure gauge of pressure roller

2, Inside pressure gauge of pressure roller

3,Upper temperature controller

4,Speed frequency display panel

5,Start button

6,Stop and jog buttons

7,Outside pressure regulating valve of pressure roller

8,Inside pressure regulating valve of pressure roller

9,Lower temperature controller

10,Speed regulator

11,Delayed automatic shutdown switch

Pneumatic double roller pressing,the pressure of which can be adjusted separately

Side plate easy disassembly

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate