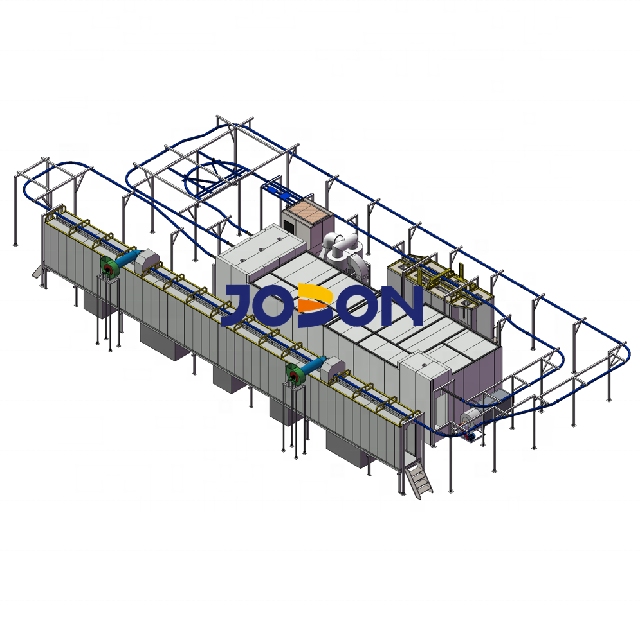

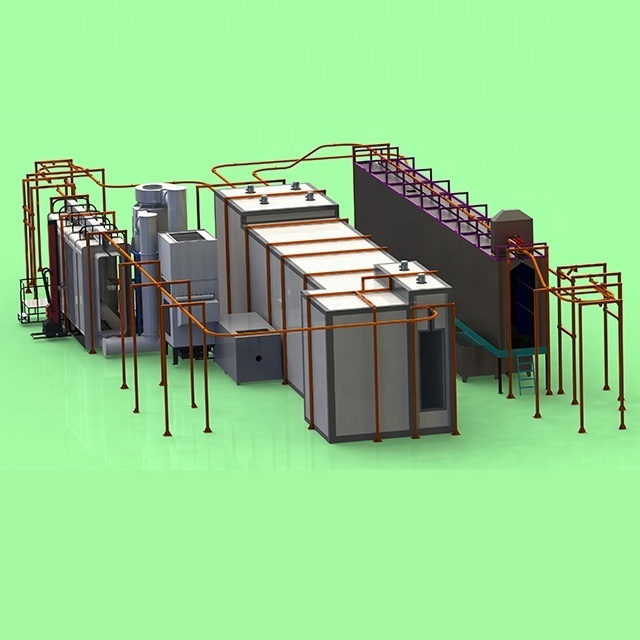

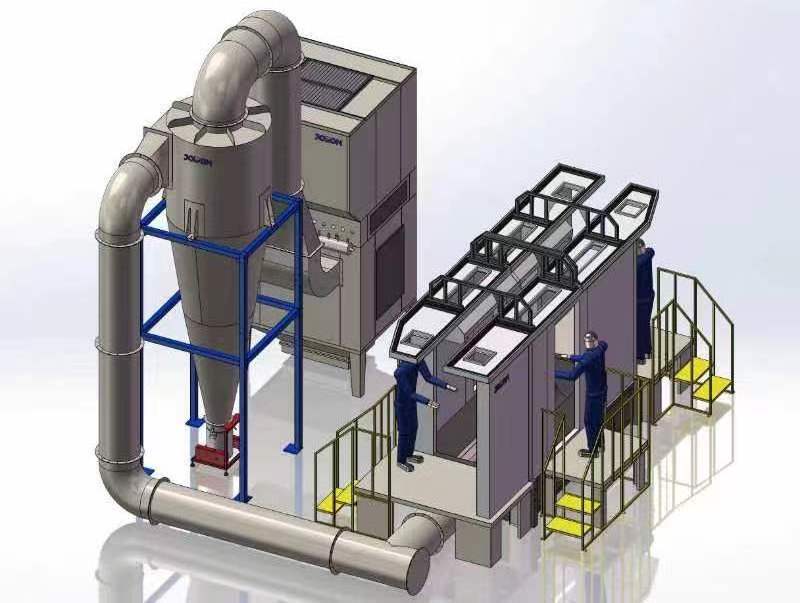

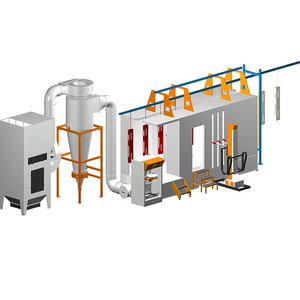

The automatic powder coating booth is used for spraying and collecting powder for reuse.

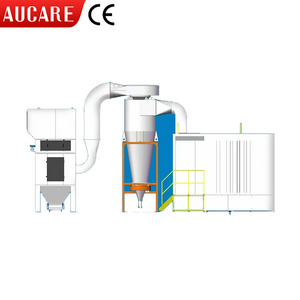

There are many choices for booth materials from the standard level to the top level, including electrolytic galvanized steel,

stainless steel, and PVC.

PVC booth with stainless steel mono cyclone system is the highest booth system you can choose.

stainless steel, and PVC.

PVC booth with stainless steel mono cyclone system is the highest booth system you can choose.