- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Polybett

-

Product name:

-

HPL wall panel

-

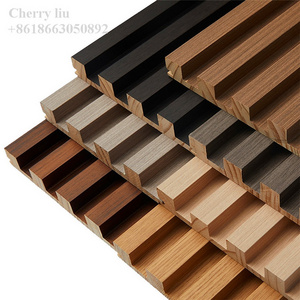

Color:

-

Solid, Woodgrain, Metal, Stone,Cloth,Nature

-

Finishes:

-

Texture/matte/glossy

-

Thickness:

-

6mm-12mm(Most Popolar)

-

Advantage:

-

Fireproof+waterproof+anti-scratch

-

Material:

-

Phenolic hpl compact laminate board

Quick Details

-

Project Solution Capability:

-

graphic design

-

Application:

-

Hospital

-

Design Style:

-

Modern

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Polybett

-

Product name:

-

HPL wall panel

-

Color:

-

Solid, Woodgrain, Metal, Stone,Cloth,Nature

-

Finishes:

-

Texture/matte/glossy

-

Thickness:

-

6mm-12mm(Most Popolar)

-

Advantage:

-

Fireproof+waterproof+anti-scratch

-

Material:

-

Phenolic hpl compact laminate board

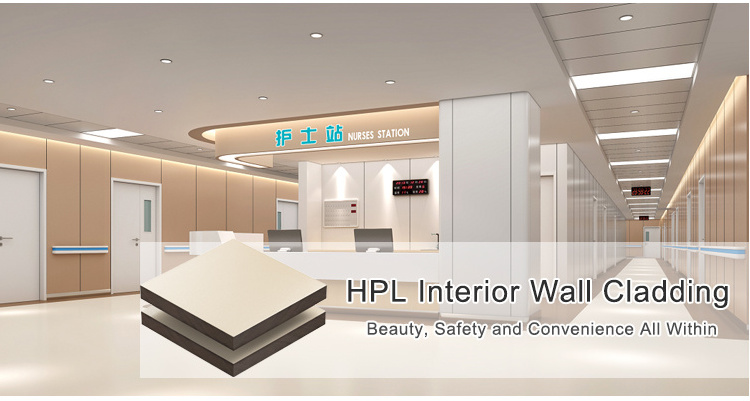

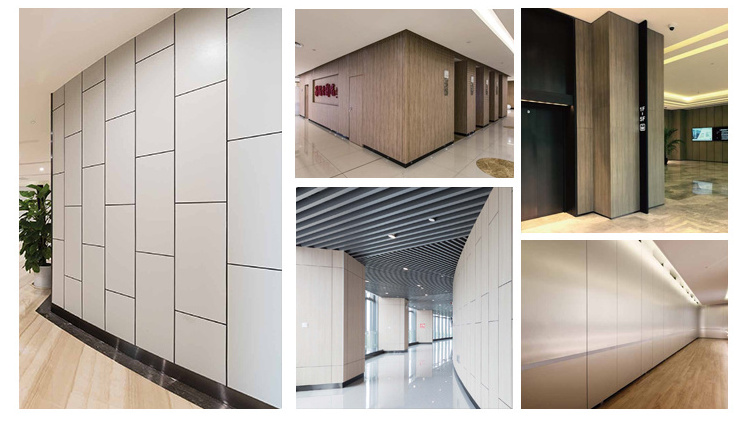

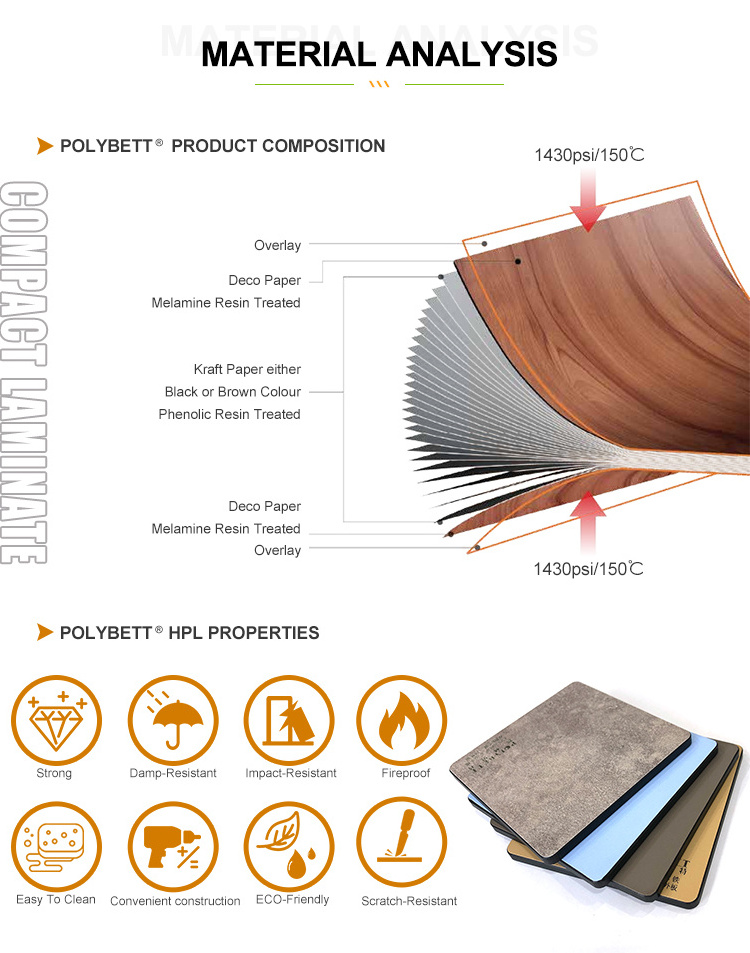

HPL interior wall panels are High-Pressure Laminate panels used for interior wall cladding. They are made by combining multiple layers of resin-impregnated kraft paper under high pressure and heat. HPL panels are highly durable, scratch-resistant, and have excellent resistance to moisture, heat, and chemicals. They come in a wide range of colors, patterns, and textures, making them suitable for various interior design styles. HPL panels are easy to clean, maintain, and install, and provide sound and thermal insulation. They are commonly used in commercial and residential spaces, such as offices, hospitals, hotels, and homes, to create attractive and functional interior wall surfaces.

Material Analysis

Material Information

|

Name

|

HPL interior wall panel

|

|

Size

|

1220*1830mm(4'x6'), 1220*2440mm(4'x8'), 1220*3660mm(4'x12'), 1300*2800mm(4.3'x9'), 1300*3050mm(4.3'x10'), 1530*1830mm(5'x6'),1530*3050mm(5'x10'), 1530*3660mm(5'x12') , 1830*1830mm(6'x6'), 1830*2440mm(6'x8') , 1830*3660mm(6'x12'),1830*4270(6'x14'),

Size can be customized.

|

|

Color

|

Solid, Woodgrain, Metal, Stone,Cloth,Nature

|

|

Thickness

|

6mm-12mm(Most Popolar)

|

|

Surface

|

Texture,(Most Popolar), Matte,Glossy, Embossed,T, S, J, X, M, F, NT, D8, T3, T4, SP, PX

|

Installation System

Scene Adaptation

Particularly suitable for applications such as laboratories, hospitals, medical centers,school and dining halls.

Project Case

About Us

Changzhou Zhongtian Fire-Proof Decorative Sheets Co., Ltd. is one of China's largest manufacturers of high-pressure laminate decorative fire-resistant boards with facilities covering an area of 40,000 square meters. Over the years we collected rich experiences and established the famous brands,"Polybett",With capabilities to produce balance boards, bent boards, metallic panel and fire-resistant boards, our unique design concepts and individualized styles are famous in the domestic industry.

Incomming quality inspection:

Confrim order---purchase paper----paper delivery to factory----paper transfer to warehouse----weighting, checking the quality and appearance---Qualified: transfer to the workshop and wait for production.Disqualification:transfer into the disqualification area, inform and back to the paper factory.

Press machine inspection:

Laminate out of the machine---inspect the sheets thickness---Qualified:transfer to the next production process.

Disqualification:transferinto the disqualification area,waiting to be processed.

Pre-delivery Inspection:

The laminate transfer into the semi-finished products warehouse after cutting rough edge---inspect the appearance, size and thickness---Qualified: transfer into the finished products warehouse, waiting for packing. Disqualification:transfer into the disqualification area,waiting to be processed.

Press machine inspection:

Laminate out of the machine---inspect the sheets thickness---Qualified:transfer to the next production process.

Disqualification:transferinto the disqualification area,waiting to be processed.

Pre-delivery Inspection:

The laminate transfer into the semi-finished products warehouse after cutting rough edge---inspect the appearance, size and thickness---Qualified: transfer into the finished products warehouse, waiting for packing. Disqualification:transfer into the disqualification area,waiting to be processed.

FAQ

1.Q: Are you trading company or manufacturer ?

4.Q:What is your terms of payment?

5.Q. What is your terms of delivery?

A: We are factory.

2.Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-25 days if the goods are not in stock, it is according to quantity.

3.Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

4.Q:What is your terms of payment?

A: 1.T/T 30% as deposit, and 70% pay against the copy of B/L. 2.L/C at sight. 3.D/P at sight.

5.Q. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Hot Searches